electrical enclosure installation in ordinary locations Providing guidelines for the selection, installation, and protection of electrical equipment to prevent ignition of hazardous atmospheres. Ensuring safety through established protection techniques like explosion-proof enclosures, intrinsic . Most wholesalers sell 4 terminal 20amp joint boxes, and 3 terminal 30amp. The 20amp ones get used for lighting circuits. The larger the current rating, the more it can carry. And as your loading will be no higher than 5amp, a joint box with a .

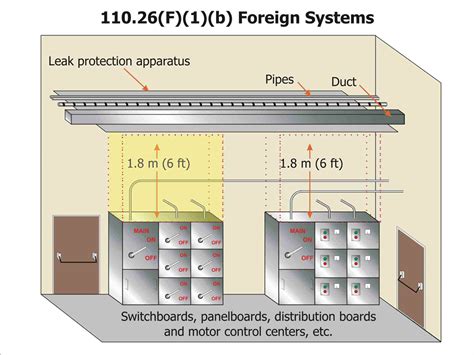

0 · working space for electrical equipment

1 · osha regulations for electrical installations

2 · osha electrical enclosure regulations

This is the end to a rod that runs across the entire downstairs ceiling (above the plaster), exiting on the opposite exterior wall. The decorative plates and nuts were then tightened to clamp the .

working space for electrical equipment

Providing guidelines for the selection, installation, and protection of electrical equipment to prevent ignition of hazardous atmospheres. Ensuring safety through established protection techniques like explosion-proof enclosures, intrinsic .

Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other .

Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location. . A hazardous area guide can help simplify hazardous location classes, divisions & groups as defined in the National Electrical Code (NEC), or NFPA 70. Keeping an easy-to-read guide within view can help ensure that .

lōk) are places where fire or explosion hazards may exist. Sources of such hazards include gases, vapors, dust, fibers, and flyings, which are combustible or flammable. Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and re.The following requirements apply to all electrical installations and utilization equipment, regardless of when they were designed or installed: § 1910.303(b)—Examination, installation, and use of .All ordinary locations models are UL Listed and are controlled via an adjustable electric or mechanical thermostat. Recently introduced electric models are completely self-contained, are .Providing guidelines for the selection, installation, and protection of electrical equipment to prevent ignition of hazardous atmospheres. Ensuring safety through established protection techniques like explosion-proof enclosures, intrinsic safety, and purging/pressurisation.

osha regulations for electrical installations

Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location. Requirements for each of these options are as follows: A hazardous area guide can help simplify hazardous location classes, divisions & groups as defined in the National Electrical Code (NEC), or NFPA 70. Keeping an easy-to-read guide within view can help ensure that anyone entering a .

Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.The following requirements apply to all electrical installations and utilization equipment, regardless of when they were designed or installed: § 1910.303(b)—Examination, installation, and use of equipment § 1910.303(c)(3)—Electrical connections—Splices § 1910.303(d)—Arcing parts § 1910.303(e)—MarkingAll ordinary locations models are UL Listed and are controlled via an adjustable electric or mechanical thermostat. Recently introduced electric models are completely self-contained, are “plug and play” and can be top or side mounted and maintain the NEMA 4/4X rating of .

Cabinets, cutout boxes, fittings, boxes, and panelboard enclosures in damp or wet locations must be installed so as to prevent moisture or water from entering and accumulating within them. In wet locations the enclosures must be weatherproof.

Be installed according to instructions provided by the manufacturer including mounting means, electrical wiring connections and routing, ventilation, required spacing between components, and required protective devices; and. Not exceed their marked electrical and environmental ratings. In North America, equipment meeting relevant hazardous area location certifications first must meet ordinary location requirements. These “ordinary” standards include but are not limited to: UL 1581 standard for electrical wires, cables and flexible cords.Providing guidelines for the selection, installation, and protection of electrical equipment to prevent ignition of hazardous atmospheres. Ensuring safety through established protection techniques like explosion-proof enclosures, intrinsic safety, and purging/pressurisation.

Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.Electrical installations. Equipment, wiring methods, and installations of equipment in hazardous (classified) locations shall be intrinsically safe, approved for the hazardous (classified) location, or safe for the hazardous (classified) location. Requirements for each of these options are as follows:

A hazardous area guide can help simplify hazardous location classes, divisions & groups as defined in the National Electrical Code (NEC), or NFPA 70. Keeping an easy-to-read guide within view can help ensure that anyone entering a .Electrical equipment installed in such locations can provide an ignition source, due to electrical arcing, or high temperatures. Standards and regulations exist to identify such locations, classify the hazards, and design equipment for safe use in such locations.

The following requirements apply to all electrical installations and utilization equipment, regardless of when they were designed or installed: § 1910.303(b)—Examination, installation, and use of equipment § 1910.303(c)(3)—Electrical connections—Splices § 1910.303(d)—Arcing parts § 1910.303(e)—Marking

osha electrical enclosure regulations

All ordinary locations models are UL Listed and are controlled via an adjustable electric or mechanical thermostat. Recently introduced electric models are completely self-contained, are “plug and play” and can be top or side mounted and maintain the NEMA 4/4X rating of . Cabinets, cutout boxes, fittings, boxes, and panelboard enclosures in damp or wet locations must be installed so as to prevent moisture or water from entering and accumulating within them. In wet locations the enclosures must be weatherproof.Be installed according to instructions provided by the manufacturer including mounting means, electrical wiring connections and routing, ventilation, required spacing between components, and required protective devices; and. Not exceed their marked electrical and environmental ratings.

farmington metal fabrication

Corrugated metal roofing is essentially made from metal sheets that are roll-formed into metal panels. The roofing material is also something referred to as exposed fastener panels, as each fastener is visible on the panel’s surface after installation.

electrical enclosure installation in ordinary locations|osha electrical enclosure regulations