cnc machine learning CNC-Net constitutes a self-supervised framework that exclu-sively takes an input 3D model and subsequently gener-ates the essential operation parameters required by the CNC machine to . $125.00

0 · free online cnc training courses

1 · free online cnc programming training

2 · free cnc training online

3 · free cnc training near me

4 · free cnc machine operator training

5 · cnc machine training free

6 · cnc machine basic knowledge

7 · basics of cnc machine learning

$224.99

As such, we have highlighted five best practices, discovered through our research, namely the following: 1. Focus on the data infrastructure first. 2. Start with simple models. 3. . Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, .

CNC-Net constitutes a self-supervised framework that exclu-sively takes an input 3D model and subsequently gener-ates the essential operation parameters required by the CNC machine to . In this paper, applications of machine learning and artificial intelligence systems in CNC machine tools is reviewed and future research works are also recommended to present an overview.This review delves into the dynamic intersection of machine learning, AI, and CNC machine tools, exploring the synergistic relationship between these domains and their transformative impact on modern manufacturing.

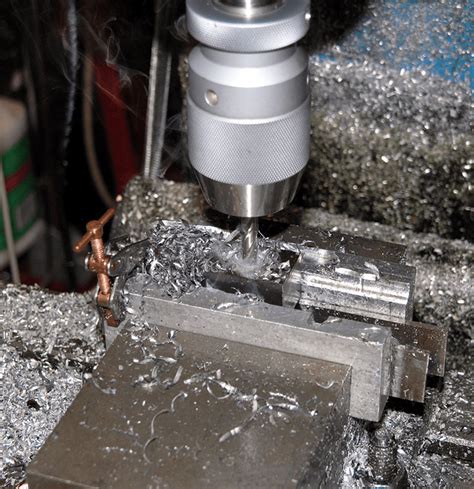

By utilizing machine learning algorithms, CNC machines can monitor various parameters, such as motor currents, temperature, and vibration, to detect anomalies and predict potential. Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining.

Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining.

We take a look at two areas that are expected to really make an impact within CNC systems: machine learning and artificial intelligence, or “AI.” Artificial intelligence—whether from software-based algorithms, smart probes . In this paper, applications of machine learning and artificial intelligence systems in CNC machine tools is reviewed and future research works are also recommended to present an overview of current research on machine learning and artificial intelligence approaches in CNC machining processes.

free online cnc training courses

china two spindle row drilling machine cnc router factory

As such, we have highlighted five best practices, discovered through our research, namely the following: 1. Focus on the data infrastructure first. 2. Start with simple models. 3. Beware of data leakage. 4. Use open-source software. Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, leading to reduced waste, faster production times, and .

CNC-Net constitutes a self-supervised framework that exclu-sively takes an input 3D model and subsequently gener-ates the essential operation parameters required by the CNC machine to construct the object. In this paper, applications of machine learning and artificial intelligence systems in CNC machine tools is reviewed and future research works are also recommended to present an overview.This review delves into the dynamic intersection of machine learning, AI, and CNC machine tools, exploring the synergistic relationship between these domains and their transformative impact on modern manufacturing.

By utilizing machine learning algorithms, CNC machines can monitor various parameters, such as motor currents, temperature, and vibration, to detect anomalies and predict potential. Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining.

chris marks metal fabrication

Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining. We take a look at two areas that are expected to really make an impact within CNC systems: machine learning and artificial intelligence, or “AI.” Artificial intelligence—whether from software-based algorithms, smart probes or voice command—is one half . In this paper, applications of machine learning and artificial intelligence systems in CNC machine tools is reviewed and future research works are also recommended to present an overview of current research on machine learning and artificial intelligence approaches in CNC machining processes. As such, we have highlighted five best practices, discovered through our research, namely the following: 1. Focus on the data infrastructure first. 2. Start with simple models. 3. Beware of data leakage. 4. Use open-source software.

Artificial Intelligence (AI) is revolutionizing CNC machining by enhancing precision, efficiency, and automation. AI algorithms optimize cutting paths, predict machine maintenance, and enable real-time adjustments, leading to reduced waste, faster production times, and .CNC-Net constitutes a self-supervised framework that exclu-sively takes an input 3D model and subsequently gener-ates the essential operation parameters required by the CNC machine to construct the object.

In this paper, applications of machine learning and artificial intelligence systems in CNC machine tools is reviewed and future research works are also recommended to present an overview.This review delves into the dynamic intersection of machine learning, AI, and CNC machine tools, exploring the synergistic relationship between these domains and their transformative impact on modern manufacturing. By utilizing machine learning algorithms, CNC machines can monitor various parameters, such as motor currents, temperature, and vibration, to detect anomalies and predict potential.

Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining.Therefore, the purpose of this work is to practically illustrate several best practices, and challenges, discovered while building an ML system to detect tool wear in metal CNC machining.

free online cnc programming training

chinese cnc manufacturers

Get the best deals on Green Metal Antique Cabinets & Cupboards when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

cnc machine learning|free cnc machine operator training