sheet metal hole distance from edge Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . $199.99

0 · sheet metal rib design guidelines

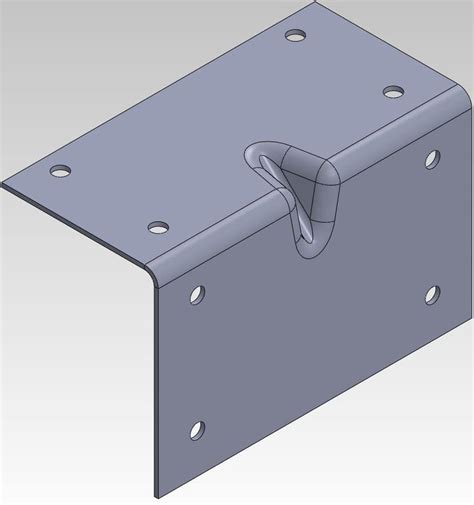

1 · sheet metal gusset design guidelines

2 · sheet metal extruded hole design

3 · sheet metal dimensioning guidelines

4 · sheet metal design guidelines pdf

5 · sheet metal bending guidelines

6 · sheet metal bending design guidelines

7 · minimum flange length sheet metal

This shallow box comes with 1/2 and 5/8 inch drywall thickness adapters, a cord grip insert to hold the wire in place and the screws you will .

Hole/Slot Distance from Bend Edge. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.K Factor in sheet metal bending is a constant used to calculate sheet metal .

electrical junction box ground wire

Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom sheet metal fabrication design has semi-pierced . If holes must be near the edge, they should still be at least the distance equal to the sheet thickness (T) from the edge and preferably between 1.5T and 2T from the edge. Distances between.

Minimum Distance from extruded hole to part edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to .

electrical junction box exterior above ground

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material . To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple . Calculating Minimum Edge Distance and Bend Distance. Selecting a hole position too close to a part’s edge or bend radius can significantly impact the performance of the final product. Fortunately, calculating a better hole .Minimum Distance from Extruded Hole to Part Edge. Extruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. If an extruded hole is too close to the part edge, it can lead to .

electrical junction box images

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. .

Information on the necessary edge distances in wooden components can be found, for example, in DIN EN 1995-1-1: 2010-12 (Eurocode 5). There are various parameters to consider, which have an influence on the .Prior to squeezing the trigger on an air drill, the chuck should be turned by hand at the point of drilling the material to make a slight indentation.Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Hole Diameters. Hole Spacing. Bend .We offer welded assemblies, standard mill, edge breaking, and orbital-sanded surface finishes along with a number of additional sheet metal finishing options:. Seam, tack, and stitch welding Hardware insertion and riveting: Standard PEM sheet metal hardware; Powder coating: A variety of powder coat paint colors available in textured and non-textured finish, including RAL colors.

Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material thickness and the specific features involved, aiming for a balanced and efficient design. . there needs to be a minimum distance from a threaded .

If holes must be near the edge, they should still be at least the distance equal to the sheet thickness (T) from the edge and preferably between 1.5T and 2T from the edge.

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal. t = Sheet metal thickness

sheet metal rib design guidelines

sheet metal gusset design guidelines

45° gussets shouldn’t be designed to be more than 4 times material thickness on their flat edge; For holes, the distance between the gusset and the hole’s edge should be at least 8 times material thickness. Hems. Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch.Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Related concepts. Hole Diameters .

Sheet Metal Rules: Hole Diameters: Hole-to-Edge Distances: Hole Spacing: Bend Radii: Standard Hole Sizes: Injection Molding Rules: Configuring Rules: Validating Parts: . set Simple Hole-Part Edge Distance to Thickness Ratio and Countersink-Part Edge Distance to Thickness Ratio. Parent topicSheet Metal Rules. Hole Diameters. Hole Spacing. Bend .

sheet metal extruded hole design

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. From consumer electronics, to medical devices, and obviously automotive - sheet metal part design plays a role in most modern products.PEM® REF/ C/L TO EDGE APRIL 2019 SUBJECT: MINIMUM DISTANCE HOLE C/L TO EDGE The term “minimum distance hole-centerline-to-edge” is defined as the minimum distance the mounting hole centerline may be to one edge of a panel to still allow the proper clinching of a fastener into the sheet. When a fastener is close to more than one edge, the .Lay out and prick punch all the holes, insert the proper size of punch or die into the hand lever punch, place the sheet metal pattern on the workbench with the holes to be punched extending 1" to 2" beyond the edge of the workbench use bench weights, place the centering point of the metal of the male punch in the center of the marked hole .

Or just design it so the holes are the appropriate distance from the bend radius . Unfortunately many engineers aren't sheet metal experts. In CAD you can draw pretty much anything. In the real world there are constraints. . I observe there will still have distortion on holes edge but compare to normal V-die the deformed edge is press into .

what drill bit is used to cut holes for 1/8 diameter rivet . What should not be used when doing a layout on sheet metal aluminum? A scribe. What is used as an aid when doing layout work with pencil? . The Structural Repair Manual. What are the limits for edge distance with a MS20426AD4-5 rivet?.25" min and .5" max. What are the safety . Tapped hole diameter/2 + the minimum tap hole-to-edge distance for the chosen material. The minimum hole-to-edge distance for each material can be found on our Materials Page under the “Design Considerations” heading. .

Rivet Holes: Standard edge distance for A4 and A5 = 10mm. Bolt Holes: Minimum edge distance, Rmin, AN-3 through AN-8 bolts in 6061-T6 and 4130: R = Edge distance radius. Zenith Aircraft Company www.zenithair.com . EDGE FINISH Sheet metal is cut with shear, snips, saw etc. As a general rule all primary structural tension members 2.2 The minimum distance between a counterbore to an edge should be four times the thickness of the metal sheet. 2.3 The minimum distance between a counterbore to a bend should four times the thickness of the metal sheet + bend radius. 3. Countersinks: These are conical-shaped holes created in a metal sheet to hold a countersunk bolt or screw . We’d need to calculate 0.209”/2 + 0.063” to find the minimum distance from the center of the tapped holes to the nearest cut feature.. The minimum distance for a 1/4-20 tap in 0.125” 5052 aluminum is 0.167”.. Then, measure the distance from the center of the hole to be tapped to the nearest cut edge.

Hole-to-edge distance Slot-to-bend distance Slot-to-edge distance SHEET METAL GUIDE V2.2 — TOLERANCES. Notches & Tabs DIMENSIONS The minimum thickness a notch must maintain is at least 0.04” (1mm) or the material’s thickness, whichever is greater; the length must be no larger than 5 times its

Wha are the rules for minimum and maximum edge distance? . 3xs diameter. The two hole duplication methods are called? Back drilling and marking. The preferred marking medium for aluminum alloy is the common no.2 pencil. . FALSE. What is the distance from the center of the rivet to the nearest edge of a sheet called by the Boeing a/c company .Prepare properly sized mounting hole in sheet. Do not perform any secondary operations such as deburring. Step 2. Place shank of self clinching nut into mounting hole, preferably the punch side. Step 3. With punch and anvil surfaces parallel, apply squeezing force until the head of the self clinching nut comes into contact with the sheet material.It is recommended that the minimum distance between the burring hole edge and other burring hole edge should be greater than or equal to 4 times the sheet metal thickness. Where, C = Burring hole spacing t = Sheet metal thickness

Things such as the distance between the two holes, the distance between a hole and the edge, diameter of the hole and slot with respect to the thickness of the sheet metal matters. . Distance = 3 x Sheet Metal Thickness + Bend Radius. Consideration of all of the above guidelines is a must for successful notching and avoid future implications .Study with Quizlet and memorize flashcards containing terms like Drill diameters are grouped by three size standards, When drilling a hole for rivet installation the proper hole will have a clearance of___greater than the largest tolerance of the rivet shank diameter., T or F The edge distance required when using flush fasteners is the same as when protruding -head fasteners . L Bending. 1) Factors determining the minimum L bending. As the middle of the press brake V groove is hollow, when forming, the edge fold must be longer than the hollow section and the specific landing edge size varies in the production of different companies (the lower section of V groove is under use for a long time, the R angle increases, which makes the .

electrical junction box dubai

electrical junction box sizes

The Model 300300-53-01 is an aluminum diamond plate standard length low side truck bed tool box and has a storage capacity of 4.4 cu ft. The Black ARMOR TUF® Powder Coat finish ensures years of dependability. Mounting brackets ensure an easy installation without drilling into the rails.

sheet metal hole distance from edge|sheet metal rib design guidelines