general tolerances for sheet metal fabrication Different equipment has different tolerancing capabilities. If features are located on the same surface, we can reliably achieve standard . Our Orlando location produces a range of products, including small, precision sheet metal components to large, complex tubular weldments and assemblies.

0 · typical sheet metal tolerances

1 · steel plate thickness tolerance chart

2 · standard sheet metal tolerances chart

3 · stainless steel sheet tolerance chart

4 · sheet thickness tolerance chart

5 · sheet metal tolerances chart

6 · sheet metal thickness tolerance chart

7 · astm steel sheet tolerance chart

Tuck & Howell provides custom sheet metal services. Call us today for sheet metal fabrication in Greenville, SC and the surrounding area. Financing Schedule NowYou'll love the Design Toscano European-Style Steel Window Box Planter at Wayfair - Great Deals on all products with Free Shipping on most stuff, even the big stuff.

There are three types of sheet metal tolerances: Material, Dimensional, and Geometric. We work with three types of tolerances: Dimensional tolerances: These refer to the variations that are allowed in a part’s physical dimensions. If a piece should be 10 cm long, the patience may .General tolerance ISO 2768 does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. For example, the . We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, . We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These .

Different equipment has different tolerancing capabilities. If features are located on the same surface, we can reliably achieve standard . Sheet metal tolerances describe the allowable variations in shape, size, and geometry for sheet metal fabrication. Metal tolerancing impacts project outcomes in multiple ways, including fit, functionality, manufacturing costs, .

Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from . Knowing general tolerances is important for good sheet metal fabrication. They guarantee quality and consistency in manufacturing while balancing cost-effectiveness and . Here at Protolabs, 3D printing tolerances vary from ± 0.002 in. to ± 0.012 in. (± 0.051mm to 0.305mm). In a sense, sheet metal walks a line between manufacturing and artisan goods. We bend and stretch material to achieve a .Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. .

Industry Standards for Sheet Metal Tolerances. Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768. ISO 2768 is an important standard for general tolerances in sheet metal fabrication. ISO 2768 Part 1 is intended to simplify drawing indications and it specifies general tolerances for linear and angular dimensions without individual tolerance indications in four tolerance classes. It applies to the dimensions of parts that are produced by metal removal or parts that are formed with sheet metal fabrication. The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .

Tolerances of Machined and Sheet Metal Parts Xometry's Manufacturing Partner Network makes thousands of machines available to make your part at the click of a mouse. Since the minimum requirement to machine a part is a solid CAD file, we offer these general tolerances and guidelines (also found in our Manufacturing Standards ).

typical sheet metal tolerances

steel plate thickness tolerance chart

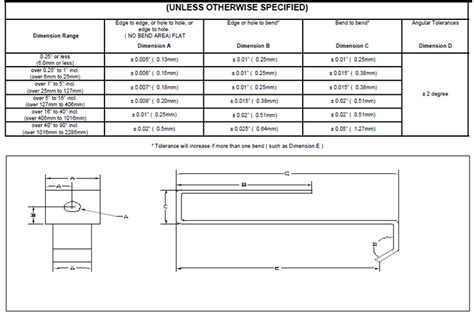

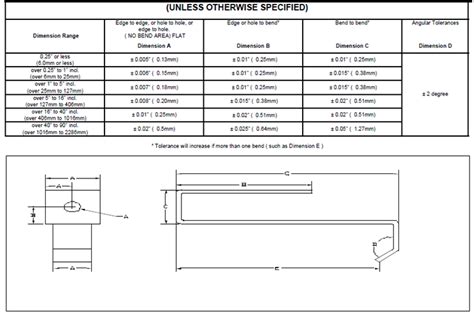

GENERAL DIMENSIONAL TOLERANCES FOR SHEET METAL FORMED PARTS. (UNLESS OTHERWISE SPECIFIED) . ± 0.05" ( 1.27mm) * Tolerance will increase if more than one bend ( such as Dimension E ) ± 0.005" ( 0.13mm) ± 0.006" ( 0.15mm) ± 0.007" ( 0.18mm) ± 0.01" ( 0.25mm) . ± 0.02" ( 0.5mm) Title: tolerance sheet metal.xls Author: Rick Slocum Created . They define the permissible limits of variation in a physical dimension which is a very crucial quality metric in sheet metal fabrication drawings. The International Organization for Standardization (ISO) provides globally recognized standards in sheet metal fabrication through ISO 2768-1:1989. It outlines general tolerances for various aspects .

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . In general, when the hole diameter is less than the material thickness the pierce point will often cause the hole to be out of tolerance. 3D Feature Constraints: .

It is relevant in several industries, such as CNC machining, injection molding and sheet metal fabrication. The main purpose of ISO 2768 is to avoid specifying tolerances for each dimension individually. Instead, this standard defines general tolerances that are valid for the entire part and are based on specified classes. In sheet metal fabrication, tolerances are your best friend. They’re the factors that determine whether your sub-assemblies fit or if you’ll need to go back to the drawing board. . General Tolerances on Symmetry; Ranges of nominal lengths in mm: Tolerance Class H: Tolerance Class K: Tolerance Class L: up to 100: 0.5: 0.6: 0.6: above 100 . For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. General Tolerances. For sheet metal fabrication, there are a few general tolerances that the industry uses everywhere.

BY PRESS WORKING FROM SHEET METAL AND SHEAR FROM METAL PLATES TECHNICAL DATA TECHNICAL DATA Table 1. General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 .IS 2102-1 (1993): General tolerances, Part 1: Tolerances for linear and angular dimensions without individual tolerance indications [PGD 20: Engineering Standards] . removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or .The sheet metal parameters are dependent on the machines & tooling that will be used to bend the parts, which is far from universal between different manufacturers. 3D files - this is the closest to a “universal part” that you will find, as the machine software can unfold sheet metal parts using the specified sheet metal parameters.

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design . Our 'tolerances' are the maximum limits for dimensional variation that we can tolerate before a part is considered .The prevalent standard for sheet metal fabrication is ISO 2768, which covers tolerance requirements across multiple industries while maintaining a balance between costs and processing capabilities. General Tolerances. Sheet metal . Sheet metal tolerances describe the allowable variations in shape, size, and geometry for sheet metal fabrication. Metal tolerancing impacts project outcomes in multiple ways, including fit, functionality, manufacturing costs, .

This post is to help you understand what the holdable tolerance can be for your sheet metal parts. However even for an experienced designer, it may be difficult and time-consuming to decide the tolerances for each and every dimension, an easier approach is to explain to the manufacturer or DFM engineer how the part fits and functions in the assembly, how it interacts with the mating .Sheet metal material stock has general tolerances for thickness. The following table is a quick reference for standard aluminum 5052 material thickness tolerances. Standard stock material tolerances may vary between alloys and treatments. Sheet metal with tighter tolerances sheet can be specified if required. Stock Material Thickness TolerancesThe application of ISO 2768 extends across various manufacturing processes, including machining, casting, and sheet metal fabrication. It is particularly beneficial in the following scenarios: Prototype Development: Provides a fast and effective way to specify tolerances for prototypes, speeding up the development process.GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2) STRAIGHTNESS AND FLATNESS Ranges in nominal Tolerance class lengths in mm H K L up to 10 0.02 0.05 0.1 over 10 up to 30 0.05 0.1 0.2 over 30 up to 100 0.1 0.2 0.4 over 100 up to 300 0.2 0.4 0.8 over 300 up to 1000 0.3 0.6 1.2 over 1000 up to 3000 0.4 0.8 1.6

Completed in early 2015, General Sheet Metal’s (GSM) expanded Sheet Metal Fabrication Shop has over 35,000 square feet of production space to create a wide variety of products. From standard sheet metal fittings and everyday items to complex systems, our shop has seen it all.

ISO 286 Table Hole Tolerances Calculator; International Tolerance Grades ; Variations on dimensions without tolerance values are according to " ISO 2768". All tolerance limits are given in mm. ISO 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for mechanical tolerances. 1.1 This standard covers tolerances on dimensions for fabrication of steel structures manufactured by riveting, bolting or welding. 1.2 The tolerances specified in this standard do not apply to structures like steel railway bridges which require closer tolerances. This post will compare machining, 3D printing, and sheet metal processes and how they affect achievable tolerances. Sheet Metal Fabrication vs. Machining vs. 3D Printing. Machining and 3D printing are highly precise manufacturing methods, accurately removing or adding (respectively) material to produce a final geometry. . Unlock the secrets to mastering sheet metal tolerances and ensure precision in your manufacturing processes. Explore the key factors that contribute to top-notch engineering results. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine . General Tolerances If a drawing or specification sheet has not been provided .

standard sheet metal tolerances chart

ancient roman metal bracket

Your go-to specialists in residential, commercial & custom steel fabrication and field services for over 28 years. Serving Tucson and Southern Arizona.

general tolerances for sheet metal fabrication|sheet metal tolerances chart