u-pull junction box calculations Sizing Tips for Pull Boxes and Junction Boxes. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s): • Left to . Shop from a trusted distributor of designer furniture upholstery fabrics sold by the yard at affordable prices. Brands include Waverly, P Kaufmann, Sunbrella, Richloom, Premier Prints, .

0 · underground junction box size calculator

1 · u pull box size calculator

2 · junction box size chart

3 · junction box size calculator

4 · how to calculate underground pull box

5 · how to calculate pull box

6 · electrical pull box calculator

7 · angle pull box calculation

Din Rail kit for UP Squared metal AL chassis (EP-CHUPSMTVAUPS) include L shape Din Rail plate for UP Squared AL chassis and Universal DIN Rail Mounting Clips 20mm width Sturdy and Versatile Clips onto 35mm DIN rail **UP Squared metal chassis is not included.

Pull Box Calculator. The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as .Pull Box Sizing. Cable Tray Sizing. Cable Tray Cables 2000 Volts or Less. .

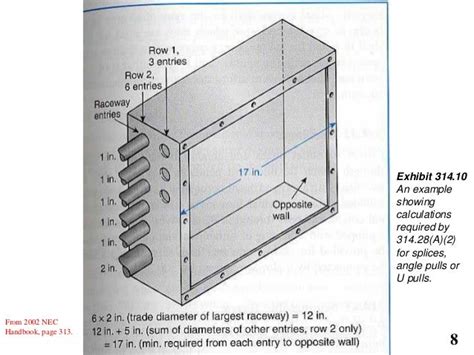

To correctly apply 314.28 (A) (1), just multiply the largest raceway size by eight. The box must be at least as long as that number. Angle pulls, u-pulls, and splices. Of course, junction boxes are used for reasons other than .Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to .

Sizing Tips for Pull Boxes and Junction Boxes. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s): • Left to .When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s): Pull boxes, junction boxes, and conduit bodies must be sized to allow conductors 4 AWG and larger to be installed without damage to the conductor insulation. The NEC provides sizing requirements in Sec. 314.28.This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According .

A U pull is where two raceways enclosing the same conductors are located on the same wall of a box. Calculate a box containing both angle and U pulls by the same method as angle pulls. .

The sizing requirements for pull boxes, junction boxes, handhole enclosures and conduit bodies exist to prevent conductor insulation damage. Those requirements are in .

The National Electrical Code (NEC) has specific requirements detailing how to calculate the maximum numbers of conductors in boxes (outlet, device, junction, pull, etc.) and conduit bodies. Provisions for boxes and conduit bodies .Boxes containing conductors of 4 AWG or larger, under 600 volts, are calculated from the sizes and numbers of raceways. Where pull and junction boxes are used on systems over 600V, the installation must comply with the provisions in 314.70. Calculation procedures are provided for three types of pulls: straight, angle and U. In this article, we will discuss the pull box and junction box sizing for 25mm2 (4 AWG) conductors (or cables) or larger. . Box Length (angle pull calculation) = 53x6+35+35=388 mm. Box Length .Where pull and junction boxes are used on systems over 600 volts, the installation must comply with the specifications in 314.70. Three types of calculation procedures are provided: straight pull, angle pull and U pull. Last month's column discussed U pulls. This month, the discussion continues with U-pull calculations. 314.28(A)(2) Angle or U .

Calculations are different for pull and junction boxes. Boxes containing conductors of 4 AWG or larger, under 600V, are calculated from the sizes and numbers of raceways (see Figure 1). Where pull and junction boxes are used on systems over 600V, the installation must comply with the provisions in Part IV of Article 314. Discover the key differences between junction box vs pull box in electrical installations. Learn which one fits your specific needs. . U-Pull Calculations: Similar to angle pulls; Count entry/exit points separately; Example with 5″ conduit: Basic calculation: .Title : Pull- and Junction-Box Calculations, Part IV. Sponsored Content : No Exclusive Content : No Display in Table of Contents : No Article date : Oct 15, 2005, 06:30 AM 314.28 Pull and Junction Boxes. The National Electrical Code covers outlet, device, pull and junction boxes; conduit bodies; fittings; and handhole enclosures in Article .Where pull and junction boxes are used on systems over 600 volts, the installation must comply with the specifications in 314.70. Last month’s column discussed U pulls. This month, the discussion continues with pull- and junction-box calculations. .

Section 370-28 provides specific instructions for calculating the dimensions of pull or junction boxes. Two calculation methods are provided—straight pulls and angle or “U” pulls. Last month’s In Focus covered the instructions for sizing pull or junction boxes containing straight pulls. Boxes containing angle or “U” pulls are .Where pull and junction boxes are used on systems over 600 volts, the installation must comply with the specifications in 314.70. Last month’s column discussed U pulls. This month, the discussion continues with pull- and junction-box calculations. .The National Electrical Code covers outlet, device, pull and junction boxes; conduit bodies; fittings; and handhole enclosures in Article 314. As stated in the scope (314.1), this article covers the installation and use of all boxes and conduit bodies used as outlet, device, junction or pull boxes, depending on their use, and handhole enclosures.

Quick Tips for Pull Box Sizing. Tips for learning: Pull box calculations become easier with more practice. Use practical field examples to practice calculations. Draw up some sample pull boxes and calculate them. Obtain drawings from a completed project and “reverse engineer” the box sizes by calculating them. Assuming that I'm correct that since the conductors don't exit directly across from each other, the calculation would be (6x4")+4"+4" = 32" so a 32" x 32" box. My real question is concerning the depth of the pullbox. Do I use Table 312.6(A) to calculate the depth? I am installing (4) 400kCMIL, so I see that as 12". Is that correct? This electrical box fill calculator (or in short, box fill calculator) will help you determine the total box fill volumes you will need to meet so that each of your electrical utility boxes will pass the National Electrical Code®.In this calculator, you will learn: The importance of electrical box fill calculation; How to calculate box fill volumes yourself;

Of course, junction boxes are used for reasons other than simply making a straight pull easier.28(A)(1) and (A)(2). Two sections refer to box fill calculations: 314. Junction Box Size Sizing Junction Boxes. 16(A) shows the minimum permitted box volume to be 18 in.Determining the size of underground314.28 Pull and Junction Boxes The National Electrical Code (NEC) has specific requirements detailing how to calculate the maximum numbers of conductors in boxes (outlet, device, junction, pull, etc.) and conduit bodies. Provisions for boxes and conduit bodies enclosing conductors 18 AWG through 6 AWG are in 314.16. These boxes are calculated from the sizes and numbers .

underground junction box size calculator

u pull box size calculator

So the end result of this "no wires shown" pull box sizing exercise was a minimum 24" x 17" pull box. In reality, the installer is more than likely to upsize to 24" x 18" or even 24" x 20". However, we begin to creep into the .

This month, the discussion continues with pull- and junction-box calculations. 314.28(A) Minimum-Size Pull and Junction Boxes. Before the 1999 edition of the NEC, splices were not a factor when sizing pull and junction boxes. Starting with the 1999 edition, 314.28(A)(2) became applicable with not only angle pulls and U pulls, but also with . Welcome to the YouTube channel that supports your business with knowledge and tips on electrical, fire, and life safety.With instant digital access to codes .

junction box size chart

Boxes containing conductors of 4 AWG or larger, under 600 volts, are calculated from the sizes and numbers of raceways. Where pull and junction boxes are used on systems over 600V, the installation must comply with the provisions in 314.70. Calculation procedures are provided for three types of pulls: straight, angle and U.

junction box size calculator

Boxes and conduit conduit bodies used as pull or junction boxes shall comply with 314.28 (A) through (E). . This is simply just a friendly reminder to adequately size your conduit and use that size for calculations if a cable is used. Thanks for looking out NEC 😉. 314.28 continues, and there’s a few exceptions but the remaining is pretty .When installing insulated conductors of 4 AWG or larger, the minimum dimensions of pull or junction boxes installed in a raceway or cable run must comply with 314.28(A)(1) through (A)(3).The rules apply to “insulated” conductors for a reason. When installing large insulated conductors, care must be taken to ensure that the conductor insulation is not compromised .314.28 Pull and Junction Boxes The National Electrical Code (NEC) has specific requirements detailing how to calculate the maximum numbers of conductors in boxes (outlet, device, junction, pull, etc.) and conduit bodies. Provisions for boxes and conduit bodies enclosing conductors 18 AWG through 6 AWG are in 314.16. These boxes are calculated from the sizes and numbers . 2. what is the minimum vertical size of the junction box. 3. what is the minimum distance for the 2" conduits next to each other on the bottom for a u pull. my answers #1 minimum horizontal size is 8*2 + 2 + 2 = 20" . pull box size calculations The question is badly worded, in that it does not make clear which runs are straight and which have .

Article 314.28 A ( Minimum size Pull and Junction boxes and conduit bodies)states that if the conductor is #4 or larger, the following box calculation will be used and so forth. Ive been arguing this fact for months with other electricians and designers that say if the Belden cable diameter is equal to #4, you have to use this article.

how to calculate underground pull box

Study with Quizlet and memorize flashcards containing terms like A 2" raceway runs along a 3" raceway into a junction box with an angled pull. Assuming the system operates at 600V, the required distance between these two raceways entries is, An enclosure for use in an area subjected to regular washdown is, Any underground conductor that enters a raceway, box or . U-Pull Box is that where the wires get into and leave the electrical box via the same side. Types of Pull Box. Junction Box Sizing. You do not need to perform any calculations when sizing a junction box because it is standardized. Rather, look through the chat in NEC 314.16 to establish the minimum and maximum volume of your electrical junction . 314.28 Pull and Junction Boxes and Conduit Bodies keywords : junction boxes Last time I checked splices could be made in junction boxes. My point is that the NEC gives the minimum dimensions required. If you feel you need more room get a bigger box. The minimum you would need (taking lock-nuts into consideration) is 16''bye3''bye3'' .

Universal Roofing & Sheet Metal is a GAF certified roofing contractor. Get an estimate, read reviews, or see job photos & certifications.

u-pull junction box calculations|underground junction box size calculator