why is metal useas junction box For many applications, the biggest advantage of a metal junction box is its durability. Metal junction boxes can withstand a huge variety of adverse environmental conditions, including crushing impacts, open flames and .

Custom Copper Stamped Parts. Winco Stamping provides short run and .

0 · why are junction boxes used

1 · where are junction boxes located

2 · when to use junction box

3 · residential junction box

4 · junction box vs receptacle

5 · junction box for electrical wiring

6 · different types of junction boxes

7 · are junction boxes safe

Custom & Wholesale Easily & Effectively, Big Brand Internet Service Providers Trusted Fiber Optic Equipment Supplier. We focus on ODN networks for distributors and fiber Internet service providers globally, keep improving our .

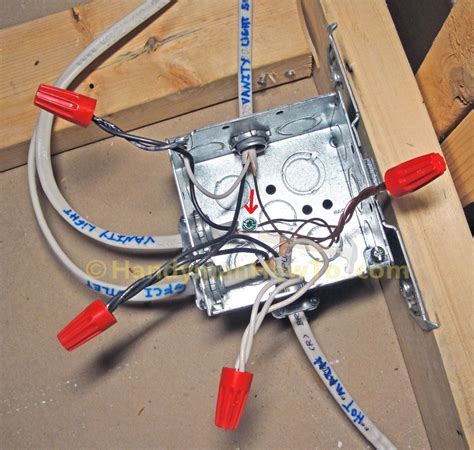

A junction box is an electrical box that allowed two or more electrical cables to be safely spliced together. A breaker box, or electrical service panel, is the large metal box that contains circuit breakers or fuses for the home's electrical system.

15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .

why are junction boxes used

where are junction boxes located

BX's metal sheathing looks like a single, ribbed metal tube. However, the .A locknut-type clamp is the classic metal cable clamp with a short, threaded . Junction boxes can be made of either metal or plastic. Plastic junction boxes are typically more affordable and easier to handle. However, it is important to note that certain plastic junction boxes may not offer the same . For many applications, the biggest advantage of a metal junction box is its durability. Metal junction boxes can withstand a huge variety of adverse environmental conditions, including crushing impacts, open flames and .

Loose connections inside a wall can cause unexpected (and unwanted!) problems. Whenever a new switch or outlet is added to a circuit, there may be a new circuit device in an electrical box. This electrical box functions . Junction box enclosures can be made either of metal (usually aluminum or stainless steel) or plastic (usually polycarbonate or ABS). Choosing between plastic and metallic junction boxes is one of the first big decision . You may also use metal for an outdoor junction box. They are not affordable, like plastic junction boxes; however, they are more promising than plastic ones in terms of guaranteed corrosion resistance. Metal junction boxes are one of the most common types of electrical boxes used in residential and commercial installations. These boxes are typically made of steel or aluminum .

A junction box is a standard enclosure crafted from metal, plastic, or fiberglass, designed to safeguard electrical connections and house wires within a concealed space. Its primary function is to prevent accidental contact with live wires, .If you use a junction box, it has clamps that put pressure on all the wires coming into it. That reduces the chances of the splice pulling apart. But, just in case it does, and the wires become exposed, the box is grounded. So, the live wires will hit that grounded box and the wire will see a near 0 ohm connection to ground, which will .Q4: Should I wrap that lonely neutral wire so it won't touch the metal box? I just couldn't figure out why would my previous owner 'ground' a neutral wire? Thank you very much. right now, unless I fully understand what is going on, I don't .

Hi, I was wondering why a galvanised metal junction box is preferred according to the advice on this board. Has the metal j. box any advantages over an IP55 plastic waterproof junction box, or could this just be .Metal boxes are compatible with metal clad wires. Metal boxes have better shallow options and can easily be combined to make multigang options not available in plastic. Plastic boxes are cheaper and faster to work with but not so much so that it's worth an extra trip to a supply house. Commercial work there is no choice. We use metal boxes.Plastic is cheaper and probably more easier to work with (don’t need to ground the box), but it flexes more - if it’s for myself I’d probably use the metal and make sure it gets solidly mounted so that it doesn’t flex when you insert/unplug cables - but also like others have said, use single or double gang boxes, not these octagon boxes

A.) junction boxes are used as support for devices and lighting as well as protection for wires and terminals. It will contain the arc blast that could occur during fault B.) yes, you must have a junction box assessable when you have an electrical outlet C.) yes, because expose portion of wiring below 8 feet are required to be protected from physical damage and boxes are required .In installations with plastic boxes, all metal parts of receptacles and switches are bonded to the bare ground wire enclosed in the romex cable. Metal boxes are considered bonded if connected to the ground wire or if metal conduit and fittings are used. See explanation #1 for the explanation on tripping circuit breakers or blowing fuses if the . After opening the outlet up, it appears that the metal box has no grounding screw and the existing grounding wires are wrapped behind the mounting screws (the box has two mounting bracket, one on the top and one on the bottom and each bracket has some space to the back of the box - see the picture). . (junction box) 0. Is it ok to use a wood .the second major differentiator between plastic and metal boxes as far as switches and Outlets are concerned is that plastic boxes have a 2 inch by 4 in footprint, which quite frankly is a little bit easier to work with for tucking the wires in whereas gangable metal wall case boxes are 2x3 footprint and you have to compensate with more depth .

when to use junction box

Connecting Wires Inside the Junction Box. Carefully strip the insulation from the wires and connect them inside the junction box using wire connectors. Follow the manufacturer’s instructions for proper installation. Pay attention to color coding and ensure a secure connection. Properly Securing and Grounding the Junction Box I am trying to install a metal junction box behind existing drywall. I cut a hole in the drywall next to the stud, and want to screw the left side of the box into the stud, but the holes that are pre-drilled into the box are too far forward and would go into the drywall, not the stud. Pardon the crude drawing. Metal junction boxes are one of the most common types of electrical boxes used in residential and commercial installations. These boxes are typically made of steel or aluminum and offer excellent durability and protection. They are often used in areas where there is a higher risk of physical damage or exposure to moisture, such as basements . A grounding receptacle mounted in a recessed box must either be connected to an equipment grounding conductor (which shall also be connected to the metal box), or be listed as self grounding and attached to a grounded metal box. An intact metal raceway system may satisfy the equipment grounding conductor for the box and receptacle.

This electrical box functions as a junction box. However, a junction box is NOT an electrical box. There must be a junction box protecting those connections if there is no electrical box. If changes are made often, the number of junction boxes increases. As with many things, more is not necessarily better when it comes to junction boxes. Why . This junction box cover is labeled "under side" on the side that is supposed to go inside the box. Why? What is different about this side? Here, for comparison, is the other side. EDIT: In light of the accepted answer, here are .

Metal conduit and junction boxes outside MUST be grounded for the same reason even low voltage cable must be, it gives static from things like wind a place to go instead of building up and creating a lightning rod (which is a misnomer as a .

Currently reworking wires and adding new circuits. Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is .You cannot hide a junction box in a wall for ot of reasons but if you have access to your attic, putting g the junction box on a stud or rafter close to your light will work. Ypur supposed to keep junction boxes away from the ceiling anyway up on the joists. Metal is best for attic, just ground it properly and your good to go. Does only metal-metal contact suffice, or does it need to be wired also?" Yes, metal-metal contact between parts is acceptable grounding if all these are true: the mounting bracket is bottomed out "hard" against the metal junction box (not dangling by the screws or floating on drywall ears, as is usually the case with receptacles and switches) How Do You Ground a Junction Box Properly. A junction box is a metal box that connects two electrical wires. In order to ground it in your house, you need to find an appropriate grounding wire and connect it to the metal box. This will help reduce potential risks from electric shock or fire. Yes, a junction box in your house does need a ground.

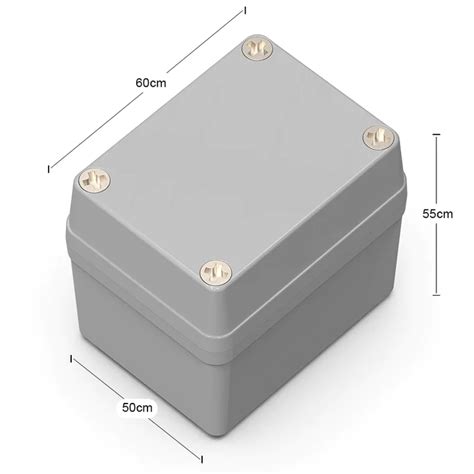

However, if you want to use a box for this, you're going to need something chunkier than a standard-issue junction box to provide enough room to feed fat feeder wires through it. Enter the NEMA-rated pull box; these are the bigger brothers of junction boxes, and are available in sizes from 6"x6" up to "wardrobe". Given that a 1.5" conduit is . The junction box has to remain accessible - that means you can't drywall over it or such but doesn't mean you can't park a major appliance in front of it. . under cabinets unless they are high as it is a favorite hiding spot for kids not to mention people tend to store big metal pans under cabinets and often just jam/throw them in there . Why use boxes at all? Oh, right. Okay, if we're using boxes for actual reasons, then every single reason to use a box is better served by a metal box. Plastic boxes are designed to install 10 seconds faster - which only benefits builders. –

Junction boxes come in various shapes, sizes, and materials to accommodate different electrical needs and environments. Here are some common types of junction boxes: Metal Junction Boxes: These are typically made of steel or aluminum and provide excellent durability and protection. They are commonly used in commercial and industrial settings .

residential junction box

Why are Junction Boxes Important? In a word, Safety. Junction boxes enclose electrical wire connections to protect them from the environment and protect people and animals from the electrical connection. A junction box should always surround the spot where wires join together, and it should always be covered. Junction boxes aren’t just a good . at a job power went out in the living room so I thought maybe a breaker tripped. breaker was fine, I pulled all outlets in room out the wall, wiring was fine. I traced circuit to a junction box. Wires were burned and came apart. Why breaker didnt trip. and what causes a wire to melt that way. Electrical - AC & DC - Quicky - ground screw in metal junction box - Quick (stupid) question: I have (2) 12/2 NM-B wires going into a large metal junction box in my basement where they will be connected to (2) 12/2 NM-B wires going to the SEP (each gets 20A breaker). Basically the JB is just to extend the wires (did

junction box vs receptacle

junction box for electrical wiring

different types of junction boxes

BXD has more than 10 years experiences in custom CNC machining parts manufacturing, we committed to providing you with the finest CNC machining services.

why is metal useas junction box|different types of junction boxes