sheet metal plane Flight testingBefore the Junkers J 1 could fly, IdFlieg, the Inspektorat der Fliegertruppen, the aviation administration arm of the German Army, required that . See more At work today we almost had a knock down drag out fight over knockout seals. What is the proper way to install a 1/2" knockout seal like this, from the inside of the box with the tabs to the outside or with the tab inside the box?:

0 · stainless steel model airplanes

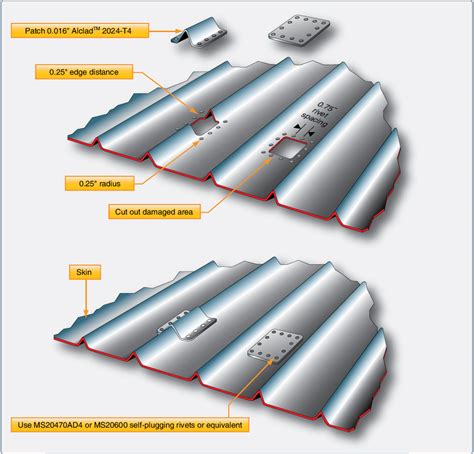

1 · splicing of skin sheets

2 · metal model military planes

3 · metal model airplane kits

4 · airplane sheet metal

5 · airframe sheet metal mechanic ad

6 · aircraft sheet metal construction

7 · aircraft sheet metal basics

Take the electrical wires that you will be connecting in the junction box and strip about 1/2 inch of insulation from the ends using wire strippers. This will expose the bare copper wire. Inside the junction box, you will see terminal screws or wire nuts.

stainless steel model airplanes

The Junkers J 1, nicknamed the Blechesel (Tin Donkey or Sheet Metal Donkey), was an experimental monoplane aircraft developed by Junkers. It was the first all-metal aircraft in the world. Manufactured early in the First World War, an era in which aircraft designers relied largely on fabric-covered wooden . See moreBackgroundAmongst the earlier pioneers and innovators in the field of aviation was the German engineer and aeronautical designer Hugo Junkers. During his early career he had . See more

how much does cnc machine operator make

Flight testingBefore the Junkers J 1 could fly, IdFlieg, the Inspektorat der Fliegertruppen, the aviation administration arm of the German Army, required that . See moreThe flight performance of the J 1 were evaluated during the test programme. Information was gathered from the pilots and the ground crew that serviced it. Apparently, the welded construction of the aircraft had problems on the ground that had been . See more• Grosz, Peter; Terry, Gerard (1984). "The Way to the World's First All-Metal Fighter". Air Enthusiast Twenty-Five: 60–63. ISSN 0143-5450 See more

The Junkers J 1 was an experimental mid-wing monoplane that incorporated various modern features, having a cantilever wing and an entirely metal . See moreData from Wagner and Nowarra (1971). German Combat Planes: A Comprehensive Survey and History of the Development of German Military Aircraft from 1914 to 1945.General characteristics• See more

• Junkers J 1 in Döberitz, 1915• The J 1 Projekt, homepage for a reproduction of the J 1 being built in Germany• The Hugo Junkers Homepage – Junkers J 1 info page See more There are five basic steps in the process of building an aluminum airplane. These steps are: (1) Planning, (2) Basic building, (3) Assembly, rigging and systems installation, (4) .His J-1 Blechesel (“Sheet Metal Donkey”) monoplane was the first successful all-metal airplane (1915), and his F-13 was the first all-metal transport plane (1919). Many Junkers aircraft had a corrugated sheet-metal skin, which was copied by .

Plane geometry deals with points, lines, polygons (A shape with more than two sides, i.e. square, triangle, hexagon, etc.) and circles on a flat surface (plane). Sheet metal flat patterns are done . All-Metal Construction Made Easy. Sheet metal aircraft construction is the most prevalent aircraft construction material by all measures, used extensively from jetliners to light, .Before getting into the detailed instructions for using Version 5 CATIA - Aerospace Sheet Metal Design, the following tutorial provides a step-by-step scenario demonstrating how to use key .Changing Sketch Plane After Sheet-Metal SOLVED. I've been building a part using a mixture of simple extruded bases and sheetmetal and have decided to change the relation of the plate to the its original sketch plane. The part is much more complex than the screenshot shows which is why I am not just redrawing this one part, I have just rolled .

sheet metal intake vs single plane. Jump to Latest 7K views 16 replies 8 participants last post by sumfoo1 Nov 18, 2014. gm383 Discussion starter. 427 posts Project sheet metal flange to plane A (hopefully) simple question: How does one project a 45 degree flange so that it ends at a certain distance from the origin plane? In the sheet metal program I have a part consisting of a flat horizontal face and a flange extruded at 45 degrees down. I need the flange to end at 12" from the X-Y origin plane. In this drawing, we have a piece of sheet metal that is bent, which includes a hole in one of the flanges. . as the other translations and rotations are locked down by Datum Plane A. Instead of attempting to get a datum axis from this feature, you only need to find a reliable way to get a centerpoint of the hole. Having a point that . The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

Sheet metal is a strong material, where the plasticity makes it easily workable. Steel is most often used to fabricate complementary parts for steel roof structures; however, sheet metal has many more applications. The sheet metal from Balex Metal is available in a wide selection of protective coatings and a rich gamut of colour options. Thus, in-plane shear testing is widely used to characterize sheet metals in order to obtain large strains of material without plastic instability. Moreover, in-plane shear testing is an important characterization tool for accurately evaluating the material response during in-plane shear deformation, which is common in the forming of sheet metal . At National Aviation Academy, one of the most important projects a student will learn deals with structures and sheet metal. Through classroom lectures and h.

Unearth a wide-ranging collection of general and kit plane aviation subjects, enriched with engaging imagery, in-depth technical manuals, and rare archives. . Interested in sheet metal construction? This is the place to be. This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others. . The decision to use sheet metal or plate metal isn’t merely about selecting different types of metal. It has far-reaching consequences for the entire project. The wrong choice can lead to structural failures, compromised functionality, or even safety hazards. On the other hand, selecting the right material ensures the project’s success in . Easy to customize plane parts – aerospace industry requires many customized parts and components. With aerospace sheet metal fabrication, you can produce virtually any part and component depending on the client’s requirements. . With precise sheet metal fabrication capabilities, KDMFAB is a trusted aircraft OEM parts supplier in the .Check out our sheet metal plane selection for the very best in unique or custom, handmade pieces from our tools shops.

Shop for Galvanized Steel Sheet, Plate and Floor Plate at America's Metal Superstore. Largest selection of Galvanized at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! - - - - Select Size; 1 x 2 Ft. 1 x 4 Ft. 2 x 2 Ft. 2 x 4 Ft. 3 x 4 Ft. 4 x 4 Ft. . In the screencast below, I added a parallel constraint between projected sketch and sketch for creating sheet metal. Since the projected sketch is linked to the component, it stays parallel when you go back in timeline and rotate the body.The aluminum sheet thickness of C919 aircraft plane is up to 200mm, and it must also meet the performance requirements of corrosion resistance, high strength, fatigue resistance, dimensional stability, easy machining (polishing, cutting, etc.) . The typical production process of aerospace aluminum sheet metal is: raw material - casting .Sheet metal aircraft construction is the most prevalent aircraft construction material by all measures, used extensively from jetliners to light, single engine airplanes and kits over the past five decades. Furthermore, virtually all other aircraft types use sheet-metal construction to some degree – whether an instrument panel on a composite .

Hey guys, I've been wondering if there's any way that i can select mulitple flanges and have them different heights? So they still miter and crash less? In solidworks, you can select two flanges, one being 1" and the other . Determining Stress-Strain Curves of Sheet Metal in the Plane Torsion Test A. E. Tekkaya, K. Pohlandt, lnstitut fur Umformtechnik, Universitat Stuttgart/Germany - Submitted by K. Lange (1) The plane torsion test has been studied for determining the flow curve kf(7) of sheet metal. This test was first proposed by Marciniak and Kolodziejski far a .

Our fabricated sheet metal valley pans work great with our aluminum Stealth heads, Edelbrock RPM heads, or any other aftermarket heads which feature an unbroken deck surface where the lower edge of the head's deck surface meets the edge of the valley pan. They will also work with factory cylinder heads, however there may be a small gap where the lower deck surface has a .From high quality metal sheets to amazing 3D models, no glue nor solder required. . 5B monoplane was purchased in 1932 by the famous aviator, Amelia Earhart, who called it her “Little Red Bus”. The plane was powered by a 450 hp engine with a cruise speed of 155 mph. Flying this plane in 1932, Amelia became the first woman to fly nonstop .

This video takes you through the process of using the lofted, contour, flange and tab commands to create a transition piece (round to flat) in Solid Edge She.What is Electric Field Due to a Uniformly Charged Infinite Plane Sheet? Let us consider an infinitely thin plane sheet that is uniformly charged with a positive charge. Let 𝜎 be the charge density on both sides of the sheet. At point P the electric field is required which is at a distance a from the sheet. Through point P, a Gaussian . Hi , Thank you for your response! One way that may work is to use Parallel constraint in the sketch mode. In the screencast below, I added a parallel constraint between projected sketch and sketch for creating sheet metal. Since the projected sketch is linked to the component, it stays parallel wh.Limiting principal strains were measured by two different techniques of biaxial stretching of sheets, one of which permits free deformation in a flat plane, while the other causes constrained deformation in contact with a rigid or rubber punch. The latter method, which relates well with industrial experience, produces larger limiting strains under identical degrees of biaxiality. A .

splicing of skin sheets

Elastic–plastic behavior of two types of steel sheets for press-forming (an aluminum-killed mild steel and a dual-phase high strength steel of 590 MPa ultimate tensile strength) under in-plane cyclic tension–compression at large strain (up to 25% strain for mild steel and 13% for high strength steel) have been investigated.From the experiments, it was found that the cyclic .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Bends that are in the same plane need to be designed in the same direction to avoid part re orientation, to save both money and time. Keeping the bend radius consistent will also make parts more cost-effective. Thick parts .Mirroring the Sheet Metal Bends. When you mirror a sheet metal part, many of the bends are mirrored as well. Creating an Edge Flange. Create an edge flange using the edit sketch profile and offset options. Mirroring a Sheet Metal Feature. You can mirror sheet metal bodies as well as selected sheet metal features. Use the Right Plane to mirror .

metal model military planes

how much do sheet metal workers make in canada

metal model airplane kits

I use Coroplast and hold it to the top and bottom with clothes pins or large binder clips, then staple targets directly to the Coroplast. I used OSB a while but it kept disintegrating. Another good source for targets and backers is letargets.com They have everything from military silhouette to bullseye and zombie targets.

sheet metal plane|aircraft sheet metal basics