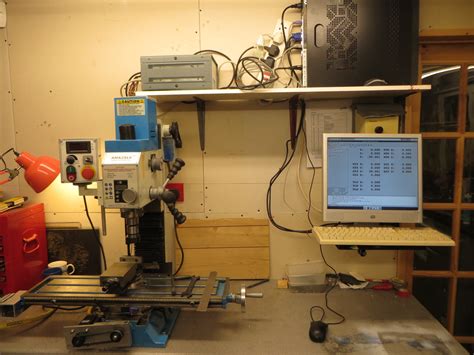

amadeal milling machine cnc conversion I recently bought the same AMA25LV and I am in the process of converting the mill to cnc. I'm also starting a conversion on a AMA25 as well.. Any pics and information would be great. Looks good so far. Best all round mill/router? Vertical mill or gantry router? Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

0 · CONVERSION: Amadeal25LV CNC Conversion

1 · CONVERSION: Amadeal AMA 25LV Mill to CNC

2 · CNC conversion AMAT25LV AMAT30LV WM18 advice needed

A metal sheet is no different than a rectangular bar, it is in the steel weight calculator for your convenience mostly. The formula used to compute the weight is exactly the same. See more

I recently bought the same AMA25LV and I am in the process of converting the mill to cnc. I'm also starting a conversion on a AMA25 as well.. Any pics and information would be .

My mill is about 3 years old and used mainly for making clock parts, the reason for converting to CNC is to speed up the cutting out of clock wheel's and plates and to move away from cutting .

CONVERSION: Amadeal25LV CNC Conversion

CONVERSION: Amadeal AMA 25LV Mill to CNC

Hi Guys, along with designing a cnc router I am also looking to buy a milling machine. I will use it manually prior to a CNC conversion. I have limited space in my garage so . I recently bought the same AMA25LV and I am in the process of converting the mill to cnc. I'm also starting a conversion on a AMA25 as well.. Any pics and information would be great. Looks good so far. Best all round mill/router? Vertical mill or gantry router?My mill is about 3 years old and used mainly for making clock parts, the reason for converting to CNC is to speed up the cutting out of clock wheel's and plates and to move away from cutting by hand with a fretsaw. Hi Guys, along with designing a cnc router I am also looking to buy a milling machine. I will use it manually prior to a CNC conversion. I have limited space in my garage so the max sizes are the WM18 /AMAT25 /AMAT30LV size.

The Nema 23 stepper motor is elegantly installed in the top of the machine, directly linked to the Z axis ball screw. This installation has superior accuracy over other conversion plans. Even better, it doesn't take any extra space on the back of the mill.Our range of machinery and equipment covers mini-lathe lathes, milling machines, vices, CNC, Gears, Motor Clamping Collet, cutting, metalworking, metal turning, rotary, airbrush, air compressors and bandsaws.VM35 (L) is ball-screw type based on VM32 (L), wiith X, Y and Z axis ball screw. 11. VM35 (L) is your best choice for CNC updating conversion. The machine was a lathe/mill combo, and wasn't a good mill at all, but was an OK lathe. My cross slide was converted using an 8mm ball screw. The problem is not the screw, but the nut.

Recently I have decided to convert my Amadeal AMA16 milling machine to CNC. I just put it together a day ago and as I was setting it up in Mach3 I ran into an interesting problem. (I'm novice when it comes to CNC machining so it might be a simple fix but I . As I now check the Amadeal website it seems that a lot of their machines have a 25 designation but not always a lot of dimensions , so easy to presume it would be comparable to Sieg SX25, Sealey SM 25 etc. You have to tell the CNC program how many pulses to send out to the steppers to move a distance. The x and y should be exactly the same as they both have the same ballscrew pitch and are both directly connected to the steppers. The z axis has a reduction pulley and belt so that s slightly different.

I recently bought the same AMA25LV and I am in the process of converting the mill to cnc. I'm also starting a conversion on a AMA25 as well.. Any pics and information would be great. Looks good so far. Best all round mill/router? Vertical mill or gantry router?My mill is about 3 years old and used mainly for making clock parts, the reason for converting to CNC is to speed up the cutting out of clock wheel's and plates and to move away from cutting by hand with a fretsaw. Hi Guys, along with designing a cnc router I am also looking to buy a milling machine. I will use it manually prior to a CNC conversion. I have limited space in my garage so the max sizes are the WM18 /AMAT25 /AMAT30LV size.

The Nema 23 stepper motor is elegantly installed in the top of the machine, directly linked to the Z axis ball screw. This installation has superior accuracy over other conversion plans. Even better, it doesn't take any extra space on the back of the mill.Our range of machinery and equipment covers mini-lathe lathes, milling machines, vices, CNC, Gears, Motor Clamping Collet, cutting, metalworking, metal turning, rotary, airbrush, air compressors and bandsaws.VM35 (L) is ball-screw type based on VM32 (L), wiith X, Y and Z axis ball screw. 11. VM35 (L) is your best choice for CNC updating conversion. The machine was a lathe/mill combo, and wasn't a good mill at all, but was an OK lathe. My cross slide was converted using an 8mm ball screw. The problem is not the screw, but the nut.

CNC conversion AMAT25LV AMAT30LV WM18 advice needed

Recently I have decided to convert my Amadeal AMA16 milling machine to CNC. I just put it together a day ago and as I was setting it up in Mach3 I ran into an interesting problem. (I'm novice when it comes to CNC machining so it might be a simple fix but I . As I now check the Amadeal website it seems that a lot of their machines have a 25 designation but not always a lot of dimensions , so easy to presume it would be comparable to Sieg SX25, Sealey SM 25 etc.

Oxy-acetylene welding and brazing are two techniques commonly used for joining metal materials. Although they may seem similar, there are significant differences between the two. Understanding these differences is crucial to achieve the desired results.

amadeal milling machine cnc conversion|CNC conversion AMAT25LV AMAT30LV WM18 advice needed