sheet metal processes time estimate Similar to other CNC machining cost, the costs involved encompass labor and machinery depreciation. Most manufacturers employ a simplified cost calculation method, which factors in the unit time cost . Many homeowners pair their light-color metal roofs with soft blues, greens, or white exteriors. Light Stone, Almond, and white are the go-to choices when wanting a lighter metal roof color. There are also less subtle color combinations that can achieve a .

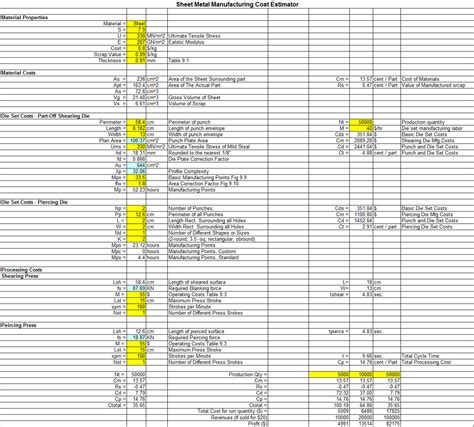

0 · sheet metal production cost calculator

1 · sheet metal production cost

2 · sheet metal parts cost estimator

3 · sheet metal manufacturing cost formula

4 · sheet metal manufacturing cost estimator

5 · sheet metal fabrication estimate

6 · sheet metal design cost calculator

7 · sheet metal cost calculator

Darker colored cabinets will make them pop while white or pale neutral cabinets will allow them to seamlessly blend into your kitchen. White appliances also pair well with wooden cabinets, giving a warmer look and feel .

The ability to accurately estimate the cost and time required for sheet metal fabrication projects is essential for maintaining profitability and meeting project deadlines.Express Estimator is a cloud-based sheet metal manufacturing estimating and quotation software, available for a low subscription.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Similar to other CNC machining cost, the costs involved encompass labor and machinery depreciation. Most manufacturers employ a simplified cost calculation method, which factors in the unit time cost .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on .Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and .

Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .Calculation of Sheet Metal Quote. Sheet metal fabrication prices are based on job time: Laser cutting is /minute, and each small hole is calculated at . CNC Pricing: /minute. CNC .When you need estimates for sheet metal costs for construction projects in DC, MD, or VA, call ADJ Sheet Metal. 15+ years’ experience, great reviews. Call Us Today (301) 283-3000 Call Us Today (301) 283-3000Sheet metal fabrication is one of the most popular manufacturing processes for prototyping and volume manufacturing of metal products.In today’s highly competitive market, understanding the cost structure of a product is critical to improving the process and the right pricing strategy.

67 Sheet Metal Process Planner jobs available on Indeed.com. Apply to Planner, Production Scheduler, Sheet Metal Mechanic and more! . and labor to accurately estimate the cost of producing sheet metal parts and assemblies. . Full-time. Pay: .00 - .00 per hour. Benefits: 401(k) Dental insurance; Health insurance;

sheet metal production cost calculator

Sheet thickness (in): Die edge radius (in): Punch edge radius (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety:Cost estimating sheet metal manufacturing and fabricated parts and products generally consists of a few basic manufacturing processes namely, cutting a blank to size, brake forming, welding, grinding, deburring and finishing (whether it be chemical coating or painting.). This sheet presents a method for the feature oriented quotation costing of sheet metal parts based on a specifically .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight Discover how to estimate and manage the sheet metal fabrication cost. Learn about key cost factors, main fabrication processes, and cost-saving strategies. . By incorporating DFM principles, designers can reduce the complexity of the fabrication process, thereby lowering production time and costs. Key aspects of DFM include: Simplifying Designs;

Sheet metal working machines have revolutionized the manufacturing industry, transforming processes and unlocking new possibilities. These machines enable manufacturers to shape, cut, and bend sheet metal into intricate components with precision and efficiency. Their impact extends across various sectors, including automotive, aerospace, electronics, and .

Sheet Metal Forming Processes. Sheet Metal Forming Processes. Introduction. Ratio – Surface Area:Volume is very high for sheet metal process. Plates – thickness > 0.25 inches Boilers, bridges, ships, etc. use relatively thick plates Usually sheet forming is done on relatively thin material. Shapes can be of various size. 649 views • 11 .

Blank design and strain estimates for sheet metal forming processes by a finite element inverse approach with initial guess of linear deformation C.H. Lee, H. Huh * . low computing time, affording the determination of the strain distribution in a .

sheet metal production cost

sheet metal parts cost estimator

sheet metal manufacturing cost formula

The study by Ingarao et al. (2011) can be considered one of the milestones of sustainability in metal forming processes. Despite emphasizing energy efficiency and the use of resources for sheet .How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle. . For example, with a cycle time of 12 seconds, efficiency 80,5% and a Machine hourly cost of 77,3 Euro we obtain: . As deep connoisseur in sheet metal working processes, Dallan focused its development in .

Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. Find the right fit for your metalworking business.

Sheet metal forming process Chapter 7 Introduction Sheet metal forming operations produce a wide range of consumer and industrial products, such as metal desks, appliances, aircraft fuselages, car bodies, and kitchen utensils. Sheet-metal forming also called press working, press forming or stamping, is among the most important of metalworking processes, dating back to .

5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are . The manufacturing of a sheet metal product requires several phases to be completed in a precise sequence. These phases may include cutting, forming, welding, foaming, painting, assembly and packaging.Here's a brief article about just that concern, with just generalities about cost vs. tolerance in sheet metal fabrication. Scroll to the end to see the conclusion on reasonable tolerances. Realistically, tighter tolerances are going to force fabrication to more expensive processes in terms of capital equipment, tooling, and/or skilled labor costs.

The boundary in metal forming process at time t can be assumed to be divided into three parts, namely S1 on which velocity is prescribed, S2, which is free and S3 where frictional contact occurs. The following conditions apply on each type of boundary. (6) On S1: (v-vo) Perform sheet metal inspections with our award winning Planar 2D Inspection Machine, the fastest and most automated 2D inspection system in the world. . insert or fold at the end of a just-in-time assembly process can destroy delivery dates. . To help accommodate this limitation many 3D inspection software packages will try and estimate the .MIT 2.810 Manufacturing Processes and Systems Homework 4 Solutions Sheet Metal Forming October 7, 2015 Problem 1. Springback . Time estimate per part: Using the cycle time from Boothroyd (equation 9.22), t = 3.8 + 0.11(L+W) seconds for

Sheet Metal Forming Processes. Let’s talk a little more about sheet metal forming’s various processes as each one is better-suited for making different items. Laser Cutting. Before metal sheets get formed, many times the initial flat patterns are laser cut first. Laser cutting uses a high-powered laser to cut shapes into flat metal sheets.

Sheet metal production lines nowadays are more and more automated, with increasing number of processing modules. Knowing how to balance a production system has become a strategic skill for the production manager in order to optimize the line and increase the productivity. Production systems consist of a series of machines, each one performing one part of the process. With their sheet metal cost estimation software, estimators can bid farewell to the days of manual data entry and scattered information. Here’s how their software can revolutionize your cost estimation process: Unfolding Sheet Metal Components and Vectorizing PDFs Paperless Parts’ software allows you to quickly unfold sheet metal components .

playsted sheet metal

Sheet metal forming process Chapter 7 - Download as a PDF or view online for free . • Most high-pressure pumps at this time, though, operated around 500–800 psi (3–6 MPa), some reaching 1600 psi (11 MPa). . L = length of sheet in direction perpendicular to stretching t = instantaneous stock thickness Yf = flow stress of work metal .

Press brake bending is a commonly used process for sheet metal part fabrication. It has been observed that the final bend angle, which is the angle achieved upon removal of the punch, is smaller .This is because turret punch machines only display the total machine run time per entire sheet blank , whereas the punching process depends not only on the parts themselves but also on the punching tools used and punching routes . Machine Learning, Turret Punch Machine, Time Estimate, Sheet Metal Fabrication Cost, Automation, Industry 4.0 . 1 . Deep Drawing Process for Sheet Metal. satyendra; August 28, 2023; 7 Comments ; Anisotropy, Blank, Blank holder, Deep drawing, die, drawability, Earing, Expanding, Ironing, Limiting draw ratio, lubrication, Necking, Plastic strain ratio, Punch, Strain hardening exponent, Tearing, Trimming, Wrinkling,; Deep Drawing Process for Sheet Metal. Deep drawing is a .

plastic wire holder in metal box

$14.99

sheet metal processes time estimate|sheet metal cost calculator