how does a cnc milling machine work The exact movements that this code controls depends on the type of CNC machine that is being used. Let’s take a look at some of the most common CNC machines in use today, and how they work: Types of CNC Machines #1 CNC milling machines. CNC milling is one of the most common types of CNC machining, known for its great accuracy and tolerances .

$5,900.00

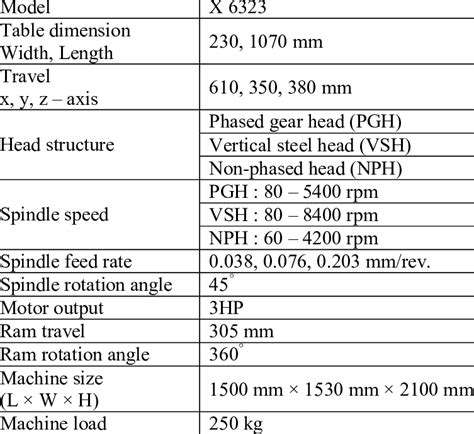

0 · specifications of cnc milling machine

1 · milling process step by

2 · introduction to cnc milling machine

3 · cnc milling tutorial

4 · cnc milling explained

5 · cnc milling diagram

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

The Habitat ReStore carries new and gently used lighting, including fixtures, lamps, .

November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady hand (or lack thereof) makes all the . A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for .

CNC Milling Process: This entails the use of computer numerical control (CNC) machinery to accurately remove material from a workpiece. The essential principles involve translating a digital design into numerical codes .

Learn how CNC milling works, what machines are used and what operations are possible. Compare conventional and climb milling, horizontal and vertical mills, and suitable . How Does a CNC Milling Machine Work? The operation of a CNC milling machine involves several steps: Step 1: Creating the CAD Model: A machinist uses CNC software such as Autodesk Fusion 360, SolidWorks, or AutoCAD to create a CAD (Computer-Aided Design) model of the specific component. Once the design is complete, it serves as a blueprint for .The exact movements that this code controls depends on the type of CNC machine that is being used. Let’s take a look at some of the most common CNC machines in use today, and how they work: Types of CNC Machines #1 CNC milling machines. CNC milling is one of the most common types of CNC machining, known for its great accuracy and tolerances .

How do the CNC Machines Work? A majority of CNC machines require software programs to run. They employ CAM (Computer Aided Machining). CAM is a software package that creates Numerical Control (NC) codes and tool paths. .

What Is a Milling Machine and How Does It Work? Milling is a common form of machining in the manufacturing industry. A milling machine works by using a rotary cutting tool to remove material from a workpiece to create different products and parts. There are two MAIN types of milling machines: Vertical milling machines; Horizontal milling machines

Converting from CAD file format to machine language. CNC milling machines do not directly read and interpret 3D models in CAD format. Specialised CAM (computer-aided manufacturing) software programs must first convert the CAD files into a CNC machine-readable programming language known as G-code (Geometric code). The CAM software analyses the imported 3D .CNC Service Starts at , Get for New Users: https://jlc3dp.com/

How Does a CNC Machine Work? A CNC machine works by following a computer-aided design (CAD) file, which is a digital model of the part or object that needs to be created. This CAD file is then converted into a set of numerical data, called G-code, that tells the CNC machine how to move. The machine can cut, shape, drill, or engrave materials . A cnc milling machine is a tool that is used to work and shape solid materials. The workpiece moved and shaped against a rotating cutter. Can be operated manually by hand or mechicanically automated.Check out Xometry. It's probably going to be a lot cheaper then most work they do but as for getting small jobs and getting paid, it's great. I'm fortunate to have a mutual shop I work out of. And most of the stock I use is free leftover scrap. Manual Milling vs. CNC Milling. When it comes to milling machines, there are two main types: manual milling machines and CNC milling machines. Each type has its own advantages and considerations that need to be taken into account depending on the specific machining requirements. Let’s explore the differences between manual milling and CNC .

specifications of cnc milling machine

A computer numerical control (CNC) milling machine is a mill that uses computer code to understand where to make cuts. Like all milling machines, a CNC mill produces a final piece by carving away from a block of material versus adding layers of material to a blank slate. However, unlike manual milling, CNC mills do not have to be operated by hand.

milling process step by

How Does A 3 Axis CNC Milling Machine Work? Simply put, a 3-axis CNC milling machine is a machine that automatically engraves. Take a look at how it works. Step 1: Design Components. Design the desired part using CAD (Computer Aided Design) software such as AutoCAD, SolidWorks, and Fusion 360. How Does a CNC Machine Work? CNC Milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a block (known as a blank or workpiece) and shape it into a finished part. The process begins with a CAD model, which is then converted into a CNC program and set up in the CNC machine. . One of the advantages of CNC milling machines is they can produce the same part repeatedly. Low scrap rates, quicker turnovers on larger quantities, accuracy, and the ability to handle the most complex geometry are all reasons to turn to the CNC mills instead of the manual mill. Some Milling Machines Transition Between CNC and ManualIn a CNC milling machine, rotating cutting tools move relative to the workpiece to remove material. The cutting tool (also called a milling tool) is fixed on a spindle that can rotate. The rotation and movement of the spindle give CNC milling machines the ability to perform three or more axes milling operations. CNC Drilling

The X and Y axes typically control the horizontal movements of the cutting tool, while the Z axis controls the vertical movements. These axes are critical for precise, three-dimensional milling. Which Axes Do CNC Milling .

CNC machines are automated milling devices that manufacture industrial components without direct human assistance. They use coded instructions sent to a computer, allowing factories to make parts accurately and quickly. The CNC .And as technology takes giant strides forward, the versatility and capabilities of CNC milling machines grow accordingly. How Do CNC Milling Machines Work? The operation of a CNC milling machine might seem daunting, but when broken down, the process is quite straightforward. The journey from raw material to finished product involves a series of .

Multi-Axis CNC Milling Machine. Multi-axis CNC milling machine can cut at different angles and move along different aces. There are several kinds of multi-axis milling machines: 2-axis milling machines. 2-axis milling machines can work as a workpiece in the x and z axes. Therefore, they can cut vertically and horizontally in one direction.

CNC Machine Components. Understanding the key components of a CNC machine is crucial to grasping how they work. Here are the main parts: Computer and Controller: The brain of the operation, responsible for interpreting the programming and controlling the machine’s movements. Machine Tool: The actual cutting or shaping tool, such as a drill, lathe, . What is a CNC machine? Scrolling through your social media, you have probably come across videos of machines carving materials into various shaped objects in. How Do CNC Machines Work? CNC machines usually feature a version of a CAD software program. A CAD program, or computer-aided design, is software which allows you to draw what you want to cut. . Router vs Milling. CNC router and CNC milling machines are two of the most popular CNC machines today. While both cut materials, it’s the type of .

3. Benefits of CNC Milling Machine. CNC milling machines play an important role in advancing manufacturing techniques, offering a range of benefits that enhance production across various industries. Here are the benefits: Increased Accuracy. CNC milling machines deliver incredible accuracy, making sure parts come out with exact dimensions every . How does a CNC Mill work? Let's see an example of SYIL X5, our miniature milling machine that can cope with tasks of various difficulty. It is a very precise.

cnc machine operator jobs in california

CNC milling machines automate the production process, reducing the need for human intervention and thereby reducing errors. . The MX software is designed to work seamlessly with your CNC Masters machine. It is made to work with Windows PC – desktop, laptop, or an all in one – on standard USB. Use it on Windows 8 or 10 64-bit operating .

cnc machine operator job description pdf

How Does a CNC Router Compare to a CNC Milling Machine? They work similarly, with a tool like an endmill mounting in a spinning motor. Both typically drive the tool in 3 axes. The big difference is CNC routers are more often used in soft materials like woods and plastics and CNC mills are used more for cutting metal. 3-Axis Milling: This is the most common type of CNC milling, where the tool moves along three axes—X, Y, and Z. It’s ideal for simple geometries and parts with planar cuts. 4-Axis Milling: A 4-axis machine has an additional rotational axis, typically rotating the workpiece along the X or Y axis. This capability allows for cutting on .

introduction to cnc milling machine

Learn how to properly wire a lighting junction box for safe and efficient electrical connections. Step-by-step guide for professional results.

how does a cnc milling machine work|basics of the cnc mill