design guide sheet metal fabrication Learn the do’s and don’ts of sheet metal fabrication design with RapidDirect’s . There are a variety of types of fabrics you can buy that give you that shiny look you want. One option would be polyester velvet. You get the . See more

0 · sheet metal layout drawings

1 · sheet metal fabrication pdf

2 · sheet metal fabrication handbook pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guidelines pdf

5 · sheet metal design guide pdf

6 · sheet metal design calculations pdf

7 · sheet metal bending chart

Lubricants and release agents are easily removed after metal forming, leaving no or low residue on the tool or workpiece. This avoids impairing subsequent operations like welding or painting, especially for sheet metal forming.

In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design .Learn the do’s and don’ts of sheet metal fabrication design with RapidDirect’s .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with . Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It .

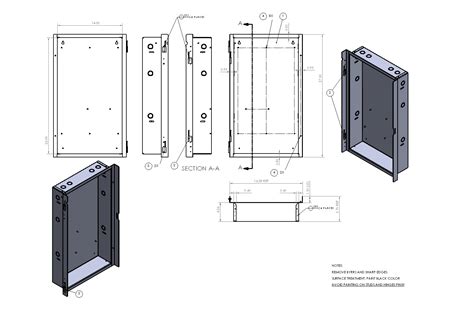

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a .

Download the manufacturing and design guide to sheet metal fabrication and learn all you need to know about sheet metal fabrication in 25 minutes or less. From understanding critical dimensions to mastering cutting-edge software, learn what sets top engineers apart and how you can elevate your own expertise. Dive in to find out! How to be an excellent sheet metal fabrication .

We've compiled our best design tips into this guide to help you understand the sheet metal fabrication process, important design considerations for optimizing your parts for manufacturing, and information about Xometry's sheet metal .Learn the do’s and don’ts of sheet metal fabrication design with RapidDirect’s ebook. Simple guidelines, easy-to-spot mistakes. Get your copy and design smarter. Detailed Guideline: We dive deep into the essentials of sheet metal . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t) Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.Download the manufacturing and design guide to sheet metal fabrication and learn all you need to know about sheet metal fabrication in 25 minutes or less.

From understanding critical dimensions to mastering cutting-edge software, learn what sets top engineers apart and how you can elevate your own expertise. Dive in to find out! How to be an excellent sheet metal fabrication engineer?

We've compiled our best design tips into this guide to help you understand the sheet metal fabrication process, important design considerations for optimizing your parts for manufacturing, and information about Xometry's sheet metal services.

Learn the do’s and don’ts of sheet metal fabrication design with RapidDirect’s ebook. Simple guidelines, easy-to-spot mistakes. Get your copy and design smarter. Detailed Guideline: We dive deep into the essentials of sheet metal fabrication design, ensuring that you have a solid foundation to build upon. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

junction box battery feed

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Bend relief notch 4. A consistent bend orientation is important for ease of fabrication.. 5. The K-factor of your bending design should be chosen from a K-factor chart based on the material type, bend angle, and operation. It typically ranges from 0.25 to 0.50. 6. If your design has offset bends ( Z-shaped), Maintain flange length (on Both Sides)= 3 x thickness(t)

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part.Download the manufacturing and design guide to sheet metal fabrication and learn all you need to know about sheet metal fabrication in 25 minutes or less.

From understanding critical dimensions to mastering cutting-edge software, learn what sets top engineers apart and how you can elevate your own expertise. Dive in to find out! How to be an excellent sheet metal fabrication engineer?We've compiled our best design tips into this guide to help you understand the sheet metal fabrication process, important design considerations for optimizing your parts for manufacturing, and information about Xometry's sheet metal services.

sheet metal layout drawings

junction box clamps

junction box bmw e70

junction box cctv camera

junction box compatible led recessed lights

Common types of CNC machines are CNC lathes for turning cylindrical parts and .

design guide sheet metal fabrication|sheet metal fabrication pdf