beading process in sheet metal Sheet metal processes can be broken down into two major classifications and one minor classification. Shearing processes: processes which apply shearing forces to cut, fracture, or separate the material. Forming processes: processes . Discover sandals, flats, boots, heels, wedges and our highly-coveted jeweled flip-flops. Designed with ultimate comfort and playful design, shop Yellow Box and find your favorite footwear for any occasion.

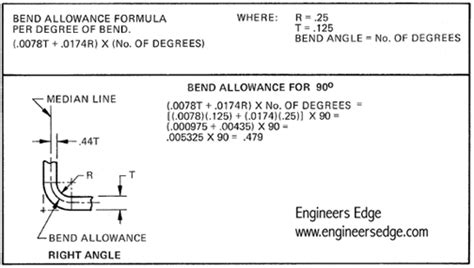

0 · sheet metal calculation formula pdf

1 · sheet metal bending process pdf

2 · sheet metal bending design guide

3 · draw beads in metal forming

4 · bending process pdf

5 · bending operation in sheet metal

6 · bending drawing sheet metal

7 · beading machine for sheet metal

Yankee Sheet Metal offers architectural flashing, sheet metal punching, welding, stainless steel kitchen countertops, copper work, metal bending, and more. We have experience with many processes and techniques in manufacturing, fabrication, and CNC Plasma Cutting Services.

These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be.Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain .

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies . Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The .

Sheet metal processes can be broken down into two major classifications and one minor classification. Shearing processes: processes which apply shearing forces to cut, fracture, or separate the material. Forming processes: processes . When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s . Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or .Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part’s edge. This bead can be formed over a straight or curved axis.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead.

These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be.

Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. In some cases bending may produce a small change in sheet thickness.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE " Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process. Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.

Sheet metal processes can be broken down into two major classifications and one minor classification. Shearing processes: processes which apply shearing forces to cut, fracture, or separate the material. Forming processes: processes which cause the metal to undergo desired shape changes without failure, excessive thinning, or cracking. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?” Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape.Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part’s edge. This bead can be formed over a straight or curved axis.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be.Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. In some cases bending may produce a small change in sheet thickness.

We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE " Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process. Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.

Sheet metal processes can be broken down into two major classifications and one minor classification. Shearing processes: processes which apply shearing forces to cut, fracture, or separate the material. Forming processes: processes which cause the metal to undergo desired shape changes without failure, excessive thinning, or cracking. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?”

sheet metal calculation formula pdf

sheet metal bending process pdf

Here we explore six methods to add structure to sheet metal, helping ensure your project posseses both strength and functionality. Bending is just what it sounds like – creasing a sheet of metal to achieve a curved or angular shape.

Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part’s edge. This bead can be formed over a straight or curved axis.

sheet metal bending design guide

draw beads in metal forming

bending process pdf

You see, a driver who enters into a yellow box and stops in it is in reality committing an offence. Who says so? Well, the Road Transport Ordinance 1978 Section 119 (2). And it also carries a RM300 fine as well. In driving, there is actually no necessity to .

beading process in sheet metal|sheet metal calculation formula pdf