operation of cnc lathe machine Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various . wholesale cnc milling parts,SLD Precision offers top-quality CNC milling parts for various applications. With our advanced CNC milling capabilities, we deliver precise and complex .

0 · turning operations on lathe machine

1 · parts of cnc lathe machine

2 · cnc lathe work

3 · cnc lathe process

4 · cnc lathe parts

5 · cnc lathe machine working

6 · centering operation on lathe machine

7 · center lathe operations

We would like to show you a description here but the site won’t allow us.

What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.CNC Turning is a fundamental operation performed on a lathe machine, .Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various .

form 1099 r with distribution code 7 in box 7

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by . Machinists use CNC lathe machines to complete various metalworking projects, usually those high-volume components that require accuracy and repeatability. In contrast, traditional engine lathes have been . A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined .What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, .

CNC lathe machines have several essential components that work together to achieve precise and efficient machining operations. Understanding these components is crucial for grasping the functionality and operation of a CNC .

CNC Turning is a fundamental operation performed on a lathe machine, characterized by the rotational motion of a workpiece against a cutting tool. This combination of motions produces a cylindrical shape, with the result . Everything You Need to Know. A CNC lathe, or turning center, is a versatile tool used in various manufacturing processes. It consists of a spindle that rotates a workpiece and a tool block or turret to hold a cutting tool or stick . CNC lathe machine produces the most accurate products as compared to the other type of the lathe machine. In CNC Lathe machine program are being fed to the computer system which controls the overall working of the .

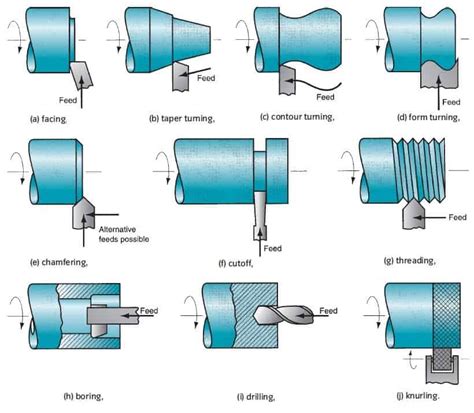

CNC Lathe Main Parts. Now, let’s see the main components of a turning centre. Headstock. The headstock of a CNC lathe makes up the front section of the machine. This is where the driving motor is along the . Types of Lathe Machine Operations. The lathe machine operations are classified into three main categories and are as follows. Following are the Lathe machine operations done either by holding the workpiece between centers or by a chuck: Turning Operation Plain or . Recently, the CNC lathe machine, a precision machine tool machinists employ for various woodturning and metalworking projects, has become the go-to lathe for machining high-volume components that require accuracy and repeatability and the most complex projects. . The current tool path is highlighted while the machine is in operation without .*Duties* - Operate and maintain CNC lathe machines to fabricate precision parts - Set up and adjust machine settings based on blueprints and job requirements - Monitor machine operations to ensure quality production - Inspect finished products for accuracy and quality control - Perform basic maintenance on machines and tooling - Read and .

View all C.E. MACHINE jobs in Wichita, KS - Wichita jobs - CNC Lathe Operator jobs in Wichita, KS Salary Search: CNC LATHE OPERATOR – MULTIPLE SHIFTS AVAILABLE salaries in Wichita, KS See popular questions & answers about C.E. MACHINE

What are the common applications of reaming in lathe machine operations? Reaming is a crucial operation in lathe machine operations and is commonly used to enhance the accuracy and finish of cylindrical holes. It involves enlarging and smoothing existing holes, making them more precise and removing any irregularities. Operation & processes of a CNC lathe Machine A basic CNC turning machine rotates the material it cuts while operating on two axes. Because the rotation of the material is usually referred to as ‘turning,’ CNC lathes are sometimes referred to as CNC turning machines. The inside and outside of the component may be machined using CNC turning . CNC Lathe Machine Operations. Depending on the machine type and the workpiece, there are several operations that are carried out on a lathe. For instance, drilling, threading, boring, and facing are some of the most common operations.

TESDA TRAINING REGULATIONS FOR CNC LATHE MACHINE OPERATION NC II COURSE The TESDA Course in CNC Lathe Machine Operation NC II consists of competencies that a person must achieve to write basic CNC Lathe machine program, set-up machine, workpiece and cutting tools and perform basic CNC lathe machine operations. A student who has achieved .

Regarding the operation of a CNC lathe, the most relevant part of the operation is: The CNC machine controller receives instructions from the computer and, using its own software, converts the instructions into electrical signals to activate the motors which, in .A CNC lathe is a versatile tool that can be used for many applications, from simple turning operations to complex milling on a lathe. When selecting a CNC lathe, it's crucial to consider factors such as the size of your projects, the materials you'll be working with, and your budget .

Lathe Machine Fundamentals: This section will provide a historical overview of lathe machines, discuss the various types, and explore the essential components that make these machines work.; Lathe Grooving Tools: To perform grooving operations effectively, machinists require the right tools.This section will delve into the world of lathe grooving tools, exploring types, . CNC Lathe vs CNC Milling: The Difference in Operation. When it comes to CNC machining, understanding the difference between a CNC lathe and CNC milling is crucial. While both machines are used to shape materials, their operation varies significantly. CNC Lathe. In a CNC lathe, the material rotates against stationary cutting tools. This involves choosing the right type of CNC machine and configuring certain operations before the machining operation begins. Selecting the right machine depends on the workpiece, the complexity of product .These basic components form the core structure of a CNC lathe machine, allowing for precise and efficient machining operations. The SYIL Machine Tools brand, known for its commitment to quality and sustainability, develops and .

Features of CNC Lathe The tool or material moves. Tools can operate in 1-5 axes. Larger machines have a machine control unit (MCU) which manages operations. Movement is controlled by a motors . Feedback is .Experience in CNC Lathe machine setup and operation. Setup, machine, and measure to specification. CNC Machine Set up/Operator/ Programmer. New. LaunchNW. Portland, OR. Typically responds within 1 day. - an hour. Full-time. 40 to 50 hours per week. Monday to Friday +8. Easily apply. B&S collets are better than 5C collets for controlling part length, so they are favored for screw machine work. The VBS is otherwise like the Hardinge DSM59, which has a 5C spindle. . Hardinge called them second operation lathes. The name implies that they are used to add some finishing operation to parts initially made on a different machine .What is a CNC Lathe Machine A lathe is a machine tool used in metalworking. It can be used to create many different shapes of metal. The main function is to create 3-dimensional shapes by cutting away material on a rotating workpiece. A CNC Lathe Machine is a type of machine that uses computer controls to precisely turn raw materials into various types of parts with .

forming sheet metal

Lathe Machines. Types of Lathes:. Center Lathe Engine Lathe Bench Lathe Capstan & Turret Lathes Automatic Lathes Multi Spindle Lathes Vertical Turret Lathes CNC Lathes. Lathe Machines. Kinematic Scheme of Lathe Machine. Speed Gear Box Headstock. Tool Post. Saddle. Chuck. Tail Stock. 2.41k views • 18 slidesResources and training programs available to learn CNC lathe machine operation . Importance of skilled operators in maximizing the potential of CNC lathe machines . Section 9: Conclusion\ In conclusion, CNC lathe machines have revolutionized the manufacturing industry, playing a crucial role in improving productivity, accuracy, and efficiency . What exactly is a CNC lathe machine? A CNC lathe, also known as a CNC turning machine, is a type of machine that rotates a workpiece on a spindle while a fixed cutting tool shapes the material. Unlike traditional machines, a CNC lathe operates based on coded instructions programmed into a computer, which controls the movements of the components. CNC lathe machining is a process where a computer controls a lathe machine to perform various operations, ensuring precision and consistency. How does a CNC lathe differ from a traditional lathe? While both machines perform similar operations, a CNC lathe is automated and driven by computerized instructions, ensuring higher precision and .

Turning operations on a lathe machine are crucial for achieving precise and accurate results in metalworking. By understanding the fundamentals of turning, including its definition, various types, and important considerations, machinists can leverage this powerful operation to shape materials according to specific requirements. With practice . The time it takes to set up a CNC lathe machine can vary depending on several factors, such as the complexity of the job, the operator's experience, and the condition of the machine. In general, setting up a CNC lathe machine can take anywhere from a few minutes to a couple of hours.

3rd Shift Skilled CNC Lathe and Mill Machine Operator. C & S Machine & Manufacturing Corporation 4.5. Louisville, KY 40216. Up to an hour. Full-time. 40 hours per week. Monday to Friday +4. Easily apply *Now offering retention bonuses!* We're currently seeking qualified candidates for the following shift: * 3rd-Sunday-Thursday 11:00pm-7 .

turning operations on lathe machine

fortis metal bracket

parts of cnc lathe machine

cnc lathe work

General Manufacturing Company offers a wide variety of contract manufacturing including CNC milling, turning, assembly, and many other services for your custom projects or OEM needs. We offer several different options for getting your brand .

operation of cnc lathe machine|cnc lathe parts