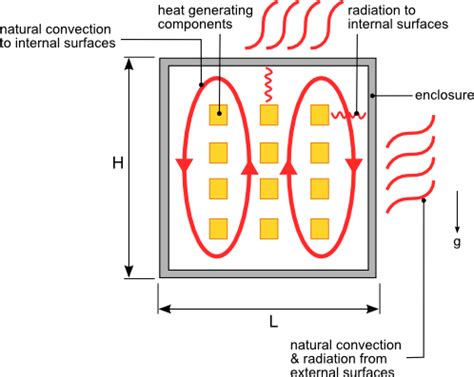

electrical enclosure heat calculator Use this calculator to help you decide: The required cooling or heating capacity of a temperature control product for your enclosure. Whether your enclosure cooling or heating needs will require an air conditioner, air to air heat exchanger, . An ideal coating is non-specular (to decrease geometrical effects), durable, high in reflectance and spectrally flat over a wide wavelength range to give a flat spectral response in input or .

0 · heat dissipation calculation for enclosure

1 · fan enclosure size chart

2 · enclosure heater calculator

3 · enclosure heat load calculator

4 · enclosure cooling calculator

5 · electrical enclosure heater calculator

6 · electrical enclosure heat load calculation

7 · electrical enclosure cooling calculator

Both metal-clad and metal-enclosed switchgear offer different functionalities with their pros and cons. The decision to choose between them is system-specific, depending on your project’s requirements, budget, and safety considerations.

Choose measurement units 2. Enter the enclosure dimensions. 3. Enter your temperature variables 4. Choose mounting/unit option and show results. 5. SCE recommended units. Our free Enclosure Cooling Calculator can help you determine heat load and find the right electrical cabinet cooling solution to meet your needs. Click to get started!Use this enclosure heat calculator to estimate temperature rise inside of an enclosure given dimensions and power load.

By clicking on the part number, cooling performance (Qc) can be viewed graphically over the entire operating range from minimum to maximum voltage or current (Imin to Imax or Vmin to .

Use this calculator to help you decide: The required cooling or heating capacity of a temperature control product for your enclosure. Whether your enclosure cooling or heating needs will require an air conditioner, air to air heat exchanger, .Follow the below steps to calculate Btu per hour: Determine the surface area of the enclosure (in square feet ) exposed to the air, ignoring the top of the cabinet. Determine the temperature differential (in degrees Farenheit) between . An Enclosure Heater Calculator assists in determining the required wattage for heaters in electrical and electronic enclosures. It is especially useful for engineers and technicians working in fields that require precise thermal .

Heat generated by the components: W: Cooling power needed (for air conditioners) W: Air volume needed (for filter fans) m 3 /h: Heat to be supplied (for anticondensation heaters) WOur BTUH calculator estimates the number of BTUs to cool or heat an area based size, insulation, climate, and other factors. Use our BTUH Calculator now!Easily find the wattage needed to heat an enclosure (such as those for ATMs, sensors, gauges, etc.), by entering its dimensions and the temperature needed. Industrial electric heat supply .Choose measurement units 2. Enter the enclosure dimensions. 3. Enter your temperature variables 4. Choose mounting/unit option and show results. 5. SCE recommended units.

Our free Enclosure Cooling Calculator can help you determine heat load and find the right electrical cabinet cooling solution to meet your needs. Click to get started!

heat dissipation calculation for enclosure

Use this enclosure heat calculator to estimate temperature rise inside of an enclosure given dimensions and power load.By clicking on the part number, cooling performance (Qc) can be viewed graphically over the entire operating range from minimum to maximum voltage or current (Imin to Imax or Vmin to Vmax). V Op - displays the voltage corresponding to the operating current set at 75% Imax.

cnc tool holders manufacturers in ahmedabad

Use this calculator to help you decide: The required cooling or heating capacity of a temperature control product for your enclosure. Whether your enclosure cooling or heating needs will require an air conditioner, air to air heat exchanger, filtered fan.Follow the below steps to calculate Btu per hour: Determine the surface area of the enclosure (in square feet ) exposed to the air, ignoring the top of the cabinet. Determine the temperature differential (in degrees Farenheit) between maximum surrounding temperature and desired internal temperature. An Enclosure Heater Calculator assists in determining the required wattage for heaters in electrical and electronic enclosures. It is especially useful for engineers and technicians working in fields that require precise thermal management.

Heat generated by the components: W: Cooling power needed (for air conditioners) W: Air volume needed (for filter fans) m 3 /h: Heat to be supplied (for anticondensation heaters) WOur BTUH calculator estimates the number of BTUs to cool or heat an area based size, insulation, climate, and other factors. Use our BTUH Calculator now!Easily find the wattage needed to heat an enclosure (such as those for ATMs, sensors, gauges, etc.), by entering its dimensions and the temperature needed. Industrial electric heat supply made fast, simple, and accurate

fan enclosure size chart

Choose measurement units 2. Enter the enclosure dimensions. 3. Enter your temperature variables 4. Choose mounting/unit option and show results. 5. SCE recommended units. Our free Enclosure Cooling Calculator can help you determine heat load and find the right electrical cabinet cooling solution to meet your needs. Click to get started!

Use this enclosure heat calculator to estimate temperature rise inside of an enclosure given dimensions and power load.By clicking on the part number, cooling performance (Qc) can be viewed graphically over the entire operating range from minimum to maximum voltage or current (Imin to Imax or Vmin to Vmax). V Op - displays the voltage corresponding to the operating current set at 75% Imax.

Use this calculator to help you decide: The required cooling or heating capacity of a temperature control product for your enclosure. Whether your enclosure cooling or heating needs will require an air conditioner, air to air heat exchanger, filtered fan.

Follow the below steps to calculate Btu per hour: Determine the surface area of the enclosure (in square feet ) exposed to the air, ignoring the top of the cabinet. Determine the temperature differential (in degrees Farenheit) between maximum surrounding temperature and desired internal temperature. An Enclosure Heater Calculator assists in determining the required wattage for heaters in electrical and electronic enclosures. It is especially useful for engineers and technicians working in fields that require precise thermal management.

Heat generated by the components: W: Cooling power needed (for air conditioners) W: Air volume needed (for filter fans) m 3 /h: Heat to be supplied (for anticondensation heaters) WOur BTUH calculator estimates the number of BTUs to cool or heat an area based size, insulation, climate, and other factors. Use our BTUH Calculator now!

enclosure heater calculator

cnc torna taret dönmüyor

cnc torno programacion

How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

electrical enclosure heat calculator|enclosure heat load calculator