sheet metal bend Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal . Precision CNC Machining Parts Service & Custom CNC Machined Parts Manufacturer. Bergek CNC is good at making prototypes, small-batch, or mass-production customized CNC machined parts. Come to get instant quotes on metal and plastic machined parts.

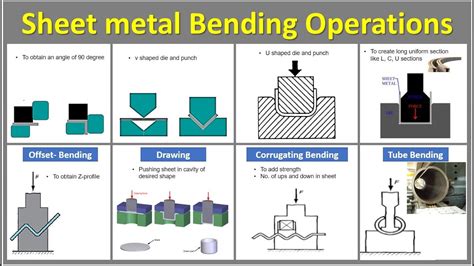

0 · types of sheet metal bends

1 · types of sheet metal benders

2 · sheet metal bending dies

3 · sheet metal bend tolerance chart

4 · sheet metal bend allowance chart

5 · maximum thickness sheet metal bending

6 · bend sheet metal at home

7 · bend allowance in sheet metal

Order high precision CNC machining parts online with flexibility and certainty. ISO 9001 and 13485 Certified! Access a wide range of precision machining capabilities through our global network of manufacturing partners. 3, 4 and 5 axis CNC machining for both low and high complexity milling parts.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a . Sheet Metal Bending Calculator. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal .

Navigating the world of sheet metal bending might seem daunting at first, especially when transitioning from 2D designs to 3D parts. However, understanding and avoiding common pitfalls can make the process smooth .The Bend-Tech Sheet Metal Designer (SM) is a simple and powerful design software that is geared toward the hobbyist, school, prototype shop, maintenance facility, or performance shop. You will no longer need to spend your money on expensive, high-end solid modeling CAD systems to be able to design sheet metal parts. Bend-Tech SM is also very .Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Bending can improve a part’s structural integrity by increasing part stiffness, redistributing stress within a part, and help . Bend Allowance Chart. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials.

types of sheet metal bends

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . Forces needed to bend sheet metal . Bending . Stress distribution through the thickness of the part s s y Y Y -Y Y Elastic Elastic-plastic Fully Plastic Moment, M = Y (b h/2) h/2 = Ybh2/4 You can perform various intricate sheet metal operations, such as reinforcing floor channels, corrugated pickup truck beds, truck headboards, metal mudguards, etc., all achievable using this segmented sheet metal brake. Heavy-Duty Metal Sheet Brake: The maximum bending width of the box and pan brake is 24 inches/610 millimeters.

About this item. Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a .The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out.Bending A chimney starter, a sample product of bending. Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. [1] Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses.Typical products that are made like this are . When bending sheet metal, Inventor states the flange as being bent up when inserting bend notes on drawings but the bend line is actually bent down as would be the case on the press brake as the knife presses into the vee. Does anyone know of the BS or ISO standard drawing principle for this notatio.

Bend features can join sheet metal faces that do not touch. When you select edges on sheet metal features, you add material to the model using the bend radius and material thickness defined by the sheet metal style. Faces extend in compliance with your default (or selected) bend radius. If the faces are parallel, but not coplanar, you can add a . How sheet metal bends, k factor, bend allowance explained and more. This video includes drawings, animations, formulas and press brake bends.More On K Facto. When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Tab - Add a tab .

The Klein Tools Offset Hand Seamer makes working in confined spaces easy with the compound-leverage mechanism and convenient self-opening latch. The 3 inch steel jaw is notched in 1/4-Inch increments for accurate sheet metal bending measurements. Comfortable, contoured grips cover durable, all-steel construction for long life and durability. Sheet metal bending with a press brake works by aligning and holding the metal to be bent in the press brake tool. Once it is aligned, the press can move down and exert a force onto the metal, forming it into a new shape by producing angles. Press brakes can exert forces well in excess of 100 tons to bend steel upwards of 3 mm thick.

Can they calculate the metal deformation across the bend with that kind of accuracy? . I'm used to +/-.030" as the standard tolerance for bent sheet metal parts without really thinking about it. Tighter can be achieved, so +/-.015" seems reasonable if that's what you need. If small parts are coming back +/-.125" or more, then that is just wrong.

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.Powerful Bending Ability. The mini sheet metal bending brake is available in bending widths up to 18 inches and in bending thicknesses up to 20 Ga. With a solid, heavy-duty construction and steel-welded body, it is easy to bend stainless steel, copper, aluminum, iron, galvanized steel, and other sheet metals. Flexibility and VersatilitySheet Metal Folding Tool: Hurricane 24" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together Two Folding Depths: Creates 3/8" and 1" depth folding in ductwork

Sheet Metal Bend Radius Guidelines Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical enclosures. These and countless other sheet metal components might seem fairly simple to manufacture, but achieving part accuracy involves some fairly complex bending calculations. That’s . Hi, Our team uses sheet metal bending about 75% of the time I would like to increase our productivity by using this application for certain projects. It seems to be missing metal bending, mating, sub assemblies and other things that software such as SolidWorks has, what is the goal and timeline for these types of features. .Sheet metal bend line notes allow: Editing content; Modifying default format. Edit install_dir\lang\language\bendnoteformat.txt; Maintaining associative capabilities. Change the bend angle, bend direction, or bend radius, and the notes update in the drawing. Positioning notes. Change the display position of bend notes.Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .

Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a .

types of sheet metal benders

sheet metal bending dies

sheet metal bend tolerance chart

how to open an outside electrical box

CNC lathes produce parts by feeding a cutting tool into rotating material. eMachineShop offers a cost-effective turning services whether you need a single part, batch of prototypes, or a production order. 50+ Materials. FREE Shipping in the USA. 100% .

sheet metal bend|types of sheet metal benders