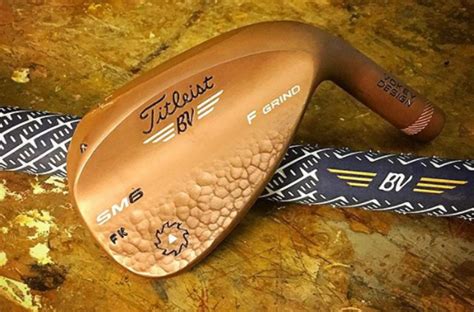

cnc golf club manufacture Beautiful and exotic yet fully functional made using ultra precision 5-axis CNC micro milling manufacturing technology not normally used with golf clubs. Typical electrical junction boxes used for receptacle installation to accommodates a single receptacle are 2" x 4" metal or plastic boxes of varying depth. Choose a deeper box if you .

0 · jeff sheets cnc

1 · custom made clubs

2 · custom club design

3 · cnc hand milled putter

4 · cnc cutting machine

Later this year, we will cover the other one which addresses General Requirements. The 1910.305 Standard covers many safety issues. 1. Wiring Methods; 2. Cabinets, boxes and fittings; 3. Electrical switches; 4. Enclosures for damp or wet locations; 5. Conductors for general wiring; 6. Flexible cords and cables; 7.

Beautiful and exotic yet fully functional made using ultra precision 5-axis CNC micro milling manufacturing technology not normally used with golf clubs.We use cookies to improve your experience on our website. By browsing this .To track your order please enter your Order ID in the box below and press the .Putter CNC machining and manufacturing. CNC mill from block, raw forgings and castings.

35 years of designing and crafting the finest golf clubs available. Utilizing the latest technology, traditional, proven designs, forged from the finest materials, and 100% cnc machined. . Make An AppointmentOver 200-minutes of CNC milling per club, straight from a solid block of 1020 carbon steel, made to perfection. The DI.2 is our new version of our popular original signature driving iron. Penetrating ball flights are now even better with .Introducing The All-New Seven MB (muscle back) FULL CNC Iron! The Seven MB is a groundbreaking new design that features the best golf-specific milling technology Japan has to offer. We can produce more distance, tighter .We used precision multi-axis CNC machining to fabricate the entire club head from a single block of D2 steel. CNC machining is fast, accurate, doesn’t require any fixed tooling and is ideal for shaping the complex geometry of the part.

In this article, we’ll take a closer look at what CNC milling is and how it’s being used to create high-quality golf clubs that are tailored to each individual player. CNC milling is . CNC machines that manufacturers use range anywhere from 150k to over 1 million, all depending upon options that range from a big 3 axis machine being around 200 to 350k to .

jeff sheets cnc

If you put an engineer with a love of golf together, you get Sink Golf – a company located in West Sussex that manufactures golf putters. This South Coast manufacturer has recently invested in a Dugard 760 machining .A total of nine manufacturing operations are required to create a beautiful, custom putter to the highest tolerances only attainable from CNC precision machining. Final assembly is performed .Beautiful and exotic yet fully functional made using ultra precision 5-axis CNC micro milling manufacturing technology not normally used with golf clubs.Putter CNC machining and manufacturing. CNC mill from block, raw forgings and castings.

35 years of designing and crafting the finest golf clubs available. Utilizing the latest technology, traditional, proven designs, forged from the finest materials, and 100% cnc machined. . Make An AppointmentOver 200-minutes of CNC milling per club, straight from a solid block of 1020 carbon steel, made to perfection. The DI.2 is our new version of our popular original signature driving iron. Penetrating ball flights are now even better with improved distance, sound and feel.

Introducing The All-New Seven MB (muscle back) FULL CNC Iron! The Seven MB is a groundbreaking new design that features the best golf-specific milling technology Japan has to offer. We can produce more distance, tighter accuracy with better spin rates while using traditional lofts based on a 47* pitching wedge.We used precision multi-axis CNC machining to fabricate the entire club head from a single block of D2 steel. CNC machining is fast, accurate, doesn’t require any fixed tooling and is ideal for shaping the complex geometry of the part. In this article, we’ll take a closer look at what CNC milling is and how it’s being used to create high-quality golf clubs that are tailored to each individual player. CNC milling is a precise manufacturing process that uses computer-controlled machines to remove material from a .

CNC machines that manufacturers use range anywhere from 150k to over 1 million, all depending upon options that range from a big 3 axis machine being around 200 to 350k to a full bore 5 axis machine that costs start at 500 to 600k. If you put an engineer with a love of golf together, you get Sink Golf – a company located in West Sussex that manufactures golf putters. This South Coast manufacturer has recently invested in a Dugard 760 machining centre from Dugard Machine Tools to machine its bespoke golf clubs.A total of nine manufacturing operations are required to create a beautiful, custom putter to the highest tolerances only attainable from CNC precision machining. Final assembly is performed by a veteran club maker of 30 years.

Beautiful and exotic yet fully functional made using ultra precision 5-axis CNC micro milling manufacturing technology not normally used with golf clubs.Putter CNC machining and manufacturing. CNC mill from block, raw forgings and castings.

custom made clubs

35 years of designing and crafting the finest golf clubs available. Utilizing the latest technology, traditional, proven designs, forged from the finest materials, and 100% cnc machined. . Make An Appointment

Over 200-minutes of CNC milling per club, straight from a solid block of 1020 carbon steel, made to perfection. The DI.2 is our new version of our popular original signature driving iron. Penetrating ball flights are now even better with improved distance, sound and feel.

Introducing The All-New Seven MB (muscle back) FULL CNC Iron! The Seven MB is a groundbreaking new design that features the best golf-specific milling technology Japan has to offer. We can produce more distance, tighter accuracy with better spin rates while using traditional lofts based on a 47* pitching wedge.We used precision multi-axis CNC machining to fabricate the entire club head from a single block of D2 steel. CNC machining is fast, accurate, doesn’t require any fixed tooling and is ideal for shaping the complex geometry of the part. In this article, we’ll take a closer look at what CNC milling is and how it’s being used to create high-quality golf clubs that are tailored to each individual player. CNC milling is a precise manufacturing process that uses computer-controlled machines to remove material from a . CNC machines that manufacturers use range anywhere from 150k to over 1 million, all depending upon options that range from a big 3 axis machine being around 200 to 350k to a full bore 5 axis machine that costs start at 500 to 600k.

If you put an engineer with a love of golf together, you get Sink Golf – a company located in West Sussex that manufactures golf putters. This South Coast manufacturer has recently invested in a Dugard 760 machining centre from Dugard Machine Tools to machine its bespoke golf clubs.

custom club design

cnc hand milled putter

Oil-based paints are arguably the better choice for painting metal. Although it can take longer to dry, when it is dry, it’s durable enough to resist stains, chips, and marks. While it easily covers surface imperfections, it also .

cnc golf club manufacture|cnc hand milled putter