add ground wire to junction box All ground splices must be done with the same rules as any other splices: inside a junction box or using some sort of splice listed for use outside of a box. For details, see the .

What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or stainless steel metal sheets are too thin, we recommend that you use the TIG technique.

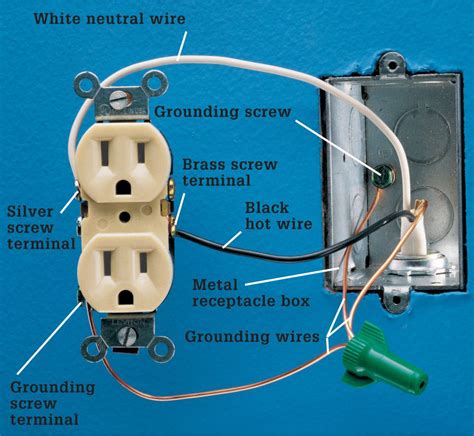

0 · wiring a receptacle metal box

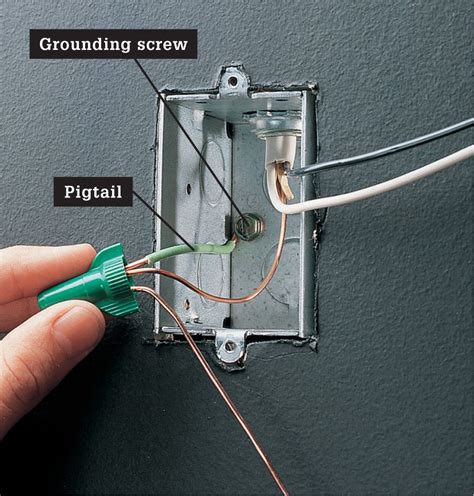

1 · pigtail ground wire metal box

2 · grounding wire for metal box

3 · grounding screws for metal boxes

4 · grounding outlet to metal box

5 · grounding outlet into metal box

6 · grounding a receptacle metal box

7 · ground wire touching metal box

Stick Welding Amperage for Thin Sheet Metal Welding. Use 50-ampere current when welding with E6013 diameter 5/64 inch. For smaller gauge sheets such as 20 or 22 lower the ampere before weld. Welding shall not be .

However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom . Note: If you’re working with a metal box, you’ll need to add a pigtail (a separate 4- to 6-inch length of ground wire) to the other grounds and connect it to the green ground screw located inside the box. Wrap the pigtail clockwise . There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding .

Join the bare copper (or green insulated) ground wires together first. If the box is metal, add a pigtail—a 6-inch length of the same type of ground wire—to the ground wire . Adding a ground wire junction box is a critical step in installing electrical wiring safely and correctly. Ground wires are used to provide an alternate route for electricity to . All ground splices must be done with the same rules as any other splices: inside a junction box or using some sort of splice listed for use outside of a box. For details, see the .

However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground. Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be machine threaded and green in color.

Note: If you’re working with a metal box, you’ll need to add a pigtail (a separate 4- to 6-inch length of ground wire) to the other grounds and connect it to the green ground screw located inside the box. Wrap the pigtail clockwise around the screw and tighten the screw. There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding jumper. A bonding jumper is a piece of metal connected to the grounding screw on the box and then attached to the ground electrical system. Join the bare copper (or green insulated) ground wires together first. If the box is metal, add a pigtail—a 6-inch length of the same type of ground wire—to the ground wire connection, then connect the loose end of the pigtail to the ground screw on the box.

wiring a receptacle metal box

Adding a ground wire junction box is a critical step in installing electrical wiring safely and correctly. Ground wires are used to provide an alternate route for electricity to bypass faulty insulation, protect against electric shocks, and ensure proper grounding of . All ground splices must be done with the same rules as any other splices: inside a junction box or using some sort of splice listed for use outside of a box. For details, see the National Electric Code, NFPA 70 (2014) Article 250 — Grounding and Bonding .If you have a conventional plastic box that houses your spliced wires, you need to ground the box by connecting the ground wire to a grounding screw using the pigtail method. Use Of Ground Wire Coming From Junction Box In this video you'll learn how to wire junction boxes correctly. You'll also se. Nothing is more dangerous and aggravating than loose wires in a junction box.

After connecting the wires, secure them neatly inside the junction box. Additionally, if the box is made of metal, ensure proper grounding by connecting a ground wire to the grounding screw provided in the box. This step is crucial for safety and compliance. However, this may not be necessary. The device has metal tabs (ears) where you screw it into the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground.

Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be machine threaded and green in color.

Note: If you’re working with a metal box, you’ll need to add a pigtail (a separate 4- to 6-inch length of ground wire) to the other grounds and connect it to the green ground screw located inside the box. Wrap the pigtail clockwise around the screw and tighten the screw. There are a few different ways to ground a metal junction box. One is to use screws and clamps to attach the grounding wire to the box. Another way is to use a bonding jumper. A bonding jumper is a piece of metal connected to the grounding screw on the box and then attached to the ground electrical system. Join the bare copper (or green insulated) ground wires together first. If the box is metal, add a pigtail—a 6-inch length of the same type of ground wire—to the ground wire connection, then connect the loose end of the pigtail to the ground screw on the box.

Adding a ground wire junction box is a critical step in installing electrical wiring safely and correctly. Ground wires are used to provide an alternate route for electricity to bypass faulty insulation, protect against electric shocks, and ensure proper grounding of . All ground splices must be done with the same rules as any other splices: inside a junction box or using some sort of splice listed for use outside of a box. For details, see the National Electric Code, NFPA 70 (2014) Article 250 — Grounding and Bonding .

If you have a conventional plastic box that houses your spliced wires, you need to ground the box by connecting the ground wire to a grounding screw using the pigtail method. Use Of Ground Wire Coming From Junction Box In this video you'll learn how to wire junction boxes correctly. You'll also se. Nothing is more dangerous and aggravating than loose wires in a junction box.

pigtail ground wire metal box

cnc machine leveling pads

cnc machine lathe parts

Position your box between the electrodes where you need to weld. This area should be on your tabs. Pinch down on your metal by slowly pressing down on your foot pedal and be sure you .

add ground wire to junction box|grounding outlet to metal box