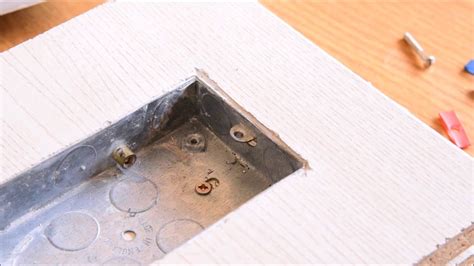

electrical back box screw thread Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new . my son just bought a factory Savage GRS rifle in 6 mm creedmoor that blows factory primers or even reduced reloaded ammo, barrel issues as I checked headspace with .

0 · youtube back box screw thread

1 · stripped metal back box thread

2 · metal back box screw thread repair

3 · metal back box screw repair

4 · electrical back box screw thread repair

5 · back box thread repair

6 · back box stripped thread repair

7 · back box screw thread fixer

Yes, you can, but it’s not always necessary. If you prefer the additional height or have a traditional innerspring mattress, a box spring can be used with a metal bed frame. Ensure the frame is sturdy enough to hold the .

youtube back box screw thread

If neither of those work drill through the back of the box and tap a new 3.5mm thread. Use a longer screw to secure the accessory.

stripped metal back box thread

If it's a really old box likely it was tapped with imperial threads. You can buy a . Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new .

A demo on how to use the BBS1 Backbox Saver, from RTP Inventions LtdBack Box Saver saves time and money, providing a new secure fixing if your electrical back box has a broken screw thread. Buy Designed for back boxes in the UK. With some you can insert new screw plates that hook inside the back box. Another trick is put a blank plate on front and insert a long thin rod with a bit of paint on back and push .

It’s quite common for the lug in an electrical back box to become stripped, this can easily be rectified by using a socket re-threading tool like this- http:.

REBBAL (Replacement Electrical Back Box Attachment Lug) gives the movement and adjustment of the original sliding lug, so it can even be used to replace the fixed side if movement is needed to square up the front . The thread pitch must be -32 or finer (which in practice means -32). This is necessary for ground to be passed through the screw threads, if you are using the mounting screws to carry ground. All "green ground screws" .

metal back box screw thread repair

metal back box screw repair

adrian steel tool box for sale

If neither of those work drill through the back of the box and tap a new 3.5mm thread. Use a longer screw to secure the accessory.

Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new hole, and re-mount the outlet. Replace the box. If it were me, I would do number 3. Obviously, make sure the electricity to the outlet is turned off before doing any work. Edit 1 : OP says the box .

A demo on how to use the BBS1 Backbox Saver, from RTP Inventions LtdBack Box Saver saves time and money, providing a new secure fixing if your electrical back box has a broken screw thread. Buy Designed for back boxes in the UK.

With some you can insert new screw plates that hook inside the back box. Another trick is put a blank plate on front and insert a long thin rod with a bit of paint on back and push until you reach the rear of box.It’s quite common for the lug in an electrical back box to become stripped, this can easily be rectified by using a socket re-threading tool like this- http:.

REBBAL (Replacement Electrical Back Box Attachment Lug) gives the movement and adjustment of the original sliding lug, so it can even be used to replace the fixed side if movement is needed to square up the front plate because the back box isn’t level. The thread pitch must be -32 or finer (which in practice means -32). This is necessary for ground to be passed through the screw threads, if you are using the mounting screws to carry ground. All "green ground screws" intended for . On normal electrical boxes, screws are usually 6-32. this being a bit light for a fan, also expect 8-32 or 10-32. Ground screws are 10-32. It's not a coincidence that they are -32, given the thickness of standard metal junction boxes, that is the minimum number of threads to properly engage. Never use sheetmetal screws.

If it's a really old box likely it was tapped with imperial threads. You can buy a 3.5mm retapping tool from most electrical wholesalers, same size as a small screwdriver. Try using your M3.5 retapping tool on the lugs. If neither of those work drill through the back of the box and tap a new 3.5mm thread. Use a longer screw to secure the accessory. Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new hole, and re-mount the outlet. Replace the box. If it were me, I would do number 3. Obviously, make sure the electricity to the outlet is turned off before doing any work. Edit 1 : OP says the box .

A demo on how to use the BBS1 Backbox Saver, from RTP Inventions LtdBack Box Saver saves time and money, providing a new secure fixing if your electrical back box has a broken screw thread. Buy Designed for back boxes in the UK. With some you can insert new screw plates that hook inside the back box. Another trick is put a blank plate on front and insert a long thin rod with a bit of paint on back and push until you reach the rear of box.

It’s quite common for the lug in an electrical back box to become stripped, this can easily be rectified by using a socket re-threading tool like this- http:.

REBBAL (Replacement Electrical Back Box Attachment Lug) gives the movement and adjustment of the original sliding lug, so it can even be used to replace the fixed side if movement is needed to square up the front plate because the back box isn’t level.

The thread pitch must be -32 or finer (which in practice means -32). This is necessary for ground to be passed through the screw threads, if you are using the mounting screws to carry ground. All "green ground screws" intended for . On normal electrical boxes, screws are usually 6-32. this being a bit light for a fan, also expect 8-32 or 10-32. Ground screws are 10-32. It's not a coincidence that they are -32, given the thickness of standard metal junction boxes, that is the minimum number of threads to properly engage. Never use sheetmetal screws.

electrical back box screw thread repair

back box thread repair

Electrical conduits are essential for a wiring job and depend on the wiring needs. You can choose from rigid metal, intermediate metal, and flexible metal conduits, electrical metallic and non-metallic tubing, liquid-tight flexible .

electrical back box screw thread|metal back box screw thread repair