defects in drawn sheet metal parts This article provides an overview of these common defects, their causes, and possible preventive measures, finishing with a look at how Prolean’s Sheet Metal Deep-drawing Services help ensure a defect-free deep-drawing . Peruse our collection of Metal and Copper Liners, featuring galvanized metal and .

0 · wrinkle defect in sheet metal

1 · types of sheet metal defects

2 · steel lamination defect pictures

3 · sheet metal rolling defects

4 · sheet metal defects pdf

5 · scoring marks in sheet metal

6 · defects in sheet metal operation

7 · defects in sheet metal forming

Double acting hydraulic cutting system for high tensile wire on machines larger than 4mm capacity; One keystroke transition between Metric and English units of measure; Optional video camera for machine monitoring or videoconferencing; Merge individual part programs for production of complete assemblies or program to make alternating parts

wrinkle defect in sheet metal

4. Stamping Defects: Cracks, Wrinkles, and Tool Marks Defects and Causes. Cracks: Material failure during high-force stamping operations. Wrinkles: Surface distortions on deep-drawn or stretched components due to improper blank holding. Tool Marks: Scratches or indentations . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers . This article provides an overview of these common defects, their causes, and possible preventive measures, finishing with a look at how Prolean’s Sheet Metal Deep-drawing Services help ensure a defect-free deep-drawing . In this paper, a state of art related to the image classification with CNNs in the field of quality assurance of sheet metal components is presented and methods are described, how .

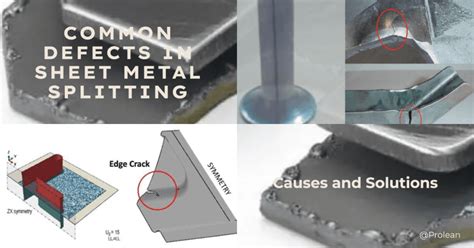

Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are . Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, . Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.

From this perspective, this paper presents an application of ML methods in order to classify defective deep drawn parts. It proposes a methodical approach which includes not only the .Wrinkles, splits, and springback are the three most common defects encountered during sheet metal stamping. Generally, if experiencing wrinkles during production, this could mean the wrong process was chosen to manufacture .4. Stamping Defects: Cracks, Wrinkles, and Tool Marks Defects and Causes. Cracks: Material failure during high-force stamping operations. Wrinkles: Surface distortions on deep-drawn or stretched components due to improper blank holding. Tool Marks: Scratches or indentations from worn or misaligned dies. Solutions. Choose high-ductility materials for complex stamping . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers to an uneven height around the rim of the drawn part. The main reason is neglecting the work and die materials compatibility. 5 Tips to Avoid Typical Sheet Metal Defects

Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process. This article provides an overview of these common defects, their causes, and possible preventive measures, finishing with a look at how Prolean’s Sheet Metal Deep-drawing Services help ensure a defect-free deep-drawing process. 1.1 1. Understanding the Process. 1.2 2. Deep-Drawing Process Parameters. 2 What Are the Root Causes of These Defects? In this paper, a state of art related to the image classification with CNNs in the field of quality assurance of sheet metal components is presented and methods are described, how a model can be built and optimized in order to successfully classify defective deep drawn parts.

Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are being pushed past their workability limits, to the point the sheet metal is beginning to thin. Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, cracking, and surface imperfections, manufacturers can take proactive steps to prevent these problems.

Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.

From this perspective, this paper presents an application of ML methods in order to classify defective deep drawn parts. It proposes a methodical approach which includes not only the data acquisition using a low-cost equipment, but also the data pre-processing as well as the setup and training of the ML model.

Wrinkles, splits, and springback are the three most common defects encountered during sheet metal stamping. Generally, if experiencing wrinkles during production, this could mean the wrong process was chosen to manufacture the part or a key process parameter (such as binder force) could be incorrect.

4. Stamping Defects: Cracks, Wrinkles, and Tool Marks Defects and Causes. Cracks: Material failure during high-force stamping operations. Wrinkles: Surface distortions on deep-drawn or stretched components due to improper blank holding. Tool Marks: Scratches or indentations from worn or misaligned dies. Solutions. Choose high-ductility materials for complex stamping . Sheet Metal Deep-Drawing Defects. Earing, wrinkling, and material tearing are the major sheet metal defects associated with the deep-drawing process. The earring defect refers to an uneven height around the rim of the drawn part. The main reason is neglecting the work and die materials compatibility. 5 Tips to Avoid Typical Sheet Metal Defects Sheet metal defects affect the appearance, function or structural integrity of the sheet metal. Learn the defects and avoid them in the sheet metal process. This article provides an overview of these common defects, their causes, and possible preventive measures, finishing with a look at how Prolean’s Sheet Metal Deep-drawing Services help ensure a defect-free deep-drawing process. 1.1 1. Understanding the Process. 1.2 2. Deep-Drawing Process Parameters. 2 What Are the Root Causes of These Defects?

In this paper, a state of art related to the image classification with CNNs in the field of quality assurance of sheet metal components is presented and methods are described, how a model can be built and optimized in order to successfully classify defective deep drawn parts.

types of sheet metal defects

Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits. A series of wrinkles is growing and propagating. The layers of metal are being pushed past their workability limits, to the point the sheet metal is beginning to thin. Defects in sheet metal processing can lead to costly errors and compromise the quality of your final product. However, by identifying common issues such as warping, cracking, and surface imperfections, manufacturers can take proactive steps to prevent these problems.

Part II of this series about sheet metal defects focuses on the common problems that can be caused during various stages of the material's production.From this perspective, this paper presents an application of ML methods in order to classify defective deep drawn parts. It proposes a methodical approach which includes not only the data acquisition using a low-cost equipment, but also the data pre-processing as well as the setup and training of the ML model.

junction box manufacturing process

10 Piece Christmas Cookie Cutters, 3d Raised Design Gingerbread Cookie Stamps, Cookie Cutter Set suitable for Frosting Decoration, Mini Pie Molds, Apple Pie Pastry Biscuit Cutter .

defects in drawn sheet metal parts|sheet metal defects pdf