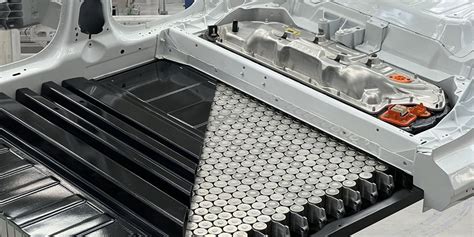

electric vehicle battery enclosure Keeping automotive batteries cool, clean and connected. Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any of our customers' EV needs, from hybrid to full battery . $22.00

0 · ev battery protection cover

1 · ev battery pack construction

2 · ev battery enclosure manufacturers

3 · ev battery casing material

4 · electric vehicle battery tray

5 · composite battery enclosure

6 · carbon fiber battery box

7 · automotive battery box design

Experience: R&S Services LLC

Roughly 80% of current EVs have an aluminum battery enclosure, but engineers are quick to note that the field is wide open for alternatives, based on vehicle type, duty cycles, .Novelis introduced new design innovations with the Second-Generation of its lightweight electric vehicle battery enclosure solution for the rapidly growing EV market. Learn more by .We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement .We help you to make the mobility of tomorrow even more efficient – with battery cases made from fiber composite materials. With significantly lower weight, they enable longer ranges and at the same time, meet other important .

Keeping automotive batteries cool, clean and connected. Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any of our customers' EV needs, from hybrid to full battery .Docol® EV Concept includes EV battery enclosures made from AHSS steel, optimizing floor cross beams to minimize crash intrusion on EV battery packs and more

Critical for contemporary battery enclosure strategy is design for disassembly, fire and thermal runaway protection, crash performance and recyclability. Designing a versatile, multi-material EV battery enclosure. Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material .

ev battery protection cover

Aluminum extrusions produce high performance electric vehicle battery systems and packaging. Learn why aluminum extrusions are effective for robust battery box or housing design.Magna began production on two complete battery enclosure systems for fully electric vehicles in North America in 2022. Our first battery enclosure was produced in Europe in 2011 for a hybrid electric vehicle. Magna offers the . Roughly 80% of current EVs have an aluminum battery enclosure, but engineers are quick to note that the field is wide open for alternatives, based on vehicle type, duty cycles, volumes, and cost.

Novelis introduced new design innovations with the Second-Generation of its lightweight electric vehicle battery enclosure solution for the rapidly growing EV market. Learn more by downloading the product Fact Sheet.

We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement system that .We help you to make the mobility of tomorrow even more efficient – with battery cases made from fiber composite materials. With significantly lower weight, they enable longer ranges and at the same time, meet other important requirements for safety, economy and thermal management better than conventional materials.Keeping automotive batteries cool, clean and connected. Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any of our customers' EV needs, from hybrid to full battery electric vehicles.Docol® EV Concept includes EV battery enclosures made from AHSS steel, optimizing floor cross beams to minimize crash intrusion on EV battery packs and more

Critical for contemporary battery enclosure strategy is design for disassembly, fire and thermal runaway protection, crash performance and recyclability. Designing a versatile, multi-material EV battery enclosure. Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.Aluminum extrusions produce high performance electric vehicle battery systems and packaging. Learn why aluminum extrusions are effective for robust battery box or housing design.

Magna began production on two complete battery enclosure systems for fully electric vehicles in North America in 2022. Our first battery enclosure was produced in Europe in 2011 for a hybrid electric vehicle. Magna offers the complete array of battery enclosure production and . Roughly 80% of current EVs have an aluminum battery enclosure, but engineers are quick to note that the field is wide open for alternatives, based on vehicle type, duty cycles, volumes, and cost.Novelis introduced new design innovations with the Second-Generation of its lightweight electric vehicle battery enclosure solution for the rapidly growing EV market. Learn more by downloading the product Fact Sheet.

We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement system that .

We help you to make the mobility of tomorrow even more efficient – with battery cases made from fiber composite materials. With significantly lower weight, they enable longer ranges and at the same time, meet other important requirements for safety, economy and thermal management better than conventional materials.

Keeping automotive batteries cool, clean and connected. Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any of our customers' EV needs, from hybrid to full battery electric vehicles.Docol® EV Concept includes EV battery enclosures made from AHSS steel, optimizing floor cross beams to minimize crash intrusion on EV battery packs and more Critical for contemporary battery enclosure strategy is design for disassembly, fire and thermal runaway protection, crash performance and recyclability.

Designing a versatile, multi-material EV battery enclosure. Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.Aluminum extrusions produce high performance electric vehicle battery systems and packaging. Learn why aluminum extrusions are effective for robust battery box or housing design.

ev battery pack construction

metal fabrication needs in portland oregon

ev battery enclosure manufacturers

An apprenticeship test (or pre-apprenticeship test) is designed to assess candidates applying for an apprenticeship in one of the labor unions across the U.S. and Canada. Common examples are the IBEW Test (electricians), the EIAT (elevator mechanics), and .

electric vehicle battery enclosure|ev battery pack construction