cnc copper manufacturers At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our . The incentive for me is that they will stick a Siemens controller on it. I know a couple folks who have them (YCM with Siemens), who seem to like it. I like the BBT spindle too - IIRC you can get a 15k or 20k DD on a 40 taper, and they have a really nice torque curve.

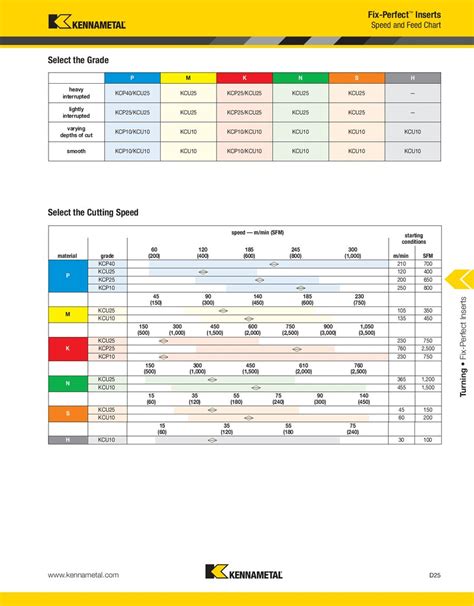

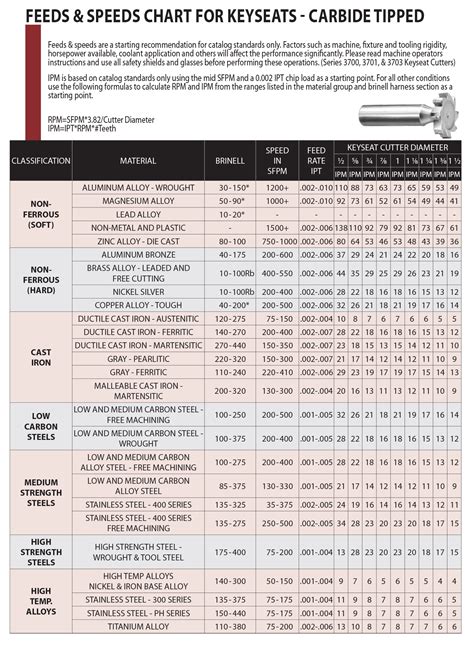

0 · turning copper speeds and feeds

1 · speeds and feeds for copper

2 · machinability of copper 110

3 · end mills for copper

4 · cutting speed for copper milling

5 · copper segregation procedure machine shop

6 · copper segregation policy machine shop

7 · copper machinability chart

This allows each Yasda machine to utilize the highest damping capacity to absorb .

turning copper speeds and feeds

Copper is an incredibly versatile metal, making it an optimal choice for producing CNC machined custom parts. The alloy has several useful properties alongside its versatility—this is why companies working in industries such as electrical, construction, . See moreWe offer a complete copper CNC machining service and can produce complex copper parts inC110 andC101. Copper parts are . See moreProtolabs Network offers a state-of-the-art copper CNC machining service, guaranteeing consistent quality and fast turnaround times. We have over 1,600 milling and turning machines at our disposal, which means capacity is virtually always available and . See moreNeed precision copper components? Monti offers expert fabrication, from simple bus bars to complex assemblies. Get a free quote today!

At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our .We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.Need precision copper components? Monti offers expert fabrication, from simple bus bars to complex assemblies. Get a free quote today!

At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our proprietary software helps to reduce production time and minimize scrap.Why Choose Our Copper Cnc Machining Service? Certifications & Quality Machining; Top Copper Cnc Machining Case Studies; The Material Type Of CNC Machining Copper AlloyDepending on requirements, PTS manufactures customized copper components in turning and milling or in cold forming tumbling presses. With the latest CNC machines, we manufacture precision copper components to exact and tight tolerance standards. As an alternative to CNC production, cold rolling is available as a cold forming process.XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.

Our RD-series CNC tube bending machines will save you money by providing maximum flexibility while offering the latest in features and advanced technology. Winton’s CNC benders can be used as stand along machines or building blocks to create a fully automated fabrication cell.With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you improve the design and reduce the cost, you can upload your CAD files to get a free online quote.Winton Machine is a leading manufacturer of tube and coax fabrication equipment. From bending to end forming, we offer versatile solutions for diverse industries.

Copper CNC machining technology ensures perfect repeatability, from the first part to the last, in any quantity, whether you need a single prototype component or high volume production runs with tens of thousands of pieces.We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.

Need precision copper components? Monti offers expert fabrication, from simple bus bars to complex assemblies. Get a free quote today!

At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our proprietary software helps to reduce production time and minimize scrap.

Why Choose Our Copper Cnc Machining Service? Certifications & Quality Machining; Top Copper Cnc Machining Case Studies; The Material Type Of CNC Machining Copper Alloy

Depending on requirements, PTS manufactures customized copper components in turning and milling or in cold forming tumbling presses. With the latest CNC machines, we manufacture precision copper components to exact and tight tolerance standards. As an alternative to CNC production, cold rolling is available as a cold forming process.XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.Our RD-series CNC tube bending machines will save you money by providing maximum flexibility while offering the latest in features and advanced technology. Winton’s CNC benders can be used as stand along machines or building blocks to create a fully automated fabrication cell.With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you improve the design and reduce the cost, you can upload your CAD files to get a free online quote.

Winton Machine is a leading manufacturer of tube and coax fabrication equipment. From bending to end forming, we offer versatile solutions for diverse industries.

speeds and feeds for copper

snap on tool box metal thickness

XYZ Sheet Metal is commercial contractor working in the greater Boston area.

cnc copper manufacturers|cutting speed for copper milling