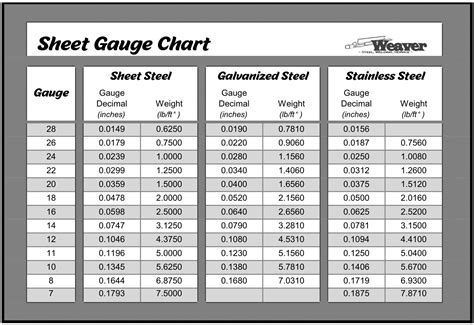

ductwork sheet metal gauge Gauge and Absolute Pressures: Gauge pressure is indicated on the gauge; absolute pressure is the total of the indicated gauge pressure plus atmospheric pressure. So I was in a discussion the other day about the thickness of automotive body panels these days. I was under the impression that they were 18 gauge for the most part. Someone else concurred and said that all sheet is presently high strength 22 or 24 gauge.

0 · typical gauge for ductwork

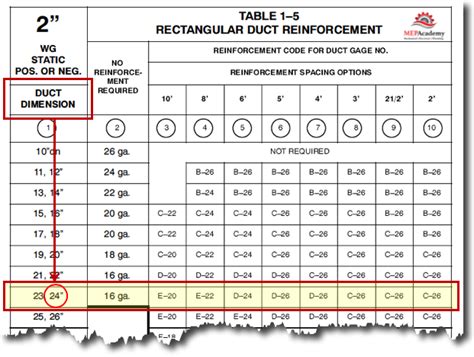

1 · smacna sheet metal gauge chart

2 · ductwork gauge chart

3 · duct size and gauge chart

4 · duct gauge weight kg m2

5 · duct gauge thickness chart

6 · duct gauge chart sheet metal

7 · 26 gauge vs 30 duct

CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.

Ductwork sheet metal gauges: Thickness of sheet metal used in ductwork.“STD” denotes standard (nonvariable volume) air duct construction requirements (regardless of actual velocity level) for compliance with this document for all cases in which the designer .Gauge and Absolute Pressures: Gauge pressure is indicated on the gauge; absolute pressure is the total of the indicated gauge pressure plus atmospheric pressure.The sheet metal gauge calculator is a valuable tool in the HVAC industry as it helps engineers, technicians, and contractors to accurately determine the thickness of sheet metal, which is critical for designing and installing HVAC .

typical gauge for ductwork

smacna sheet metal gauge chart

Free Ductwork Tables for Sizing and Construction of HVAC Air Ducts. The table below can be used to compare equivalent diameters for rectangular and round circular ducts , ductwork sizing , friction loss, sheet . SMACNA (Sheet Metal & Air Conditioning Contractors National Association) is the industry leader in setting the standards for the thickness (gauge), reinforcement, joints and seams, along with various other . Generally, the thickness of HVAC ducts is standardized into 0.5 mm, 0.6 mm, 0.8 mm, 1.0 mm and 1.2 mm. The corresponding duct gauges are 26, 24, 22, 20 and 18. The most common duct thickness is 22 gauge or 0.8 mm.

Spiral Manufacturing Co., Inc. single-wall, rectangular duct fittings are factory fabricated to furnish you with a high-quality line of products in a broad range of standard sizes. To minimize field assembly costs, rectangular duct is supplied .

A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch. Gauge thickness applies differently depending on the . International Mechanical Code Table 603.4 Round ducts and enclosed rectangular ducts 14 inches or less minimum thickness 0.0157 equivalent galvanized gauge size 28. Depending on what size duct will determine the gauge required IRC TABLE M1601.1.1(2) GAGES OF METAL DUCTS AND PLENUMS USED FOR HEATING OR COOLING DUCT SIZE GALVANIZED ALUMINUM Minimum Thickness (inches) Equivalent Galvanized Gage No. Minimum Thickness (inches) Round ducts and enclosed rectangular ducts 14 inches or .

steel mobile security boxes

ductwork gauge chart

steel pencil box

Sounds to me that the guy with the 30 gauge may be buying it from a supply house who sells it pre made.I dont know to many sheet metal shops who make duct work in 30.I prefer 26 myself and think a sheet metal shop that makes it in house is much better than the pre made. HVAC colleagues, I'm looking for the chart/table that states the sheetmetal ductwork minimum gage based on the duct width. Got Smacna, NFPA and Trane manuals for duct fabrication and it isn't within the charts and tables in these manuals. Where can I find it? Thanks in advance. JC Iron is not steel. Galvanized sheet metal for air ducting is cold rolled steel sheet with a coating of zinc. For sheet metal, so far as I know, it is electroplated - not dip coated. It is called 'galvanized' because the zinc and steel is preserved by sacrificing the zinc - . 1st Company: 26 Gauge 2nd company: 24 gauge 1st company: hard pipe in first 6 ft of flex 2nd company: foil back flex, metal outer covering 1st company: Trane XB13c (13 SEER, 80% A.F.U.E.) 2YCC3048A1120A 2nd Company: Trane 13 Seer 4 ton Both companies say their installers have been with them a long time and they do not subcontract.

Another method involves using my Dewalt cordless minigrinder with metal cutoff wheels. It makes a dust cloud, sparks and stinks and you get a wicked burr but it is fast and I can usually cut pretty straight. Wear goggles--not just safety glasses and an N-95 respirator. Ditto on the fwd. pressure to prevent those nasty 'cat's whiskers'.

The first duct job I ever did was made by screwing a piece of flat sheet metal to the bottom of the floor joists. It was 2" wider than the required duct width. Each edge had a slip on it. The sides of the duct were 1" by 8" by 1" channels of sheet metal. I apologize if this is an inappropriate post, but I’ve learned a lot reading this forum so I’d thought I’d ask. I’m having my local sheet metal shop make all my new ductwork, but money is a little tight so I’m making all the fittings, reducers, etc. Is there a formula figuring the length of reducer or just as long as it’s not to . Metal is always best Reissgirl- We had the same issue a while back with the foil back insulation falling off and we found that using a Bostich outward clinch stapler helps and/or spray adhesive on the metal before insulating. Now .

International Mechanical Code Table 603.4 Round ducts and enclosed rectangular ducts 14 inches or less minimum thickness 0.0157 equivalent galvanized gauge size 28. Depending on what size duct will determine the gauge required IRC TABLE M1601.1.1(2) GAGES OF METAL DUCTS AND PLENUMS USED FOR HEATING OR COOLING DUCT SIZE GALVANIZED ALUMINUM Minimum Thickness (inches) Equivalent Galvanized Gage No. Minimum Thickness (inches) Round ducts and enclosed rectangular ducts 14 inches or . Sounds to me that the guy with the 30 gauge may be buying it from a supply house who sells it pre made.I dont know to many sheet metal shops who make duct work in 30.I prefer 26 myself and think a sheet metal shop that makes it in house is much better than the pre made.

duct size and gauge chart

HVAC colleagues, I'm looking for the chart/table that states the sheetmetal ductwork minimum gage based on the duct width. Got Smacna, NFPA and Trane manuals for duct fabrication and it isn't within the charts and tables in these manuals. Where can I find it? Thanks in advance. JC

Iron is not steel. Galvanized sheet metal for air ducting is cold rolled steel sheet with a coating of zinc. For sheet metal, so far as I know, it is electroplated - not dip coated. It is called 'galvanized' because the zinc and steel is preserved by sacrificing the zinc - .

1st Company: 26 Gauge 2nd company: 24 gauge 1st company: hard pipe in first 6 ft of flex 2nd company: foil back flex, metal outer covering 1st company: Trane XB13c (13 SEER, 80% A.F.U.E.) 2YCC3048A1120A 2nd Company: Trane 13 Seer 4 ton Both companies say their installers have been with them a long time and they do not subcontract.

Another method involves using my Dewalt cordless minigrinder with metal cutoff wheels. It makes a dust cloud, sparks and stinks and you get a wicked burr but it is fast and I can usually cut pretty straight. Wear goggles--not just safety glasses and an N-95 respirator. Ditto on the fwd. pressure to prevent those nasty 'cat's whiskers'. The first duct job I ever did was made by screwing a piece of flat sheet metal to the bottom of the floor joists. It was 2" wider than the required duct width. Each edge had a slip on it. The sides of the duct were 1" by 8" by 1" channels of sheet metal. I apologize if this is an inappropriate post, but I’ve learned a lot reading this forum so I’d thought I’d ask. I’m having my local sheet metal shop make all my new ductwork, but money is a little tight so I’m making all the fittings, reducers, etc. Is there a formula figuring the length of reducer or just as long as it’s not to .

steel parts compartment storage boxes

If you’re doing this as a freestanding room divider I think you could use flat metal brackets (?) to connect them on the outside. I did this by not putting the top piece on the one on the bottom, then securing it to the bottom of the other one with L brackets. It makes it look nicer too since there isn't the doubled up piece. In the middle.

ductwork sheet metal gauge|smacna sheet metal gauge chart