design for sheet metal In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Purchase affordable copper flower boxes and metal flower box planters handmade by skilled craftsmen in the USA. We offer galvanized steel flower boxes with colored patina finishes in Garden green, Nantucket blue, and Cape Cod white to look beautifully aged.

0 · sheet metal design pdf

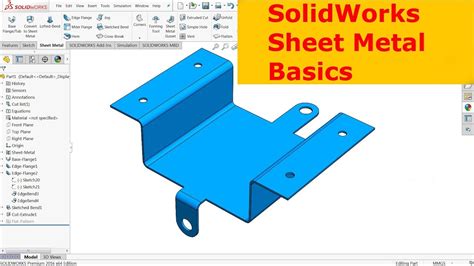

1 · sheet metal design in solidworks

2 · sheet metal design guideline pdf

3 · sheet metal design calculations pdf

4 · sheet metal design and manufacturing

5 · sheet metal basic design guidelines

6 · basics of sheet metal fabrication

7 · basics in sheet metal design

Wire Bending Made Easy The AccuForm modular line of 2D & 3D programmable CNC steel wire benders make virtually any kind of simple or complex parts from round and flat wire. Using AIM’s SmartEditor program, a variety of different shapes can easily be designed.

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

electrical box cutting tool

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence. Let’s get started! 1. Basic on Sheet .

electrical box distance from floor

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to automotive.

electrical box extension ring plastic

Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.

There are a variety of suitable cutting processes for sheet metal, but we’ll be focusing on the most common processes used to prepare sheet metal blanks for bending: waterjet, laser cutting, and punch pressing. Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

In this guide, we delve into the principles of sheet metal design, provide technical insights, and share essential guidelines to help you navigate the world of sheet metal fabrication with confidence. Let’s get started! 1. Basic on Sheet .

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

sheet metal design pdf

sheet metal design in solidworks

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to automotive. Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production. Tolerance is considered the cornerstone of precision in sheet metal fabrication, serving as a measure of the acceptable variation between the initial design and the final product.

sheet metal design guideline pdf

electrical box dimmer switch

electrical box extension 3 1 2 octagon

7-8 Biometric Gun Safe Rifle, Large Gun Safes for Home Rifle and Pistols with Upgraded Control Panel and LED Light, Quick Access Fingerprint Gun Cabinet with Removable Shelf and Gun .

design for sheet metal|sheet metal basic design guidelines