cnc machin dsighne CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made .

If the metal plug is being placed into a junction box, there is much less chance of coming into contact with an exposed energized part or wire. Terminology – Note that if searching on line a round metal plug is called a “steel hole plug.”

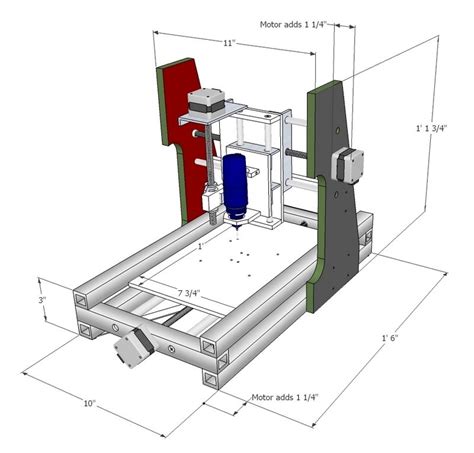

0 · small cnc machine wood projects

1 · free cnc projects for beginners

2 · free cnc patterns for wood

3 · cnc machine design pdf

4 · cnc machine design ideas

5 · cnc machine basic knowledge

6 · cnc design website

7 · best cnc projects for beginners

If the line cable enters in the switch box, a proper cable from a wall switch box to the ceiling fan box would have separate switched hots, black and red, for the fan and a light fixture. There would be two switches in the wall, one for the fan and one for the light.

In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material .In this complete guide to designing for CNC machining, we've compiled basic & . CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, .

It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different .

In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made . It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components.

Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining.

small cnc machine wood projects

The CNC (Computer Numerical Control) workflow is a systematic and highly precise process that transforms digital designs into physical objects through automated machining. What exactly is computer-numerical-controlled (CNC) machining? It’s a means to make parts by removing material via high-speed, precision robotic machines that use an array of cutting tools.

fanuc robodrill cnc milling machine

In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made . It’s an art form, requiring a keen eye for design and a deep understanding of the process. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance.

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines.

free cnc projects for beginners

Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components.Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining.

The CNC (Computer Numerical Control) workflow is a systematic and highly precise process that transforms digital designs into physical objects through automated machining.

free cnc patterns for wood

falcon eco nxt stainless steel lunch box

fap5002 universal processor unit junction box

I would place a pair of 3-pole splicing terminal blocks in the junction box. I would then run a pair of 3" conduit from the junction box to each service panel. The distance from the junction box to the service panels would be 4' and 5.5' respectively.

cnc machin dsighne|cnc machine basic knowledge