parts of sheet metal soldering Step-by-Step Guide to Soldering Galvanized Sheet Metal. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. This step is crucial in ensuring a clean and smooth . Fuse box diagram (fuse layout), location, and assignment of fuses .

0 · will solder stick to steel

1 · will solder hold metal together

2 · soldering different metals together

3 · solder for galvanized sheet metal

4 · how to solder metal together

5 · can you solder metal together

6 · can sheet metal be soldered

7 · best solder for galvanized steel

Vynco Home. Standard Switches 250V; Cover Plate only; Permanent Connection Unit 250V; Horizontal Powerpoints 250V; Vertical Powerpoints 250V; Card Switch 250V; . Distribution Boxes. Flush Distribution Boards. V Series Plastic Boards; V Series Box Ahead - Plastic; Economy Range - Plastic; VM Series Metal Boards; Flush Meter Boards.

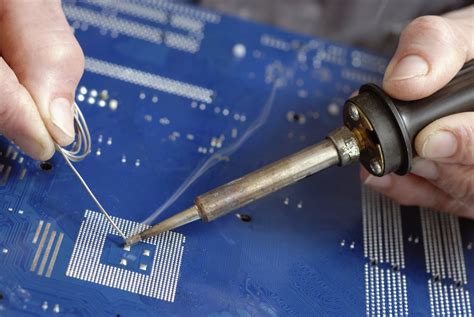

In this comprehensive guide, we explore the necessary supplies and techniques to help you master the art of sheet metal soldering. With each step, you'll discover the critical supplies you need and learn the practical skills that will enable you to work with precision and confidence.

Step-by-Step Guide to Soldering Galvanized Sheet Metal. Start by cleaning the surface of the sheet metal using a suitable cleaning agent and a scrub brush or sponge. This step is crucial in ensuring a clean and smooth .

How to SOLDER Sheet Metal. basics of how to solder using muriatic acid, cFLUX, map gas, and tri-bar solder. Key Takeaways. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures compared to the base . Electrical connections and sheet metal are soldered with a soldering iron or gun. Wiping is a method used for joining lead pipe and also the lead jacket of underground and other lead-covered cables. Sweated joints . But when it comes to soldering mild steel, it requires knowledge of the proper techniques and materials to ensure a strong and secure bond. Read on to learn how to solder mild steel correctly for optimal results.

will solder stick to steel

Soldering is a joining process used to join different types of metals, usually made of tin and lead which is melted using a hot iron and cooled to create a bond.

Soldering is commonly used in electric and electronic applications, Sheet metal work wire terminals, sealing of metal containers, and similar small parts. You might like: What is the Difference Between TIG & MIG Welding? . When you are soldering any type of sheet metal, it is very important to choose the right flux. Flux is made of an activator and a carrier that allows the solder to “wet” to the base metal surfaces. The flux removes the oxides from .

Shop Premium and Standard Express Soldering Irons and Soldering Kits for Roofers and Sheet Metal Workers, Roof Flux, Copper Turbo Long-Life Soldering Tips and Solder Accessories at Panther East and Black Cat Fasteners. . Patriot Parts and Accessories; View all; Brands. Brands; Most popular; AA Melters ASE - All Seasons Amped Equipment. Flux: Use a flux designed explicitly for soldering galvanized sheet metal. It helps remove oxidation and promotes better adhesion. Lead-Free Solder: Opt for lead-free solder to avoid health risks. Make sure it is suitable .

will solder hold metal together

Shop our collection of sheet metal soldering supplies available for order online. . Perkeo Soldering Unit, Tips and Parts Ransome and Johnson Furnaces Sievert Soldering Kits, Tips and Parts Solder Bar & Solder Wire - Leaded & Lead-Free .

NOW REPAIR POT METAL PARTS BEFORE PLATING WITHOUT DRILLING OR PUTTIES ; Perfect for: Joining and Repairing Pot Metal and Zinc Die Cast Parts, . Essmetuin Special Core Solder Wire For Stainless Steel/Nickel Sheet/Zinc Flake/Copper/Iron Sheets/Aluminum Soldering, Multifunctional Core Solder Wire 1.0mm(0.04in) 1.4oz/2pack .A plier-style handpiece confines heat to only where it touches when you’re treating, brazing, and silver soldering small parts. Economy Instant-Heat Soldering Guns. These guns heat up the instant you pull the trigger and . Traditionally used for sheet metal work, heat the heads of these coppers with an external flame source and they store .Work may involve any of the following: setting up and operating fabricating machines to cut, bend, and straighten sheet metal; shaping metal over anvils, blocks, or forms using hammer; operating soldering and welding equipment to join sheet metal parts; or inspecting, assembling, and smoothing seams and joints of burred surfaces.Buy DYOG Solder Aluminum Flux, 10ml Aluminium Soldering Liquid, Soldering Accessories for Battery, Strong and Metal Parts Soldering, . Follow the safety precautions and guidelines included with the aluminum sheet solder to ensure safe handling and use.2. Store flux in a cool, dry place away from direct sunlight and heat sources.3. .

soldering different metals together

Soldering galvanized steel can be challenging due to the zinc coating on the surface of the metal. If the soldering isn’t performed correctly, the life span of the joint might be shorter than desired. . Sheet Metal Soldering Materials . it is important to use the right flux to properly bond the parts. In general, a zinc chloride based . Part Number F3942 : Item Weight 2.47 ounces : Product Dimensions 9.84 x 6.3 x 1.57 inches : Country of Origin Taiwan : Item model number . FIRSTINFO Auto Body Sheet Metal Plate Micro Welding Soldering Clamp FIRSTINFO Precision Alignment L,T, I Type Sheet Metal Welding Clamp

Sheet Metal Benders Sheet metal benders have become an essential tool to the professional tinsmith. These types of tools act as portable brakes and allow the worker to bend metal onsite without having to rely on a heavy brake in the back of the truck or in the shop. . From metal roofing, to slate, to soldering; these items are consistently . Applying Heat & Solder. The next step is to begin heating up your soldering iron (or torch). You want to heat it up until it reaches around 700 degrees Fahrenheit for mild steel soldering. Then take your solder wire—which should be made from 95% lead/5% tin alloy—and place it in between both pieces of metal where they meet each other.

Features: Economical with high efficiency and low power consumption (Energy-saving type) Wooden grip has good heat insulation. You can shape the copper tip to suit your work. (Nickel-plated) Product Specifications Model HP-200 Voltage 220V, 240V AC 50/60Hz Power Consumption 150W Heater Nichrome Heater Length 370mm Cable Length 1.5M Weight 610g .

This includes metal parts and the solder, which must have suitable melting points and thermal characteristics. It is essential to ensure the materials are compatible to create strong and durable bonds. . Shengen is the place to go. We specialize in sheet metal laser cutting, bending, surface finish, and sheet metal welding.Benoit Sheet Metal provides the sheet metal industry with quality new & used sheet metal machinery. We feel our success is based on our ability to serve you, the customer, with outstanding service as well as provide the highest quality American-made products. . Soldering; Parts & Consumables; Forming. Benders; English Wheels; Forming Stakes . The Best Flux for Sheet Metal. Not only is flux required for soldering, but it is important to choose the right flux for your particular type of sheet metal. The best flux for sheet metal should be a strong and active flux . Soldering metal with Kristin Hanson.This video was created by Kollabora.com, a new maker community where you can find DIY projects and buy the best supplies..

Browse many different soldering iron and machine replacement parts here at Stellar Technical Products. Get everything you need for soldering projects. . Sheet Metal Soldering Materials Heavy Duty Electric Soldering Irons Perkeo . Sweat soldering is used to join medium-to-large pieces of metal. Each piece is tinned, and the parts are positioned with their tinned sides against each other. Heat is applied to the center of the top sheet until the solder begins to melt. A large soldering gun is ideal for this kind of application as it provides plenty of heat.Steel auto body parts are an easy fix with Super Alloy 1. DIY auto body repair tips: Repair a steel auto body door panel with your own torch. Currency: 866-684-4993 Login . 350º F multi-metal solder joins pot metal and all white metals, in any combination Melting Temperature: 350°F / . Talking about soldering a seam on sheet metal (steel). I am using an electric iron, acid flux and 50/50 lead/tin solder. This is NOT for food use.

solder for galvanized sheet metal

Johnson's "J-33 Galvanized Flux" is the superior choice for soldering galvanized sheet metal seams. This flux for soldering galvanized steel is an active chloride formulation with more strength than just plain muriatic acid. This steel solder flux is designed for galvanized steel soldering but can also be used on copper. basics of how to solder using muriatic acid, cFLUX, map gas, and tri-bar solder.

A plier-style handpiece confines heat to only where it touches when you’re treating, brazing, and silver soldering small parts. . Traditionally used for sheet metal work, heat the heads of these coppers with an external flame source . Often used to solder aluminum to difficult-to-solder metal such as stainless steel and nickel, this flux .

We use this technique in bonding two metal parts by using a melted filler metal. Soldering and blazing will make sure that your product is strong and durable. You can use soldering and blazing in plumbing, jewelry, and electronic parts. Related Resources: Soldering And Brazing. 5. Assemble Sheet Metal With Tongue And Groove Because the solder wire will heat up, you want to put some distance between you and the end of the solder. Have a damp sponge accessible to wipe off any excess solder from the tip of your soldering iron. By now the soldering iron is probably heated and ready. Definitely wear safety glasses because hot solder can pop.This cordless hose-free soldering iron is equipped with a self-igniting Piezo Electric ignition for immediate use in any application, making it one of the best butane soldering irons for roofers and sheet metal contractors. The Express 6364e Soldering Iron Kit comes with a copper turbo tip #678 that can adjust 360° and be angled ± 5°. The .

The sheet metal fabrication industry relies on several techniques to join two metal parts together than using nuts and bolts. Amongst the popular types, the two most commonly employed metal joining processes are welding and soldering.

how to solder metal together

can you solder metal together

If you're working with Wago 224 Series connectors, you'll want this multi-purpose electrical junction box. Known as the WAGOBOX Light, it's easy to fit and easy to work with. The enclosure supports up to three cables, with a conductor size of 0.5 to 2.5mm².•

parts of sheet metal soldering|soldering different metals together