metal fabrication safety tips Keeping your prefab shop clean and orderly is important for several reasons that pertain to safety. When shops are not clean and orderly there are an inordinate number of slips, trips and falls, . Study with Quizlet and memorize flashcards containing terms like For a rivet joint to develop its required strength, no rivet should be installed with its center nearer to the edge of a sheet than .

0 · sheet metal fabrication safety

1 · safety tips for steel

2 · safety of metal fabrication

3 · metal fabrication safety standards

4 · metal fabrication safety requirements

5 · metal fabrication safety hazards

6 · metal fabrication safety clothing

7 · fabrication shop safety topics

An uncommon component that can be recycled into Metal Fragments and High Quality Metal, or used in the crafting of Heavy Plate armor pieces. It can be found in crates and barrels.

Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal.

Here are my top six safety tips to keep in mind during steel fabrication and erection: 1. Identify Workplace Risks Risk assessment is considered the first critical step when it comes to .Keeping your prefab shop clean and orderly is important for several reasons that pertain to safety. When shops are not clean and orderly there are an inordinate number of slips, trips and falls, . Prioritizing worker safety and well-being in metal fabrication is a commitment requiring continuous effort. By recognizing and assessing risks, providing proper training, ensuring PPE usage, organizing the workspace, .What are some metal fabrication safety tips? Wear the proper protective gear. Make sure clothes are tight-fitting. Conduct regular equipment inspection. Keep work area organized. Implement safety rules. Train the workforce. In any .

Working in the metal fabrication industry can be dangerous without the correct safety procedures. Learn how to improve safety for your employees today.

sheet metal fabrication safety

safety tips for steel

Discover essential safety measures for your steel fabrication project. From training to equipment inspection, ensure worker safety and project success. Why is metal fabrication safety so important? What can shop owners and supervisors do to ensure their factory floors are as safe as possible? Common safety problems Steel fabrication safety tips play a crucial role in mitigating potential hazards and accidents. Let’s delve into the top 10 safety measures you should implement throughout your steel fabrication endeavor. . workers in .Safety in metal fabrication shops begins by making employee health and well-being a priority. According to the U.S. Bureau of Labor Statistics, more than 16,000 workers are seriously hurt and 50 are killed every year in fabricated .

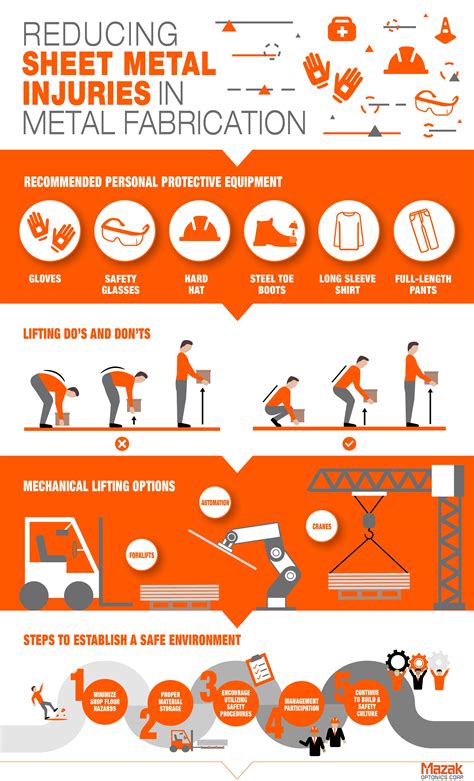

Safety must always come first in metal fabrication to safeguard employees and avoid mishaps. This entails enforcing safety regulations, such as donning the proper personal protective equipment (PPE), keeping the workplace tidy and . 4 Tips For Metal Fabrication Safety – Don’t Fall Short on This! Manufacturing, construction, and the automobile industry are just a few that depend heavily on metal fabrication. Although it has many advantages, it also puts workers at risk for serious injuries like cuts and burns. Therefore, it is crucial to place a high priority on metal . Personal. Personal safety covers all of the personal protective equipment (PPE). When reviewing PPE, start with the head and work down. Proper PPE required for welding includes a welding cap; safety glasses; welding hood with proper shade lens; clear face mask; cotton, wool, or leather welding jacket; leather welding gloves designed for the process you .

Safety is of utmost importance in metal shops to protect workers from potential hazards and ensure a secure working environment. One essential aspect of maintaining safety is the proper use of . Metal fabrication involves the use of heavy machinery and hazardous materials, making it critical for facilities to prioritize safety. Workers in a fabrication shop can put themselves at risk of injury when they neglect safe practices. Understanding common metalworking safety tips can help your staff protect themselves while working. Consider .

safety of metal fabrication

When using extension cords, keep the following safety tips in mind: . Welders frequently use shears and punches in the fabrication of metal for welding. These machines can be operated either by hand or by powerful motors. Hand-operated equipment is usually limited to thin sheet stock or small bar stock. Powered equipment can be used on a .Ultimately, the success of a safety program in the sheet metal fabrication industry depends on the active engagement and commitment of all stakeholders, from management to frontline workers. By fostering a safety-focused culture that prioritizes the well-being of employees, businesses can create an environment where safety is not just a .

Toolbox Safety Talks for Fabrication Shops Mechanical Contractors Association of America, Inc. 1385 Piccard Drive Rockville, MD 20850 800-556-3653 • www.mcaa.org . Title: Toolbox Safety Talks for Fabrication Shops Author: MCAA Subject: . Safety is not just a protocol but a deeply ingrained ethos at Har-Noy Metal Fabricators in Olathe, KS. Our unwavering commitment to fostering a culture of safety, coupled with rigorous training, state-of-the-art equipment maintenance, and proactive measures, ensures that our employees work in an environment where their well-being is the top priority. We . The following are some safety tips every metal fabricator should keep in mind. . Electrical Safety. Metal fabrication often involves working with electrical equipment. Always follow electrical .Here are my top six safety tips to keep in mind during steel fabrication and erection: 1. Identify Workplace Risks Risk assessment is considered the first critical step when it . To ensure that metal fabrication shops and job sites are safe, regular inspections and .

mobile metal fabrication hilliard ohio

A safety-first operation will also make OSHA compliance front and center in their quality control program. 5: Implementing a Safety-Savvy Quality Control Program for OSHA-Compliant Fabrication. Experienced metal fabricators make safety best practices an integral part of their documented quality control (QC) program. As part of the QC program at . Metal fabrication tips and tricks are the little things that make completing a process either easier or substantially improve the quality of the end result. . Proper protective gear is essential when working with softer metals . The following tips will help sheet metal fabrication workshops strike a balance between safety and productivity. Strict Adherence to OSHA Guidelines : Occupational Safety and Health Administration (OSHA) is the agency under the United States Department of Labor, which works towards assuring healthful and safe working conditions for men and women. As a fundamental tool in sheet metal fabrication, the press brake plays a pivotal role in shaping and forming metal sheets. However, its operation involves inherent risks that necessitate stringent safety measures to safeguard operators and prevent accidents. . By adhering to these essential safety tips, operators can minimize risks and .

4: Build a Reputation for Fabrication Safety. As noted earlier, reducing employee turnover is tied to consistent quality control and fabrication safety. When a metal fabricator earns the reputation as a safe place to work, it attracts highly trained job applicants and prevents skilled labor from seeking greener employment pastures. Metal Fabrication Workshop Safety Tips. The following tips can help to minimize the risk of injuries and ensure your business complies with OSHA requirements for fabrication shops: Set a tone for safety at the top: If your company’s leadership doesn’t demonstrate a “safety-first” mindset, you can’t expect your workforce to make safety . When it comes to industrial metal fabrication, there are several key strategies you should focus on to elevate your projects. Start by optimizing your material selection, taking into account factors such as durability, cost, and availability. Next, prioritize precision cutting techniques like laser cutting to enhance accuracy and minimize waste. Ensuring proper .

First, let’s cover the most common safety concerns within the metal fabrication industry, their costs, and an umbrella method of solutions. 1. Machine Guarding. According to OSHA reports, guarding and the proper usage of machinery cost the metal fabrication industry nearly million. Moving machinery creates the potential for crushed fingers .Following these safety measures can protect workers and promote a culture of safety in metal shop environments. At Jersola Engineering, we prioritize safety protocols as they affect all aspects of our business. Here are some safety tips that every metal fabricator should remember: 1. Use Personal Protective Equipment properly.

Custom Metal Fabrication Safety Precautions and Tips . Metal fabrication is an integral part of many different industries with custom metal fabrication serving an even more niche role yet still widely important. It is a process that involves the use of raw materials to create structures and components. However, your metal fabrication workshop . Warning others and posting safety notices are simple yet effective welding safety tips that help keep the entire job site safe. Clear signage around welding areas can alert everyone to welding hazards like sparks, fumes, or hot surfaces. As shown in the image above, visible and updated signs remind people to stay alert and maintain a safe distance. Ensuring safety in home metal fabrication is crucial for both beginners and experienced fabricators. By focusing on wearing proper protective gear, maintaining an organized and safe workspace, using the right tools, and following set safety procedures, you can minimize risks and enjoy a productive and enjoyable fabrication experience.Sheet metal fabrication involves cutting, bending, and shaping metal sheets. These processes can pose several risks, such as: Cuts and Lacerations: Sharp edges of sheet metal can cause serious cuts.. Eye Injuries: Flying metal particles can injure the eyes.. Burns: Heat generated during welding or cutting can cause burns.. Crushing Injuries: Heavy metal sheets can cause .

It helps to understand the most common hazards and then take the appropriate steps to keep safe. Below, read the top five safety tips for safe metal fabrication. What are the Dangers? Every metal fabrication task is different, but there are certain hazards common to the field, at large. Here are a few of the most common dangers: - Musculoskeletal.

metal fabrication safety standards

In this article, we will go over 17 different types of silk fabric and their characteristics. We will cover what each type of silk is best suited for and the highest quality silk you can find.

metal fabrication safety tips|metal fabrication safety hazards