220 line junction box crimp ring It would appear that the main issue with my plan is in the use of junction boxes with screw terminals, and the need to be able to inspect them; Could I crimp or solder the .

LOCATOR Attachment System is the most globally recognized and trusted brand for overdenture restorations. Combining innovative patented technology with availability in more than 280 implant connections has propelled it to be the preferred choice of clinicians with more than 4 million satisfied patients.

0 · crimping wires with ring connectors

1 · crimped wire connections

2 · crimped wire connection restrictions

3 · crimped on ring outlets

4 · crimped on ring connections

5 · crimped aluminum connections

6 · crimp ring wire under screw

7 · crimp ring wire

Los brackets de zafiro son ortodoncias cuyo material principal es el zafiro. Se caracterizan por ser discretos y permanecer inmutables durante el tiempo que dure el tratamiento, es decir, que no cambian ni su aspecto ni su forma.

crimping wires with ring connectors

steel square box section sizes

crimped wire connections

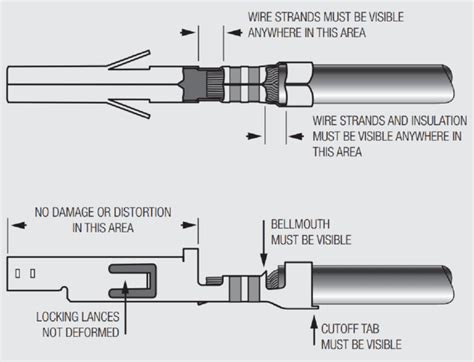

Make sure you're using the proper sized connectors, and you shouldn't have a problem. The primary issue with crimp terminals is using a . I will be wiring some 220 and 110 outlets in my garage, running stranded THHN through EMT conduit. I plan to put crimp connectors at the ends of the wires. Should I use . Learn how to securely connect wires in a junction box for safe electrical installations. Follow step-by-step instructions for twisting, securing, and troubleshooting wire .

The other is to crimp a ring lug to the end of the wire which allows you to remove the screw from the receptacle, put it through the hole in the lug, and then tighten it down. . The splices must also be inside a junction box. Crimp caps are an accepted method of connection for copper wiring. I wouldn't use butt crimps although they are also . It would appear that the main issue with my plan is in the use of junction boxes with screw terminals, and the need to be able to inspect them; Could I crimp or solder the .

What happens to the boat dock end? Anyway, if it is a low-lying JB as described above, you can resplice the wires using butt crimps and heat-shrink tubing. This is if you have . #1 they may not be UL-Listed for use with AC wiring. #2 you must have 6" of free wire length inside a junction box and 3" beyond the surface of the wall as well, and if you don't .

steel sideboard cabinet

Can I splice the existing 220 line to another 10 feet of cable to make it reach? Do I need a special junction box for this or can I use the same ones I use with 110? The wires are . Thinking I'll crimp a 8 gauge ring terminal on the wire and out it under the screw on the receptacle. The big box stores sell an adapter. One side plugs into the existing 220 outlet. . Make sure you're using the proper sized connectors, and you shouldn't have a problem. The primary issue with crimp terminals is using a GOOD crimper with the proper size dies for the connector and wire size/number - otherwise you . I was wondering, could I use a crimp ring connector under the ground screw? That would remove the wire between the wago and the box and the wago itself. It would then be very easy to tuck all the ground wires nicely in the box.

For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires. I will be wiring some 220 and 110 outlets in my garage, running stranded THHN through EMT conduit. I plan to put crimp connectors at the ends of the wires. Should I use spade/fork connectors or ring connectors to connect the wire to the outlets? Learn how to securely connect wires in a junction box for safe electrical installations. Follow step-by-step instructions for twisting, securing, and troubleshooting wire connections. Ensure compliance with electrical codes.

The other is to crimp a ring lug to the end of the wire which allows you to remove the screw from the receptacle, put it through the hole in the lug, and then tighten it down. Using a ring lug allows you to ensure a good tight connection!

The splices must also be inside a junction box. Crimp caps are an accepted method of connection for copper wiring. I wouldn't use butt crimps although they are also approved.

It would appear that the main issue with my plan is in the use of junction boxes with screw terminals, and the need to be able to inspect them; Could I crimp or solder the connections, insulating the join appropriately?

Yes crimped junctions should be within an enclosure and often there is a good enclosure nearby - the back box with the socket fixed to it!

You can run a ring cable out from the existing socket point backing box, then on to the next socket, and so on, until you reach the last one, at which point you re-join to the ring, and you should use a MK 30Amp Junction Block that has been made specially to . Make sure you're using the proper sized connectors, and you shouldn't have a problem. The primary issue with crimp terminals is using a GOOD crimper with the proper size dies for the connector and wire size/number - otherwise you . I was wondering, could I use a crimp ring connector under the ground screw? That would remove the wire between the wago and the box and the wago itself. It would then be very easy to tuck all the ground wires nicely in the box. For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), then stick a 2-gang "mud ring" on it, then stick plain 120V receptacles or switches there, fed by totally separate 120V / #12 wires.

I will be wiring some 220 and 110 outlets in my garage, running stranded THHN through EMT conduit. I plan to put crimp connectors at the ends of the wires. Should I use spade/fork connectors or ring connectors to connect the wire to the outlets?

Learn how to securely connect wires in a junction box for safe electrical installations. Follow step-by-step instructions for twisting, securing, and troubleshooting wire connections. Ensure compliance with electrical codes. The other is to crimp a ring lug to the end of the wire which allows you to remove the screw from the receptacle, put it through the hole in the lug, and then tighten it down. Using a ring lug allows you to ensure a good tight connection! The splices must also be inside a junction box. Crimp caps are an accepted method of connection for copper wiring. I wouldn't use butt crimps although they are also approved.

It would appear that the main issue with my plan is in the use of junction boxes with screw terminals, and the need to be able to inspect them; Could I crimp or solder the connections, insulating the join appropriately? Yes crimped junctions should be within an enclosure and often there is a good enclosure nearby - the back box with the socket fixed to it!

CNC Machining is our specialty. Simple or complex, we take on projects with full commitment. Zero Hour Parts has many CNC machines ready to take on your critical parts including 5 axis milling and 4 axis live turning. EDM, grinding, heat treating, anodize, chem film, and many more.

220 line junction box crimp ring|crimped aluminum connections