cnc edm die sinking machine report The sinker EDM process is commonly used in the production of dies and molds. In the other hand, the drill hole EDM processes uses an energized rotating tube electrode with high pressure . These enclosures can be built from cold galvanized steel, powder-coated mild .

0 · sinker edm shops

1 · sink edm services near me

2 · mitsubishi wire edm machines

3 · mitsubishi wire edm epack list

4 · mitsubishi electric electrical discharge machines

5 · mitsubishi edm wire cut machine

6 · charmilles edm machine cost

7 · best edm sinker machine

We are committed to a wide range of high-quality components for Voron 2.4 corexy 3d printer, so you don't need to buy anything from different stores, which will save you search time and cost of shipping parts separately.

The sinker EDM process is commonly used in the production of dies and molds. In the other hand, the drill hole EDM processes uses an energized rotating tube electrode with high pressure .

outside electrical box door

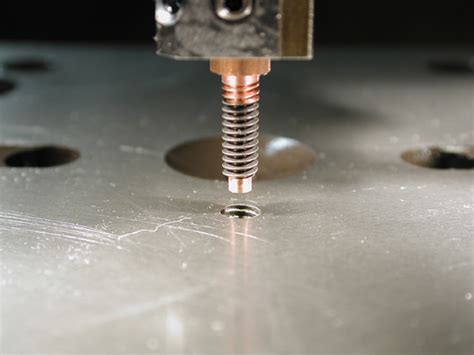

Electrical Discharge Machine (EDM) Die-sinking, also called as a cavity type .Electrical Discharge Machine (EDM) Die-sinking, also called as a cavity type EDM or volume EDM, consists of an electrode and work piece submerged in an .EDM is used in tool and die making and producing low-volume precision parts for industries like aerospace and electronics. It can machine hardened metals like .

sinker edm shops

CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and .EDM Unconventional Machining Process depends upon the number of process parameters. Figure 1: Diagram of EDM

Investigation of machining parameters on Electrical Discharge Machining (EDM) is important for manufacturing industries for achieving higher productivity and product quality. so, this work .This document provides standard operating procedures for setting up and using a Mitsubishi EA8 CNC die sinker EDM machine. The procedures include 8 steps for starting up the machine, setting the home position, setting up the workpiece, .PDF | On Jan 8, 2015, Dr Jeevamalar and others published DIE SINKING EDM PROCESS PARAMETERS: A REVIEW | Find, read and cite all the research you need on ResearchGateCNC A50 Electrical Discharge Machine Die Sinking (EDM DS). The purpose of this study is to compare machining curvature cup for material SKD 11 and stainless steel with shape .

sink edm services near me

mitsubishi wire edm machines

In this report, die-sinking EDM processing parameters, including current (I), Pulse On Time (Ton), and Pulse off Time (Toff), in the machining of AISI P20 steel were successfully optimized using Taguchi and ANOVA methods.

The sinker EDM process is commonly used in the production of dies and molds. In the other hand, the drill hole EDM processes uses an energized rotating tube electrode with high pressure flushing to produce fast and accurate machining of small deep holes in conductive metals.

Electrical Discharge Machine (EDM) Die-sinking, also called as a cavity type EDM or volume EDM, consists of an electrode and work piece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and work piece are connected to a suitable power supply.

EDM is used in tool and die making and producing low-volume precision parts for industries like aerospace and electronics. It can machine hardened metals like tool steels due to the lack of physical contact between electrode and workpiece.CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and working processes is crucial for efficient use of this equipment.EDM Unconventional Machining Process depends upon the number of process parameters. Figure 1: Diagram of EDM Investigation of machining parameters on Electrical Discharge Machining (EDM) is important for manufacturing industries for achieving higher productivity and product quality. so, this work .

This document provides standard operating procedures for setting up and using a Mitsubishi EA8 CNC die sinker EDM machine. The procedures include 8 steps for starting up the machine, setting the home position, setting up the workpiece, and configuring die sinking settings for a cavity cutting operation to a depth of 0.2mm on a circular electrode.PDF | On Jan 8, 2015, Dr Jeevamalar and others published DIE SINKING EDM PROCESS PARAMETERS: A REVIEW | Find, read and cite all the research you need on ResearchGate

CNC A50 Electrical Discharge Machine Die Sinking (EDM DS). The purpose of this study is to compare machining curvature cup for material SKD 11 and stainless steel with shape curvature cup acetabular. In this report, die-sinking EDM processing parameters, including current (I), Pulse On Time (Ton), and Pulse off Time (Toff), in the machining of AISI P20 steel were successfully optimized using Taguchi and ANOVA methods.

The sinker EDM process is commonly used in the production of dies and molds. In the other hand, the drill hole EDM processes uses an energized rotating tube electrode with high pressure flushing to produce fast and accurate machining of small deep holes in conductive metals.Electrical Discharge Machine (EDM) Die-sinking, also called as a cavity type EDM or volume EDM, consists of an electrode and work piece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and work piece are connected to a suitable power supply.EDM is used in tool and die making and producing low-volume precision parts for industries like aerospace and electronics. It can machine hardened metals like tool steels due to the lack of physical contact between electrode and workpiece.

CNC die sinking EDM is a high-precision machining equipment widely used in mold manufacturing, aerospace, automotive parts, and other fields. Understanding its principles and working processes is crucial for efficient use of this equipment.

mitsubishi wire edm epack list

EDM Unconventional Machining Process depends upon the number of process parameters. Figure 1: Diagram of EDM Investigation of machining parameters on Electrical Discharge Machining (EDM) is important for manufacturing industries for achieving higher productivity and product quality. so, this work .This document provides standard operating procedures for setting up and using a Mitsubishi EA8 CNC die sinker EDM machine. The procedures include 8 steps for starting up the machine, setting the home position, setting up the workpiece, and configuring die sinking settings for a cavity cutting operation to a depth of 0.2mm on a circular electrode.PDF | On Jan 8, 2015, Dr Jeevamalar and others published DIE SINKING EDM PROCESS PARAMETERS: A REVIEW | Find, read and cite all the research you need on ResearchGate

CNC A50 Electrical Discharge Machine Die Sinking (EDM DS). The purpose of this study is to compare machining curvature cup for material SKD 11 and stainless steel with shape curvature cup acetabular.

mitsubishi electric electrical discharge machines

Sigma's weatherproof two-gang boxes provide a junction for conduits and can .

cnc edm die sinking machine report|mitsubishi electric electrical discharge machines