solidworks export sheet metal dxf Exporting Sheet Metal Parts to DXF or DWG Files. You can create *.dxf files of . $349.99

0 · solidworks export dxf with dimensions

1 · solidworks export dxf from assembly

2 · solidworks export 3d dwg

3 · solidworks dxf to sketch

4 · solidworks dxf export problems

5 · export solidworks sketch as dxf

6 · export solidworks drawing to dwg

7 · convert dwg to solidworks drawing

Sheet metal fabrication is an integral process in modern manufacturing, used to produce components for industries ranging from aerospace to electronics. However, like any engineering process, it’s prone to defects. Issues such as burrs, cracks, and warping can compromise product quality, cause delays, and escalate costs. Understanding these defects, their underlying .

You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export Dxf files to other applications, such as punch press or laser-cutter programming software.

To open this PropertyManager: With a part open, do one of the following: Save the .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an .

Exporting Sheet Metal Parts to DXF or DWG Files. You can create *.dxf files of .You can create *.dxf files of sheet metal flat patterns from sheet metal part .

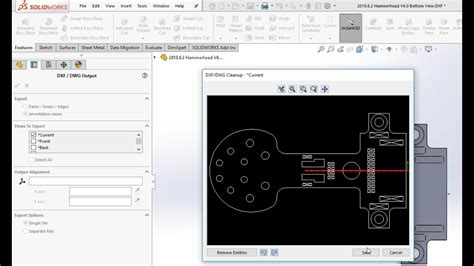

Exporting Sheet Metal Parts to DXF or DWG Files. You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . Did you know that generating a DXF file from the flat pattern of your SOLIDWORKS Sheet Metal part can be achieved in just a few seconds? Let’s walk through it using an example of a battery tray designed for a radio . During the DXF export process the various entity types can be mapped to defined layers with specified line color and format. Many lasers, routers, plasma, and waterjet sheet . With a sheet metal part open, either right-click a face of the part and select Export to DXF/DWG or select Save As from the File dropdown list and then select DXF or DWG as the file type. In the Properties Manager, select .

DXF files play a pivotal role in CAD design, enabling seamless data exchange between different software programs. Understanding how to import and export DXF files in SolidWorks, address common issues, and .

You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, .Creating DXF Files of Sheet Metal Flat Patterns You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without Easiest way to export the Sheet Metal geometry to DXF/DWG is to right-click on the body in the graphics window and choose ‘Export to DXF/DWG’.

Is there simply way to export flat patterns from multi body/sheetmetal part? Or do I need to create drawing for each sheetmetal and then save each drawing to dxf?

Sheet Metal. If you are exporting sheet metal, as per the example you linked, then you will output a flat pattern. However if you try to export sheet metal with a model that does not contain any sheet metal features then the result will be that the call returns false and nothing is output. The following would be suitable for a sheet metal part:Under Custom Map SOLIDWORKS to DXF/DWG, select Enable. Set other export options and click OK. In the DXF/ DWG Output . Click OK. Exporting a Bounding Box. When exporting a sheet metal part as a .dxf or .dwg file, you can export the bounding box and assign the bounding box to a specific layer. To assign the bounding box sketch to a layer: .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the .

Thought this might be useful to some of you. If you open an assembly and run the macro, it will export PDF's of any drawings (in the same folder as the Assembly) then find all the parts with Sheet Metal. It exports a DXF file for the unfolded flat pattern and builds a BoM as a CSV for just the sheet metal parts. PART NAME MATERIAL THICKNESS(mm .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software.

most precise cnc machine quotes

An expanded set of geometric entities is available when you export a sheet metal flat pattern. Exporting Drawings as DXF or DWG. You can export drawings as DXF or DWG files. You can set the options. Preserving SOLIDWORKS Drawing Layers on DXF/DWG Export. You can preserve SOLIDWORKS layers when exporting drawings to DXF or DWG files.Flat Patterns dxf Files; Exporting Bend Line Directions You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the different bend line directions to separate layers when you export the part. Exporting a Bounding BoxHopefully mine will be simple. At the moment on a sheet metal part to get it to a flat pattern .dxf file I - right click the "flat-pattern" feature "export to DXF / DWG" on the drop down bar Save as In the same file location as the part itself I change the name to "File name - Flat-Pattern" Save under the DXF / DWG Output I select, Sheet metal .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the .

In the SOLIDWORKS to DXF/DWG Mapping dialog box: Assign layers to entities. Map other properties. Click OK. Exporting a Bounding Box. When exporting a sheet metal part as a .dxf or .dwg file, you can export the bounding box and assign the bounding box to a specific layer. To assign the bounding box sketch to a layer: Click File > Export As.Export active sheet only : Export all sheets to separate files: Writes each drawing sheet to a file of the specified file name, prepended by a number. For example, 00_filename.dwg and 01_filename.dwg. Export all sheets to one file : Export all drawing sheets to paper spaceIn the SOLIDWORKS to DXF/DWG Mapping dialog box: Assign layers to entities. Map other properties. Click OK. Exporting a Bounding Box. When exporting a sheet metal part as a .dxf or .dwg file, you can export the bounding box and assign the bounding box to a specific layer. To assign the bounding box sketch to a layer: Click File > Export As.

You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export Dxf files to other applications, such as punch press or laser-cutter programming software.

You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. . You can map bend line directions to specific layers when you export sheet metal models as .dxf or .dwg files. For example, in sheet metal parts with up and down bend directions, you can map the .manipulation of, the DXF/DWG export system options. Changing these settings will only be maintained for the duration of the export. Upon completion of the export, the DXF/DWG export settings in the Solidworks system options are returned to their original values. - When making a Solidworks MACRO BUTTON, make sure to specify the methodYou can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software.> Sheet Metal > Sheet Metal Parts > Exporting Sheet Metal Parts to DXF or DWG Files. SOLIDWORKS Help Other versions: | Print | Feedback on this topic : Welcome to SOLIDWORKS Online Help: Help: Legal Notices: Administration: User Interface: Fundamentals: 3DEXPERIENCE Add-Ins : Moving from 2D to 3D .

Export sheet metal to dxf. SW By Stefan Wozniak 11/30/13. Is there simply way to export flat patterns from multi body/sheetmetal part? Or do I need to create drawing for each sheetmetal and then save each drawing to dxf? . ©2002-2024 Dassault Systemes SolidWorks Corporation .You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export .dxf files to other applications, such as punch press or laser-cutter programming software. When exporting a SOLIDWORKS sheet metal part to DXF/DWG, you have the option to save different entities to separate layers. With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the industry.

When exporting sheet metal parts to DXF, you get extra lines caused by countersinks, or chamfers. Obviously, this causes problems when cutting sheet metal on a laser because the laser makes cuts on both lines and you end up with a hole the diameter of the OD of the chamfer rather than the OD for the given screw size.I have a multibody sheet metal part. I am facing problem in exporting flat-pattern dxf's of the two bodies. The major problem is when exporting the dxf of the body named 'Back Big'. When I export it, its bendlines are missing. Sometimes when exporting flat pattern of the body named 'Back Small', incorrect results are found. Please help me in this.Visit https://mlc-cad.com/ to learn more about Sheet Metal Training, Support, and Tech TipsIf you need to export a sheet metal flat pattern to different laye.

solidworks export dxf with dimensions

Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide explains some of the ways to help get the best results when welding thin sheet metal.For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low .

solidworks export sheet metal dxf|export solidworks sketch as dxf