sheet metal products in demand Amid these exciting developments, the metal sheets industry's prospects certainly look as sturdy and promising as the products they deliver. The impact of these constant dynamics of global supply and demand on the metal sheet industry is indeed a fascinating cut and bend of this ever-evolving market. Yes, the low cost of operation is the leading reason for MIG welding with straight CO2, also called C100. But how big is the difference when compared to a 75% Argon/25% CO2 blend? Also known as C25, it’s considered the best all-around gas blend for MIG welding on mild steel. Here’s a chart comparing two popular sizes side-by-side.

0 · sheet steel market size

1 · sheet metal market trends

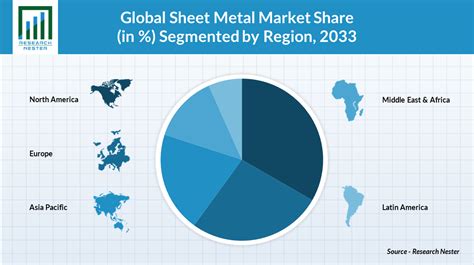

2 · sheet metal market share

3 · sheet metal market outlook

4 · sheet metal market growth

5 · sheet metal manufacturing trends

6 · sheet metal industry news

7 · sheet metal industry

Check out our western electric box selection for the very best in unique or custom, handmade pieces from our jewelry boxes shops.

With the increasing focus on environmental sustainability and renewable energy sources, there is growing demand for sheet metal products in solar panel mounting systems, wind turbine .

1957 chevy wagon sheet metal

On-Demand Sheet Metal Fabrication, Custom CNC Machining, and Advanced 3D Printing Capabilities. Leading digital manufacturer of sheet metal, CNC machining, 3D printing with immense capacity in the United States, Germany, .Discover how Sheet Metal Products can become your go to contract manufacturer. With our 105,000 square foot facility and over 25 different processes available there is no job too big or too small for us. With our experience we will find a solution to all your manufacturing needs. The first step to a stress free supply chain is just a click away.Amid these exciting developments, the metal sheets industry's prospects certainly look as sturdy and promising as the products they deliver. The impact of these constant dynamics of global supply and demand on the metal sheet industry is indeed a fascinating cut and bend of this ever-evolving market.

sheet steel market size

Suzhou First Sheet Metal Products Co.,Ltd founded in 2002, it is a private enterprise specializing in sheet metal processing. The company is located in Qutang Town, Xiangcheng District, Suzhou. It covers an area of 55,000 square meters, has a factory building of about 40,000 square meters, and an office building of about 5,500 square meters.For example, perforated sheet iron that is made on the basis of aluminum sheets or steel galvanized sheets is a high-demand raw material in the construction sphere and machine production. . The production of different flat and large .

Although sheet metal products’ diverse applications offer stability, weak demand and increased competition from imports and low-cost substitutes have harmed revenue and profitability. Rising commercial and industrial construction activity has boosted . Explore the cutting-edge world of sheet metal fabrication as we unveil the key trends shaping the industry in 2024.Stay ahead with our in-depth analysis. . Consumer preferences are evolving towards personalized and customized products. To meet this demand, manufacturers are leveraging advanced digital tools for design and production. Computer . “Agricultural spending is also accelerating,” Kuehl said, “as global food demand creates significant growth potential for commercial farms.” Fabricated Metal Products Takes an Upward Turn. The trend lines in metal fabrication reflect an average that, at the individual company level, is highly dependent on a shop’s customer mix.Metal stamping is an assembly process employed to transform flat metal into desired shapes. In the automotive industry, a specific form of metal stamping known as automotive stamping is utilized to manufacture large quantities of sheet metal parts for both aftermarket and original equipment manufacturer (OEM) markets. This industry produces a .

sheet metal market trends

sheet metal market share

Question 1). Positively Rivet Inc. is a small machine shop that produces sheet metal products. It had one line dedicated to the manufacture of light-duty vent hood shells, but because of strong demand it recently added a second line. The new line makes use of higher-capacity automated equipment but consists of the same basic four processes as the old line.

Sheet Metal Trades Workers play a pivotal role in shaping the nation’s infrastructure. These skilled professionals are one of the people behind the construction and manufacturing sectors, meticulously crafting products and components from sheet metal and other materials.. From the towering skyscrapers in Sydney to the intricate machinery in Melbourne’s .

We work on the forefront of innovation and technology to take products from an idea all the way to the end consumer. Facebook; Twitter; LinkedIn; . Speed to meet your needs on-demand. CNC / SCREW MACHINING. From simple to complex parts in low or high volume with Precision, Performance and . Rapid manufacturing of custom sheet metal parts .

Increasing demand for sheet metal fabrication from a wide range of major end users such as military & defense, aerospace, automotive, oil and gas, industrial machinery, medical devices . Are you interested in starting a metal business but not quite sure which area to focus on? Analysts forecast that the metal and metal manufactured products industry is growing at a CAGR of 5.2% and will reach .5 trillion in the next few years.. Therefore, starting your metal and steel business ideas in 2024 can be a noble idea.. The good news is there are several . As these industries continue to grow and innovate, the demand for sheet metal is expected to remain strong. Automotive Industry: The production of vehicles relies heavily on sheet metal for body panels, frames, and other components. The ongoing demand for cars, trucks, and other vehicles keeps the need for sheet metal high.Parallelly, the sheet metal fabrication segment, with a valuation of .2 billion in 2020, is anticipated to grow at a CAGR of 2.7% over the same period. This growth is fueled by the escalating demand for metal products across diverse .

As technology advances, so does demand for custom products. The metal industry is stepping away from mass production. Increasing on-demand fabrication is reshaping how metal parts are produced today. . The sheet .Sheet Metal Fabrication Services Market was valued at USD 10 billion in 2023 and is anticipated to register a CAGR of over 4.2% between 2024 and 2032. The construction and infrastructure sectors are major consumers of sheet metal products for applications such as roofing, structural components, and building facades.

India Sheet Metal Market Synopsis . India is the second-largest sheet metal consuming market in Asia Pacific. According to a recent report, the India Sheet Metal Market was estimated at USD 7.9 billion in 2019 and is projected to reach USD 9.5 billion by the year 2026, registering a Compouned Annual Growth Rate (CAGR) of 3.1%. Sheet Metal Fabrication. Sheet metal fabrication involves cutting, bending, and forming sheet metal into various shapes and components. This process is commonly used to create enclosures, chassis, and other structural components for a wide range of products. Key applications of sheet metal fabrication include:

Macro-economic factors significantly influence the market demand for sheet metal. Rapid industrialization, increased construction activities, especially in developing economies, drive the need for sheet metal products. The versatility of sheet metal also contributes to its high demand, finding applications in several industries, from automobile . At present, there is a big demand for metal business cards all across the globe. There are a wide variety of metal business cards that have gained popularity among customers. They can be of black metal, stainless steel, and gold. Furthermore, this metal-related business can be started with little money by people having a creative bend of mind.Q The annual demand for a product is 15,600 units. The weekly demand is 300 units with a standard deviation of 90 units. T. Answered over 90d ago. 100 % . SMI orders a relatively small number of different raw sheet metal products in very large quantities. The purchasing department is trying to establish an ordering policy that will minimize .

Companies in the sheet metal market are also focused on launching innovative products to meet the increasing demand for lighter and safer vehicles, incorporating advancements in steel production. High-strength steel sheets, introduced in the 980 MPa and 1180 MPa classes, offer significant strength improvements over conventional high-tensile .

sheet metal market outlook

Sheet Metal Market Outlook (2023 to 2033) Global demand for Sheet Metal Market is expected to reach a market valuation of US$ 316 Billion by the end of the year 2023, accelerating at a CAGR of 4% over the forecast period (2023 to 2033). The Sheet Metal Market is experiencing rapid growth, owing to the factors such as increasing demand for lightweight materials in the .This method meets consumers’ increasing demand for products tailored to their needs and preferences. It also allows manufacturers to quickly prototype and test new products, accelerating innovation in these dynamic industries. . Do you need a reliable sheet metal parts manufacturer? Shengen is the place to go. We specialize in sheet metal .On Demand Sheet Metal Fabrication, Sheet Metal Assembly and Custom Stamping. Where is sheet metal used? Sheet metal components are used in: • Industrial equipments and machinery • Aircrafts, automotive, railway vehicles, and excavators • Miscellaneous consumer products such as appliances and consumer electronics • Robotics • Military .

sheet metal market growth

TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise heat input and weld placement.

sheet metal products in demand|sheet metal market trends