spot welding thin sheet metal Spot welding is a process that uses electricity to join two pieces of metal together. It’s a popular choice for joining sheet metal because it’s relatively quick and easy to do and creates strong bonds with minimal distortion. Transverse impact damages of 3D angle-interlock woven composites have been tested at split Hopkinson pressure bar along warp and weft directions respectively. The impact deformation and damages were photographed with a high-speed camera.Choose from a wide variety of Square, Rectangular, ECO-MESH®, and Designer Mesh types. Select either a Woven or Welded construction type for your design. Select the primary material .

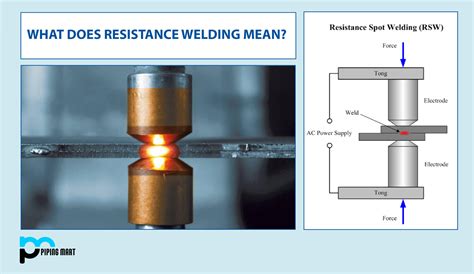

0 · what is resistance spot welding

1 · types of spot welding

2 · spot welding current and voltage

3 · spot welding current

4 · spot welding basics

5 · spot weld aluminum sheet metal

6 · how to spot weld 18galsheetmetal

7 · heat generated in spot welding

Discover high quality Sheet Metal & Body Panels parts and high performance accessories. Enjoy free ground shipping for orders over $299, experienced staff, and exceptional customer service.

I'm simply a self taught welder and thought I could pass on a tip that has helped me along the way. Pro welders probably spot wel. Spot welding is mostly used for thin plate welding, and the joint styles often adopt lap joints and flanged joints. There are many types of spot welding. We primarily use two types .

Spot welding is used to join electricity-conducting sheet metal and wire meshes. Its typically used to weld thin metals but thicknesses above 1 in. are possible only with specialized heavy-duty equipment.Spot welding automates sheet metal welding to ensure consistency without excessive heat spread. Conclusion. Welding thin sheet metal requires patience, precision, and an . Spot welding is a process that uses electricity to join two pieces of metal together. It’s a popular choice for joining sheet metal because it’s relatively quick and easy to do and creates strong bonds with minimal distortion. Welding a thin material like sheet metal to thicker metal surfaces can be somewhat of a headache, especially without taking the right approach to welding sheet metal. Below, you'll learn why ordinary welding techniques for thick steel won't work for fusing thinner metals and how you can avoid damaging or destroying work pieces by using the .

what is resistance spot welding

Weld metal that is too thick will cause you issues as well. To avoid these issues, you will want to weld thin sheet metal with flux core. Welding thin sheet metal with flux core is a great way to produce complex, detailed shapes . With high power and low-mode laser focusing, the resulting spot diameter is tiny, significantly promoting automation in thin sheet welding. Fast Welding Speed with Deep Penetration and Minimal Distortion: Due to the high . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

hidden electrical switch box

A spot welder works by passing an electric current through two thin pieces of metal. The resistance of the metal work pieces and the current passed though them creates enough heat to melt and join .I just did spot welding with a soldering gun on thin aluminum sheet metal using the copper tips provided. The secondary measures 1.0 volts AC so gives ~200 amps and the trigger can hold the current for 5 to 25 seconds of weld time. Beautiful! Cheap! MIG welding is widely utilized for welding thin metals. Follow these step-by-step instructions to successfully perform MIG welding on thin materials: . Ensure that you use very thin wires when welding with delicate, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0 . Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

types of spot welding

If the drill bit is too small, the weld may be weak, and if it is too large, it may remove too much material, weakening the structure. The size of the drill bit depends on the thickness of the metal sheets and the specific spot welding technique used. For thin sheet metal, the recommended drill bit size is typically around 1/8 inch (3.175 mm). Skip Welding Technique. When welding thin sheet metal, do not try to run one bead right across the joint. This will cause too much heat to build up. Instead, run a series of short welds at different points in the metal that eventually join together. Leave the metal to cool for a second or two between welds to help the heat dissipate. Welding sheet metal with a stick welder is a bit more challenging, especially when welding thin sheets of metal. The heat input in stick welding is generally . MIG, MAG, and Resistance Spot welding. Most recently as a Process Engineer for Laser and TIG welding processes. To address some of the questions I frequently got asked or was wondering .

The spot welding process is one of the oldest welding methods used. Its primary usage is in welding auto body and sheet metal. Spot welding is usually used to join a panel of overlapping sheet metal, parts that are usually 3mm thick. . Welding autobody panels. Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. Welding nearly always causes some distortion: the metal in and around the weld shrinks as it cools, and this shrinking often upsets the shape of the metal.

Spot welding is mostly used for thin plate welding, and the joint styles often adopt lap joints and flanged joints. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these . Hi to everyone I'm new to welding end the forum looking for advise I want to by welder mainly for thin sheet metal and bodywork I'm looking at few options can you give your advice and opinion Lincoln Power Mig 180C ; Lincoln Electric Powertec 191c Mig Welder ;Millermatic 180 and Portamig 185 your opinion is appreciated thanks

Mig Welding Thin Sheet Metal. Mig welding is a popular and straightforward method of welding thin sheet metal. For mig welding, you don’t need much in the way of equipment. You will only need a mig welder and a .

The first technique is spot welding, this is a resistance based welding method wherein two copper electrodes are connected to the sheet metals. Due to the resistance of the base metal, heat is generated when an electric current and .

Spot Welding. Also known as resistance welding, spot welding involves compressing two pieces of sheet metal and applying pressure and heat from copper electrodes to create a nugget of weld that connects the pieces. Spot welding is often confused with tack welding, which also uses a small amount of weld to attach two pieces.

Techniques for MIG welding thin sheet metal. MIG welding thin sheet metal requires specific techniques to ensure a successful weld. Here are some tips to help you achieve high-quality welds: Maintain a short arc length: Keep the arc length as short as possible without touching the metal. A shorter arc length helps to minimize heat input and .But first, can you spot weld aluminum? Technically speaking, spot welding 100% pure aluminum is nearly impossible. A thin layer of aluminum oxide forms on the surface of the aluminum. This layer has a very high electrical resistance. Since spot welding relies on resistance heating, the layer of aluminum oxide makes it almost impossible. Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Common Mistakes to Avoid in Butt Welding Sheet Metal. While butt welding sheet metal is a valuable and versatile technique, it is not without its challenges and potential pitfalls. Understanding and avoiding common mistakes in the butt welding process is essential for achieving superior weld quality, structural integrity, and overall project .

hidden key electrical box

An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo. playing around with a new spot welder I bought and dug out a old spot welder and got it up and working. want these spot welders for some future projects and.

Spot welding automates sheet metal welding to ensure consistency without excessive heat spread. Conclusion. Welding thin sheet metal requires patience, precision, and an understanding of the material properties. We are proud to have mastered these challenges at Shengen and pushed the limits of sheet metal fabrication. Our commitment to .

This method is widely used in the automotive industry for joining thin metal sheets. Both plug welding vs spot welding have their unique advantages and disadvantages, and understanding these nuances is crucial for making informed decisions in metalworking projects. Differences Between Plug Weld vs Spot Weld Technique and EquipmentUsing a spot welder can vary between different machines, however the below can be used as a simple guide to get you started: Setting up the spot welder: Adjust the welding parameters on the spot welder, including welding current, welding time, and electrode pressure, based on the material thickness, type of metal, and desired weld quality.Consult the manual or welding .

spot welding current and voltage

hidden junction box in wall

hide di2 junction box

Keep your bread fresh and your cats out with this sleek stainless steel bread box with a roll-top lid and ventilation holes. Our top-of-the-line bread bin, inspired by classic bakery bread boxes. This countertop bread bin is a stylish and pract.

spot welding thin sheet metal|what is resistance spot welding