advantages of cnc milling machine pdf By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors. By definition, a junction box is an enclosure made of plastic or metal that houses the electrical wiring connections, protecting them from the elements and from vandalism.

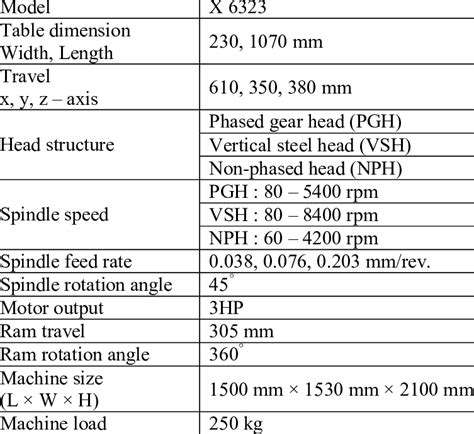

0 · specifications of cnc milling machine

1 · pros of cnc machining

2 · limitations of cnc milling

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machine pros and cons

6 · cnc machine advantages and disadvantages

7 · advantages and disadvantages milling process

Cardboard: Thin, stiff pasteboard used in the creation of playing cards, signs, etc. Term is often misused to refer to Boxboard (folding cartons) and Containerboard (corrugated boxes). .

By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors.

6. Advantages of CNC systems CNC machines can be used continuously and only need to be switched off for occasional maintenance. These machines require less skilled people to .Advantages of CNC technology. There are two primary benefits to CNC machines: a. CNC machines allow multiple axes of simultaneous motion, resulting in 2D and 3D contouring .By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

6. Advantages of CNC systems CNC machines can be used continuously and only need to be switched off for occasional maintenance. These machines require less skilled people to operate unlike manual lathes/milling machines etc. CNC machines can be updated by improving the software used to drive the machines.Advantages of CNC technology. There are two primary benefits to CNC machines: a. CNC machines allow multiple axes of simultaneous motion, resulting in 2D and 3D contouring ability. In other words, a CNC milling machine can move and endmill along a sloped line or circular trajectory (which requires simultaneous X and Y motion), or a CNC lathe

specifications of cnc milling machine

for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly automated machine tools such as turning centre and machining centre which change the cutting tools. What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.CNC manufacturing offers advantages on two types of parts: (1) simple parts that are mass produced and/or (2) complex parts with features requiring multiple axes of simultaneous motion. For simple

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.Prototyping (RP) and the advantages and disadvantages of each. • List the tools and equipment required for this course. • List the major lesson topics covered by this course.But there are plenty of other advantages to 5-axis machining. The process uses shorter cutting tools, which means the spindle speed of the machine is higher and cutting time is faster. Shorter cutting tools often result in better surface finishes as well.By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating parts with loose rotational symmetries, such as camshafts or centrifugal compressors.

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

6. Advantages of CNC systems CNC machines can be used continuously and only need to be switched off for occasional maintenance. These machines require less skilled people to operate unlike manual lathes/milling machines etc. CNC machines can be updated by improving the software used to drive the machines.Advantages of CNC technology. There are two primary benefits to CNC machines: a. CNC machines allow multiple axes of simultaneous motion, resulting in 2D and 3D contouring ability. In other words, a CNC milling machine can move and endmill along a sloped line or circular trajectory (which requires simultaneous X and Y motion), or a CNC lathefor machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly automated machine tools such as turning centre and machining centre which change the cutting tools. What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.

CNC manufacturing offers advantages on two types of parts: (1) simple parts that are mass produced and/or (2) complex parts with features requiring multiple axes of simultaneous motion. For simpleWhat is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

Prototyping (RP) and the advantages and disadvantages of each. • List the tools and equipment required for this course. • List the major lesson topics covered by this course.

pros of cnc machining

Ga. is different from inches, there is no conversion formula. Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below.

advantages of cnc milling machine pdf|advantages and disadvantages milling process