what is a sheet metal part in solid works Sheet metal parts are generally used as enclosures for components or to provide . Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

0 · solidworks sheet metal pdf

1 · solidworks sheet metal examples

2 · solidworks sheet metal drawing pdf

3 · solidworks sheet metal download

4 · solidworks sheet metal basics

5 · sheet metal modeling in solidworks

6 · sheet metal in solidworks 2021

7 · sheet metal 3d sketch solidworks

Get precision CNC machining parts for prototyping and production with RALLY, delivering top-quality metal and plastic components as quickly as 2-3 day. Start with an instant online quote. With over 10 years of experience, RALLY specializes in providing high-precision custom machining parts to clients around the world.

solidworks sheet metal pdf

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed .When designing sheet metal parts, the order preference for use of feature tools .

solidworks sheet metal examples

Sheet metal parts are generally used as enclosures for components or to provide .

Sheet metal is the metal formed into thin and flat pieces, which uses sheets of thickness less than 6 mm. It is one of the main and basic forms of metal working. You can cut .

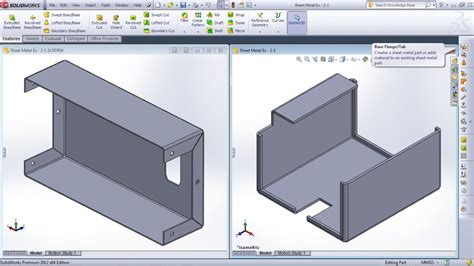

SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .

By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •.

Properties specific to sheet metal parts are calculated and displayed in the Cut-List Properties dialog box. When you assign a custom material to a sheet metal part, you can link the sheet . In this video, we dive into the world of sheet metal parts, exploring the fundamentals and advanced techniques. Learn how to create precise bends, flanges, and cutouts, and optimize your.

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

solidworks sheet metal drawing pdf

Learn the essentials of sheet metal part design in SolidWorks with this comprehensive tutorial! This video is perfect for designers and engineers who want to.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hey Guys, Im pretty new in the sheet metal field. I have made a split on an original part and now trying to mirror what is left in respect to the split plane. . Mirror sheet metal parts. PR By Paul Rahmanian 08/18/09.

You can create notches across bends in flattened sheet metal parts. In manufacturing, bend notches help manufacturers determine where to put the press brake. You can use notch features on all bends so the bending operator can then use them to .Right click on a body and Export to DXF/DWG (or save as and change the file type to DXF or DWG). Save the initial file, but then in the DXF/DWG Output dialog change the export type to Sheet Metal and select all of the sheet metal bodies. Choose which entities you want to export and select "Separate Files" at the bottom.When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Search 'Mirroring Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS .

Hi u/Jadas922, . You are in "Flat Pattern" mode for sheet metal. Creating sheet metal features is not appropriate in that mode so they are grayed out. Clicking the button in the top right of the viewport will bring you back out of this to the folded state of the model.

I would like your opinion on sheet metal bodies in a multibody weldment part. Do you guys do that or do you create an assembly and pretend the parts are welded, when dealing with sheet metal parts. My current application involves a large sheet metal part with many bends accompanied by small welded plates for stronger tap locations.

What the guy did was make 2 parts that represent a sheet of metal that needs to bend in the middle, added a fillet on one edge on each part and then put them into a assembly and joined the fillets with a concentric mate . Started learning solid works two days ago for a new job. Been practicing making products that already exist.The fixed edge remains in place when the part is flattened. The name of the edge is displayed in the Fixed Face or Edge box. Set the Bend Radius. Select Ignore beveled faces to exclude chamfers from being converted into sheet metal bends.Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal . Sheet Metal Gauge is a setting SOLIDWORKS parts are assigned as soon as the first sheet metal feature is created. It's easy to create and manage multiple variations of similar parts or assemblies using configurations. We frequently configure the values of dimensions, the suppression state of features, and part materials. Sheet metal parts are no different, and we .

After you select the tab edge in a sheet metal part, SOLIDWORKS ® automatically selects a slot face that is normal to the edge to streamline the process. For non-sheet metal parts, you need to select the slot face. If you have nonintersecting regions of two bodies, the tab and slot feature applies only to the intersecting regions.In a sheet metal part, click Stamp (Sheet metal toolbar) or Insert > Sheet Metal > Stamp. . SOLIDWORKS 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. .

So I'm doing this as a sheet metal part, so that I can flatten my curved surfaces. Which is fine. I've used sheet metal parts to create corrugated boxes, etc. But I'm stuck here. The top of my pedal car is flat and tapers off in the back. That's all good. The bottom has the same taper but curves up towards the back. All good here too. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices for the first step: converting to sheet metal or building up from a base. Method 1 – Base Flange. For this option you start with the Sheet .When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and . How to Start a Sheet Metal Part in SolidWorksLET'S CONNECT!Google+ https://plus.google.com/+Cati1/posts Facebook https://www.facebook.com/CatiSolidWorks T.

metal roof sheet size

One problem I see with bent sheet metal parts is that you would need fourth dimension to fully describe the part as thickness would be the plate thickness. Think of a for example 500 mm wide, L-shape bend with 100 and 200mm long legs that is made out of 5mm steel plate.

Contents. General. Use the General screen in the Costing Template Editor to set the units and currency options.. Material. Use the Material screen in the Costing Template Editor to set the materials you need to manufacture the sheet metal part.. Thickness. Use the Thickness screen in the Costing Template Editor to set the thickness and cost values for each class and material .Normal sheet metal tools are for making straight bends. If you want to make a curved bend in the sheet metal add in, you can try using a the forming tool. You can probably get the desired shape with just a revolve extrude.

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

solidworks sheet metal download

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .Watch here, how to create a technological processing of sheet metal parts and assemblies with our SPI SheetMetal software. Get to know the SPI Component Manager and the new CAD-Viewer of SPI GmbH.

solidworks sheet metal basics

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. . This separation is typically negligible for any sheet metal part, but not for SOLIDWORKS. Figure 6 Figure 6a . 12 7) Avoid Self-Intersection with Edge-Flange .You all know that SOLIDWORKS will create a flat pattern with bend lines for sheet metal parts. The bend lines look like they are for a "folding" brake how do you tell SOLIDWORKS that the parts will be formed on a press with a V block and the adjust the bend lines accordingly? Share Sort by: Best. Open comment sort options .All of the answers so far are correct, I would use a Base Flange/Tab personally and make sure to choose merge so it just extends the face, but you can use any feature and as long as the geometry is correct it should flatten no problem.

sheet metal modeling in solidworks

High Quality Metal Turning & Machining, High Quality Precision Machined Parts, Quotes In Hours, Parts In Days

what is a sheet metal part in solid works|solidworks sheet metal basics