bending stainless steel sheet metal This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

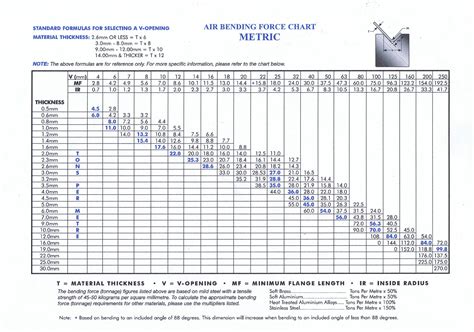

0 · stainless steel cold bending chart

1 · stainless steel bend chart

2 · does stainless steel bend easily

3 · best stainless steel for bending

4 · bending stainless steel flat bar

5 · bending sheet metal by hand

6 · bending sheet metal at home

7 · bending 304 stainless steel sheet

Generally, straight punches refer to those mechanical devices that are used to cut through metal sheets or other material sheet sheets, such as leather or plastic, to give an even surface. These types of punches are available in numerous leather and plastic industries and are quite easy to use.

Discover the secrets of bending stainless steel by diving into the world of metalwork. Bending stainless steel involves understanding its properties, using the right tools, and applying precise techniques. Methods like heat bending, . The most common bending techniques for stainless steel sheet include manual bending, mechanical bending, and heat bending. Manual bending involves using hand tools such as a vise or hammer to bend the sheet into the .This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .

Discover the secrets of bending stainless steel by diving into the world of metalwork. Bending stainless steel involves understanding its properties, using the right tools, and applying precise techniques. Methods like heat bending, cold bending, and using a press brake are standard. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. The most common bending techniques for stainless steel sheet include manual bending, mechanical bending, and heat bending. Manual bending involves using hand tools such as a vise or hammer to bend the sheet into the desired shape.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

There are numerous ways to bend steel sheets, providing precise and efficient results. Let’s discuss some of these methods of bending stainless steel. Hopefully, it will give you more clarity and enable you to choose the ideal method for your manufacturing process. Give you a guide to bending machine molds. 1. V-Bending. Understanding the basics of sheet metal bending and choosing the right tools and techniques is crucial for achieving the desired results. Consider the material properties, bending technique, and design considerations when bending stainless steel sheets. Get the key points and analysis you need to bend stainless steel like a pro! Learn how to avoid springback and get flawless results. Get expert tips now. Bending stainless steel sheet requires specific tools and techniques. Understanding the properties of stainless steel is crucial for successful bending. Clean and prepare the sheet before bending to avoid issues. Choosing the right bending method is .

“Bending stainless steel sheets is beneficial when parts need to be brought to market quickly. It usually results in less material wastage during part manufacturing.” Stainless steel is among the most preferred materials for custom tube bending because of its high strength and corrosion resistance. Bending stainless steel sheets is a fundamental skill required in various industries, ranging from architecture to manufacturing. In this comprehensive guide, we'll delve into the techniques, tools, and best practices necessary to bend stainless steel .

Discover the secrets of bending stainless steel by diving into the world of metalwork. Bending stainless steel involves understanding its properties, using the right tools, and applying precise techniques. Methods like heat bending, cold bending, and using a press brake are standard. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. The most common bending techniques for stainless steel sheet include manual bending, mechanical bending, and heat bending. Manual bending involves using hand tools such as a vise or hammer to bend the sheet into the desired shape.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.There are numerous ways to bend steel sheets, providing precise and efficient results. Let’s discuss some of these methods of bending stainless steel. Hopefully, it will give you more clarity and enable you to choose the ideal method for your manufacturing process. Give you a guide to bending machine molds. 1. V-Bending. Understanding the basics of sheet metal bending and choosing the right tools and techniques is crucial for achieving the desired results. Consider the material properties, bending technique, and design considerations when bending stainless steel sheets.

Get the key points and analysis you need to bend stainless steel like a pro! Learn how to avoid springback and get flawless results. Get expert tips now.

Bending stainless steel sheet requires specific tools and techniques. Understanding the properties of stainless steel is crucial for successful bending. Clean and prepare the sheet before bending to avoid issues. Choosing the right bending method is . “Bending stainless steel sheets is beneficial when parts need to be brought to market quickly. It usually results in less material wastage during part manufacturing.” Stainless steel is among the most preferred materials for custom tube bending because of its high strength and corrosion resistance.

junction box eaves

stainless steel cold bending chart

stainless steel bend chart

$41.14

bending stainless steel sheet metal|stainless steel bend chart