how to bend galvanized sheet metal It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. The Weather Proof Junction Box is a vital security camera mounting accessory to protect the pigtail coming out of your surveillance camera. This junction box is rated IP66 for outdoor use .

0 · how to bend flat metal

1 · folding sheet metal at home

2 · bending sheet metal by hand

3 · bending galvanized sheet metal

4 · bend sheet metal without brake

5 · bend sheet metal at home

6 · bend metal without a brake

7 · bend 16 gauge sheet metal

From smaller waterproof boxes for electronics to large weatherproof electrical enclosures, we offer a variety of styles, sizes, and materials to choose from. With a watertight gasket, sealed enclosures are guaranteed to keep electronic and electrical equipment safe in wet conditions.

how to bend flat metal

electric power box bdsm

folding sheet metal at home

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

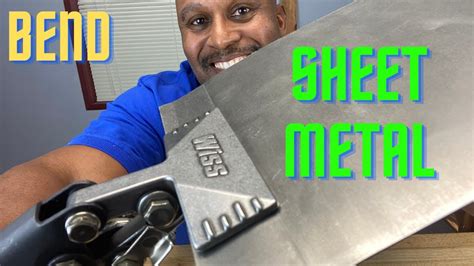

109,817 views • Dec 13, 2020 • #sheetmetals #metalbender #Caliber8Tools. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges.more..It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Because the fabricator does the forming or bending, the most common time to bend the steel is before it is hot-dip galvanized. When galvanized steel is bent after the coating has formed, there is no issue with cold work, but there can be .Galvanized steel is a resilient and corrosion-resistant metal, which makes it an ideal component in many projects. Bending the galvanized steel can help you mold it into shapes appropriate for your project. The bending process is fairly simple, but you should feel confident operating power tools before you attempt to bend the galvanized steel.

electric shock box game

Galvanized steel is a resilient and corrosion-resistant metal, which makes it an ideal component in many projects. Bending the galvanized steel can help you mold it into shapes appropriate for your project. The bending process is fairly simple, but you should feel confident operating power tools before you attempt to bend the galvanized steel. With the assistance of this jig, you can confidently embark on your DIY project, knowing that you have the tools and techniques necessary for bending corrugated metal roofing. Weakening the Metal for Bending. Before diving into the bending process, it is crucial to weaken the targeted area on the corrugated metal roofing for a successful bend. This video is presented by TBK Metal, an Expert in Metal Design, Engineering & Fabrication for Architectural Projects.www.tbkmetal.comEmail: [email protected] you want good sharp bends, get a sheet metal shop to do it for you. They'll probably supply the material cheaper than Menards. Galvanized metal is hard to glue; the zinc coating repels adhesives. Nails will work if you pre-drill for them. Another alternative would be to use solid zinc sheet instead of galvanized steel. It's soft and easier .

I was building raised vegetable garden and thought I'd try to bend the panels (makes round corners) and keep them in one piece instead of cutting them.I have.From left to right: Galvanized Steel, Brass, Steel, Copper, Aluminum. . and a mallet, you can fashion a rudimentary bending brake. Mark a bend line and place the sheet metal on the edge of your bench. Next place the wood parallel and slightly behind the bending line. Clamp the wood on top of the metal to the workbench. Finally, bend the sheet .Step #5 Clamping the Sheet Metal. After measuring and marking the bend line, the next step is clamping the sheet metal. Here are the key actions to take in this phase: Position the Sheet Metal: Place the sheet metal in the bending machine or workbench, aligning it with the bend line. On top of that, accurate positioning ensures a precise bend.

*Friends! I'm from Ukraine. We need your financial support! PayPal* [email protected] this video I will show you how I make a sheet metal bending tool.#.

Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are typically used for sheet metal bending in communication devices due to the need for high precision and the irregular shape of the bend.. The basic principle of the .

Bending the galvanized steel can help you. Galvanized steel is a resilient and corrosion-resistant metal, which makes it an ideal component in many projects. Bending the galvanized steel can help you. İçeriğe atla +8618522522113 [email protected] 360° Sanal Tur. Ev; Ürünler.

Bending, Cutting, Notching, And Folding Standing Seam Metal Roofing Panels. Detailed How To Instructions For Standing Seam Panels At The Eave Ends Of The Roo.

Galvanized steel is a resilient and corrosion-resistant metal, which makes it an ideal component in many projects. Bending the galvanized steel can help you mold it into shapes appropriate for your project. The bending process is fairly simple, but you should feel confident operating power tools before you attempt to bend the galvanized steel.If the flame burns the galvanized coating, it will turn black, and it'll make soldering extremely hard from that point on. 5 - You may want to grab an acid cup and brushes. Option #2 - Welding galvanized steel. Welding galvanized steel is . While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, plate steel varies in strengths from mild varieties to .Bending the galvanized steel can help you. Galvanized steel is a resilient and corrosion-resistant metal, which makes it an ideal component in many projects. Bending the galvanized steel can help you. Chuyển đến nội dung +8618522522113 [email protected] 360° Tham quan ảo.

A simple one piece tool tray is shown being fabricated from scrap metal. The process highlights the way dimensions of the box come to life by cutting the ap.

https://sendcutsend.com/Send Cut Send - Online Laser Cutting, Waterjet Cutting and CNC Router ServiceIn this video: The second video in our new series on ben. To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a. . Techniques for fabricating sheet metal include cut-and-bend, roll-forming, stamping, and deep drawing. Each technique requires different skills and tools to produce quality results. A bending radius three times the thickness will ordinarily ensure a satisfactory galvanized product for steel with normal composition, i.e. a carbon content between 0.20 and 0.25 percent. If design specifications require sharp bends on heavy material, aluminum-killed steel or other non-aging steels should be specified.

This post continues the series on building a chicken coop. The previous post, Finishing the Chicken Coop Structure, shows how the coop looks with tar paper in place.The outside of the coop will be covered in corrugated tin roofing recycled from a friend’s house. We picked some of the better pieces (those without holes or serious bends) from the selection. Push the metal around the corner or edge to form a 90-degree bend. Press 1 palm firmly against the metal where it sits against the surface to hold it steady. Use your other hand to push the other side of the metal all the way around the corner until it’s bent at a 90-degree angle down the middle. [5]

Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. . If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box will not come out as you hope .

Bending metal flashing involves using a metal brake to bend sheet metal. You can use this if you are building your own sunroom. Poor flashing will result in .

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Search Now. . Galvanized steel is available to counter this issue. This comes with a hard wearing pre-applied zinc coating that prevents rust. Aluminum - First used for aircraft production .

Finally, make sure the sheet is filed down smoothly, because otherwise you may get cracks in the metal. Place Forms and Sheet in Vise: Your form blocks should have the exact shape for bending your metal angle. When you clamp the sheet metal into the vise’s grip, make sure the bend lines on your blocks and sheet match up.

Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting electrical wiring systems.

how to bend galvanized sheet metal|bending sheet metal by hand