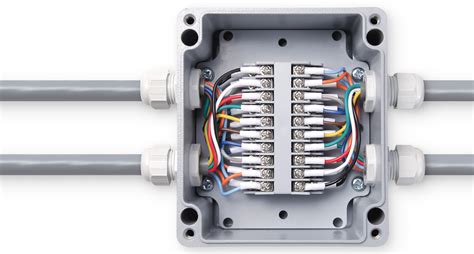

cutout size for us electric junction boxes The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG . A deep drawing is a manufacturing technique that transforms a metal sheet into a three-dimensional form through mechanical action. Usually executed using a punch, die, and other tools, this method is perfect for hollow, axisymmetrical parts.

0 · types of electrical junction boxes

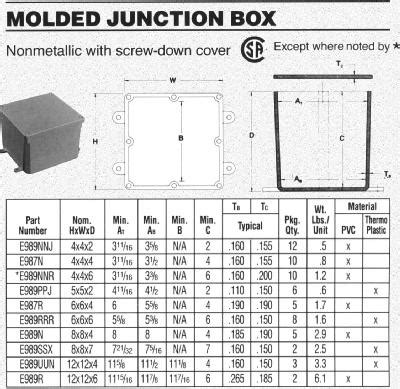

1 · standard electrical junction box size

2 · pvc junction box size chart

3 · junction box sizing chart

4 · junction box size calculator

5 · electrical junction box size chart

6 · electrical junction box size calculator

7 · electrical box sizing chart

The rules for pull boxes, junction boxes, and outlet boxes cover five areas. In summary: Minimum size [314.28(A)]. These requirements constitute most of Sec. 314.28. One key point is that on straight pulls the box or conduit .

Standard North American junction boxes come in a variety of shapes and sizes (round, octagon, square, rectangular); however, most wiring devices intended for junction box mounting, save for light fixtures, are . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your . The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG .

The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat . Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and .By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account .

Effortlessly calculate the required electrical junction box size for your wiring project using our Electrical Junction Box Size Calculator. Input the number of conductors and select the box .

Common household wiring is usually 16, 14, or 12 AWG. As an example, the code allows 2 cubic inches of space for each 14-AWG conductor, so if you have two cables with three conductors each (a total of six), you’ll need a . Standard North American junction boxes come in a variety of shapes and sizes (round, octagon, square, rectangular); however, most wiring devices intended for junction box mounting, save for light fixtures, are designed around the standard device yoke mounting pattern -- this is defined in NEMA WD-6 (an abridged version can be found here) as a 4 . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).

mori-say 867 cnc machine

types of electrical junction boxes

The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat buildup. Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors.Effortlessly calculate the required electrical junction box size for your wiring project using our Electrical Junction Box Size Calculator. Input the number of conductors and select the box type to get accurate results.

Common household wiring is usually 16, 14, or 12 AWG. As an example, the code allows 2 cubic inches of space for each 14-AWG conductor, so if you have two cables with three conductors each (a total of six), you’ll need a box that’s 4″ .

Standard North American junction boxes come in a variety of shapes and sizes (round, octagon, square, rectangular); however, most wiring devices intended for junction box mounting, save for light fixtures, are designed around the standard device yoke mounting pattern -- this is defined in NEMA WD-6 (an abridged version can be found here) as a 4 . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

The sizing requirements for pull boxes, junction boxes, handhole enclosures, and conduit bodies exist to prevent conductor insulation damage. Those requirements are in 314.28, and they apply to all conductors 4 AWG and larger ( Fig. 1 ).The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat buildup.

Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.By accurately sizing your junction box, you ensure compliance with safety standards, prevent potential electrical issues, and optimize space usage. The calculator takes into account several factors, such as the type of conduit, conductor size, and the number of conductors.

standard electrical junction box size

Effortlessly calculate the required electrical junction box size for your wiring project using our Electrical Junction Box Size Calculator. Input the number of conductors and select the box type to get accurate results.

motionmaster cnc router parts

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

cutout size for us electric junction boxes|types of electrical junction boxes