cutting slots in sheet metal Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once . With a typical thickness ranging from 0.5 millimeters to 6 millimeters, sheet metal is a choice material in the automotive industry for its lightweight yet sturdy characteristics, enhancing both efficiency and safety.

0 · what is slotting in engineering

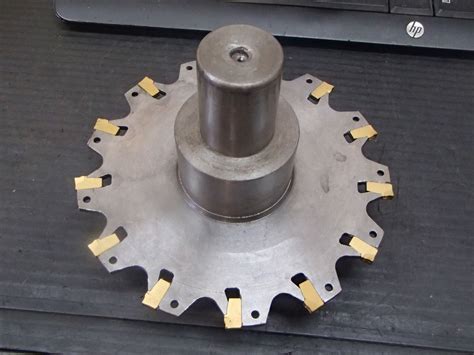

1 · slotting vs profiling machining

2 · slotting tool for milling machine

3 · slotting cutters milling

4 · slot drill vs end mill

5 · open ended slots milling

6 · difference between slot and groove

7 · cutting slotted holes in steel

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

Consider these important design tips when creating holes and slots in sheet metal parts.More information on this Tech Tip available at: https://rapidmanufact. Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once . All you need is a drill and a counter so follow this video and you can cut a slot, a circle or any shape in metal.Mark the shape and size of the slot you want to cut in the sheet metal using the marker. Drill a hole over the marked area on the sheet metal. Make sure you are using a drill bit for metal surfaces and always select a drill bit that is slightly .

Your best bet for making these slots would probably be a Dremel (or similar) with a cutoff wheel. Another option would be to simply punch the slots with a sheet . The best technique for cutting slots in sheet metal is to make a series of small, shallow cuts rather than trying to cut through the metal in one pass. This will help you maintain control and ensure that the slots are straight .

Locate the sheet metal over the milled aluminum slot. Put them in an hydraulic press with a hard rubber pad (the sole of an old sport's shoe will work) over the slot area. .There are a variety of suitable cutting processes for sheet metal, but we’ll be focusing on the most common processes used to prepare sheet metal blanks for bending: waterjet, laser cutting, and punch pressing.Consider these important design tips when creating holes and slots in sheet metal parts.More information on this Tech Tip available at: https://rapidmanufact. Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once made a guide sized for outlets when I had 8 outlets to cut .

All you need is a drill and a counter so follow this video and you can cut a slot, a circle or any shape in metal.Mark the shape and size of the slot you want to cut in the sheet metal using the marker. Drill a hole over the marked area on the sheet metal. Make sure you are using a drill bit for metal surfaces and always select a drill bit that is slightly smaller than the mark.Your best bet for making these slots would probably be a Dremel (or similar) with a cutoff wheel. Another option would be to simply punch the slots with a sheet metal punch. Not sure exactly what tool would be best. The best technique for cutting slots in sheet metal is to make a series of small, shallow cuts rather than trying to cut through the metal in one pass. This will help you maintain control and ensure that the slots are straight and even.

Locate the sheet metal over the milled aluminum slot. Put them in an hydraulic press with a hard rubber pad (the sole of an old sport's shoe will work) over the slot area. Press and when you hear a pop the slot will be "punched". The edges of the slot will be smooth.

what is slotting in engineering

slotting vs profiling machining

There are a variety of suitable cutting processes for sheet metal, but we’ll be focusing on the most common processes used to prepare sheet metal blanks for bending: waterjet, laser cutting, and punch pressing. One workaround here is to cut the slot through the bend, eliminating the need to leave material to come around. In the example in the related image, the top slot will deform badly, the bottom slot will not. Narrow slots, like the slot on the left, can also be a problem.

Slotting is one of the simplest operations here, working with a rectangular tool to cut a rectangular slot in a sheet metal piece. Nibbling is using a combination of many overlapping punches to create different kinds of figures in a sheet metal piece.

Consider these important design tips when creating holes and slots in sheet metal parts.More information on this Tech Tip available at: https://rapidmanufact. Angle grinder and/or 2~3" air cutoff cool can work to piece sheet metal. Air nibbler does wonders IF you clamp a guide to the metal, 3/16" oversized to what you need. I once made a guide sized for outlets when I had 8 outlets to cut . All you need is a drill and a counter so follow this video and you can cut a slot, a circle or any shape in metal.

Mark the shape and size of the slot you want to cut in the sheet metal using the marker. Drill a hole over the marked area on the sheet metal. Make sure you are using a drill bit for metal surfaces and always select a drill bit that is slightly smaller than the mark.Your best bet for making these slots would probably be a Dremel (or similar) with a cutoff wheel. Another option would be to simply punch the slots with a sheet metal punch. Not sure exactly what tool would be best. The best technique for cutting slots in sheet metal is to make a series of small, shallow cuts rather than trying to cut through the metal in one pass. This will help you maintain control and ensure that the slots are straight and even.

Locate the sheet metal over the milled aluminum slot. Put them in an hydraulic press with a hard rubber pad (the sole of an old sport's shoe will work) over the slot area. Press and when you hear a pop the slot will be "punched". The edges of the slot will be smooth.There are a variety of suitable cutting processes for sheet metal, but we’ll be focusing on the most common processes used to prepare sheet metal blanks for bending: waterjet, laser cutting, and punch pressing. One workaround here is to cut the slot through the bend, eliminating the need to leave material to come around. In the example in the related image, the top slot will deform badly, the bottom slot will not. Narrow slots, like the slot on the left, can also be a problem.

slotting tool for milling machine

sheet metal processing company pequot mn

16g will do nicely for the floors and chassis but it will take some beating into place, it's nice and thick for welding. 18g (1.2mm) is a good compromise.

cutting slots in sheet metal|difference between slot and groove