bending metal for old house Before you can install the fascia, you first need to cut and bend the aluminum to fit. Start with the eaves fascia, cutting and bending as many sections of aluminum flashing as you need to cover it. eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and Turning, Sheet Metal Fabrication, Injection Molding, and dozens of materials.

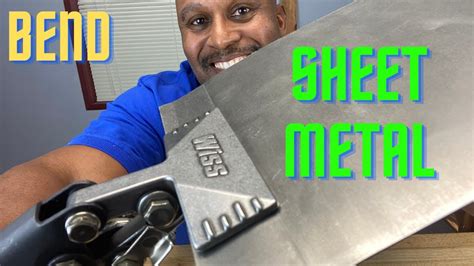

0 · folding sheet metal at home

1 · bending sheet metal by hand

2 · bending 18 gauge sheet metal

3 · bending 16 gauge sheet metal

4 · bend thick metal without tools

5 · bend sheet metal without brake

6 · bend metal without expensive tools

7 · bend metal without a brake

Goliath Parts offers custom-machined parts at competitive prices for any industry or sector. All these parts are built strong & made in the USA. Get a quote now!

Before you can install the fascia, you first need to cut and bend the aluminum to fit. Start with the eaves fascia, cutting and bending as many sections of aluminum flashing as you need to cover it.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal . Use a marker to indicate where you want to make the bend on the sheet metal. 2. With the bend line along the edge, mount the sheet between two angle irons or two robust .

Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for . Heat application in metal tube bending consists of controlled heating of the metal to make it more supple. Usually, a torch or induction heater is employed to put heat on the area .

Metal brake: You’ll use a metal brake to bend the aluminum flashing to the required angles. If you don’t have one, you can rent it from most hardware stores or use a homemade bending jig. We also recommend having .Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. A metal brake is the tool for bending custom metal flashing and decorative trim. Every siding contractor and most roofers have one. But a brake can come in handy for all sorts of projects.

Before you can install the fascia, you first need to cut and bend the aluminum to fit. Start with the eaves fascia, cutting and bending as many sections of aluminum flashing as you need to cover it.

To think about bending a sheet of metal that has appreciable thickness, focus on an imaginary central sheet, the so-called neutral line or neutral axis, within the thickness. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Use a marker to indicate where you want to make the bend on the sheet metal. 2. With the bend line along the edge, mount the sheet between two angle irons or two robust wooden boards. 3. As more of the metal gets exposed through bending, use either a rubber mallet or a hammer with a wooden block to pull the metal upwards until the bend is there. 4.

Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for successful sheet metal bending. . you do not need to control the tonnage as precisely. So, even old, and not-so-accurate punches and press brakes can be used .

Heat application in metal tube bending consists of controlled heating of the metal to make it more supple. Usually, a torch or induction heater is employed to put heat on the area to be bent. Heating the metal improves its flexibility and makes achieving a smoother radius possible, especially with tighter bends or thicker tubing when the metal . Metal brake: You’ll use a metal brake to bend the aluminum flashing to the required angles. If you don’t have one, you can rent it from most hardware stores or use a homemade bending jig. We also recommend having exterior-grade caulk, a hammer, a measuring tape, a utility knife, and some scrap wood on hand.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

A metal brake is the tool for bending custom metal flashing and decorative trim. Every siding contractor and most roofers have one. But a brake can come in handy for all sorts of projects.Before you can install the fascia, you first need to cut and bend the aluminum to fit. Start with the eaves fascia, cutting and bending as many sections of aluminum flashing as you need to cover it. To think about bending a sheet of metal that has appreciable thickness, focus on an imaginary central sheet, the so-called neutral line or neutral axis, within the thickness.

how many volt should outside electrical box be

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. Use a marker to indicate where you want to make the bend on the sheet metal. 2. With the bend line along the edge, mount the sheet between two angle irons or two robust wooden boards. 3. As more of the metal gets exposed through bending, use either a rubber mallet or a hammer with a wooden block to pull the metal upwards until the bend is there. 4.Learn essential custom sheet metal bending techniques and tips for designing and producing high-quality metal parts. Discover best practices, design guidelines, and practical advice for successful sheet metal bending. . you do not need to control the tonnage as precisely. So, even old, and not-so-accurate punches and press brakes can be used . Heat application in metal tube bending consists of controlled heating of the metal to make it more supple. Usually, a torch or induction heater is employed to put heat on the area to be bent. Heating the metal improves its flexibility and makes achieving a smoother radius possible, especially with tighter bends or thicker tubing when the metal .

Metal brake: You’ll use a metal brake to bend the aluminum flashing to the required angles. If you don’t have one, you can rent it from most hardware stores or use a homemade bending jig. We also recommend having exterior-grade caulk, a hammer, a measuring tape, a utility knife, and some scrap wood on hand.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.

folding sheet metal at home

Boly manufactures and supplies a variety of custom CNC aluminum machined parts, offering aluminum machining services. We have advanced CNC turn & mill machines and surface treatment technology to provide one-stop machining solutions.

bending metal for old house|bending 16 gauge sheet metal