trimming process in sheet metal In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the . Did you know that one of the most common questions I get asked is “What should I use to glue my metal filigrees?” There is alot of “sticky stuff” out there to use, but my top two picks for metal are: Glossy Accents; E6000

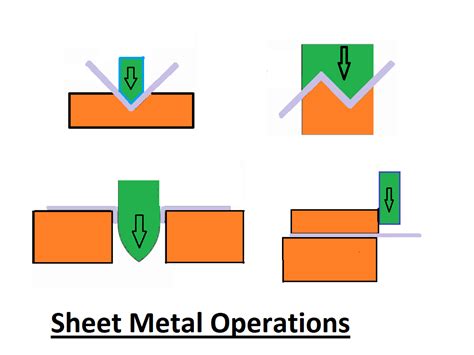

0 · sheet metal operations with diagrams

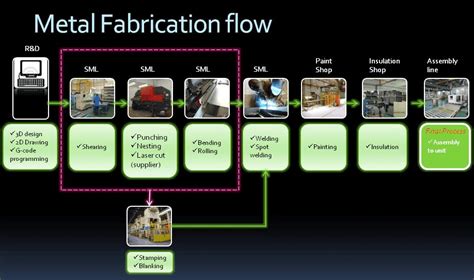

1 · sheet metal manufacturing process types

2 · sheet metal manufacturing process pdf

3 · perforating operation in sheet metal

4 · notching operation in sheet metal

5 · how to fabricate sheet metal

6 · cutting clearance for sheet metal

7 · blanking operation in sheet metal

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and .

Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It involves removing excess material from a workpiece, bringing it to its desired size and shape.

In the realm of sheet metal manufacturing, trimming is a shearing process that .Trimming is the process of cutting away any unwanted or excess material from the .

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed part. It is a crucial step that helps to achieve the desired size, shape, and finish, ensuring the .

Trimming is the process of cutting away any unwanted or excess material from the sheet metal part. This process not only results in a smoother edge finish, enhancing the part’s appeal and safety, but it also ensures that .Any mechanical cutting operation such as blanking, piercing, shearing, slitting, or trimming reduces edge ductility. Each of these processes generate a zone of high work hardening and a .Trimming is the removal of excess metal from a stamped part to allow the part to reach the finished stage or to prepare it for subsequent operations. This article presents an analysis of .

Sheet metal cutting, a fundamental process in the metalworking industry, involves the precise removal of material from sheet metal stock to form a specific part or component. This process, essential in shaping the metal sheet .Learn about different types of sheet metal cutting processes, such as shearing, blanking, punching, slotting, lancing, nibbling, perforation, piercing, notching, and trimming. Trimming is the last operation after deep-drawing to remove excess . The sheet metal cutting process involves placing the sheet between these two blades, which are then forced together to cut the metal. With most shearing machines or implements, the lower blade is stationary while the .

Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to caused the material to fail. The most common cutting processes are performed by applying a shearing force, and are . The sheet metal trimming process, an integral part of the sheet metal manufacturing cycle, requires a comprehensive understanding to troubleshoot common defects. Trimming in the context of sheet metal . The importance of trimming cannot be overstated, as it plays a critical role in achieving the desired quality and safety of sheet metal parts. The Trimming Process. The trimming process begins with placing the sheet metal .Sheet metal routing Creator of the “bridge-cut” process, CRENO aluminum stack routers automate the sheet trimming process with a very high level of productivity and quality. This solution offers: Complete supervision of the process for each .

For the shearing process in sheet metal, sheets are fabricated into multiple components – all of which can now be used to manufacture different items. . Now that we understand the sheet metal forming, shearing, and cutting process, let’s also look into the different types of shearing processes that are usually employed by most manufacturers:Notching is a sheet metal cutting process that involves the removal of material from a work piece, starting at the edge and cutting inward. The objective of notching is to create a sheet metal part with a desired profile. Notching is often performed as a progressive process, each operation removing another piece to make the correct contour. .

sheet metal operations with diagrams

Pinch trimming is a rather unconventional metal cutting process, because it does not employ some of the basic guidelines associated with conventional cutting. Think of pinch trimming as a metal squeezing process in which the metal is pinched on a vertical wall to the point at which it is separated from the scrap. Unlike conventional cutting .After meticulous material selection, the next stage in sheet metal fabrication is cutting the metal into the desired shape and size as per the design specifications. This step is vital for setting the foundation of the final product. Here are three key steps in the metal cutting process: During the stamping process and cutting phase, the metal sheet is placed in a press, where a punch forces it through a die. This action shears the metal deformation along the die’s edges to produce the desired part. The blanking process typically yields clean, smooth edges, although there may be instances of rough edges or burrs that need .The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its core, driving the production of high-quality components. Precision, efficiency, and innovation are at its core, driving the production of high-quality components.

gioia steel accent cabinet

Shaving/Trimming is a finishing operation in which shearing off of burrs from the cut edges is carried out in order to make the edges smooth and also impart .Slitting is a sheet metal cutting process with circular knives, which is used to split wide coiled sheet metal into narrower widths or for edge trimming of rolled sheet. The slitting process is schematically shown in Figure 1.6. The slitter knives are mounted on two arbors together with spacers . The spacers determine the width of the cut and .

The key types of cutting operations are shearing, blanking, punching, and trimming. Engineering analysis of sheet metal cutting considers process parameters like clearance between the punch and die, stock thickness, material properties, and cut length. The cutting force is estimated based on the material shear strength, thickness, and cut length.

girl friends metallic fabric

sheet metal manufacturing process types

In general, each piece of sheet metal is put between two different parts of the cutting process. The upper part is known as a punch, while the lower part is known as a die. Technically, each of these components can be referred to as a die, but to distinguish one from the other, the upper part is given a separate name. Types of Metal Trimming Process Manufacturing Technologies. There are four primary types of metal trimming available including: . In the early days of this technology, lasers were limited to only trimming thin sheet metal. Since more powerful resonators have been developed, lasers are now capable of cutting steel up to 1.5 inches thick. It is .This process of converting sheet metal to the desired shape consists of two operations: cutting to the required geometry and forming the desired shape. The former operation leads to rupture of the sheet, whereas in the case of the latter, the purpose is to plastically form the sheet. The research deals with the process of sheet metal cutting

In the process of making metal furniture, the sheet metal notching process is used to create finer and perfect edges. Manufacturing of gym equipment; Gym equipment needs to be safe to use. Proper fabrication .

The sheet metal cutting process is an important part of fabrication or metalworking, beginning with choosing the appropriate material and defining the desired shape and size. To remove superfluous material from a metal . Prediction of the trimming process using finite element (FE) simulation is often required to increase the efficiency of the process. Moreover, the virtual trimming of sheet metal parts is important as it provides information on the stress triaxiality state and strain contours which is difficult to obtain directly from experiments. It works exceptionally well for sheet metal and thin materials. Water Jet Cutting: Advantages and Applications. Water jets mix water with abrasive particles to cut metal. This cold-cutting process prevents heat distortion. It cuts thick materials while maintaining material properties. Plasma Cutting: A Popular Method for Metal Fabrication .

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

The sheet metal cutting process is a particularly important part of fabricating sheets of metal into components of a wide array of consumer and industrial products. Used to remove unneeded material, shearing involves the use of machines or tools to precisely cut sheet metal. Cutting processes like shearing neither require heat nor produce waste . What is trimming in manufacturing process? The trimming process is the shearing of excess material from the headed configuration of complex shapes so as to obtain the final design and specifications. What are the four types of sheet metal working? Different Types of Sheet Metal Operations are: Punching Operation. Piercing Operation.

Shearing Process Shearing is the process of cutting sheet metal strip. The shearing action takes place in a sheet metal. Cutting processes are those in which a piece of sheet metal is separated by applying a great enough force to caused the material to fail. The most common cutting processes are performed by applying a shearing force, and are . We manufacture the Sheet Metal Curling Tool to cut, trim, and curl the edges of round parts. The Sheet Metal Curling Tool are used in metalworking industries. . Curling is a valuable process in sheet metal fabrication, enabling the creation of diverse shapes and features for various applications. By following safety guidelines and using . Sheet metal cutting is a fundamental process in manufacturing that involves various techniques such as laser, plasma, and waterjet cutting. This article provides a comprehensive guide to these methods, exploring the principles behind each and their applications. From understanding the equipment used to the intricacies of different cutting . Edge curling is a sheet metal forming process that involves rolling the edge of a sheet metal part into a curl or flange. This process has several benefits, including: . Sheet Metal Fabrication: Trimming beading machines are used to trim and bead sheet metal components for a range of applications, .

sheet metal manufacturing process pdf

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting.

However, there are more aspects to the septic system, and one necessary part is the distribution box, sometimes referred to as the d-box. A septic system is more than just a septic tank. The septic system works by sending wastewater out of your home through pipes that take it .

trimming process in sheet metal|blanking operation in sheet metal