basics of cnc machining What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3. america west sheet metal inc. 7233 atoll avenue. north hollywood, ca 91605. tel: .

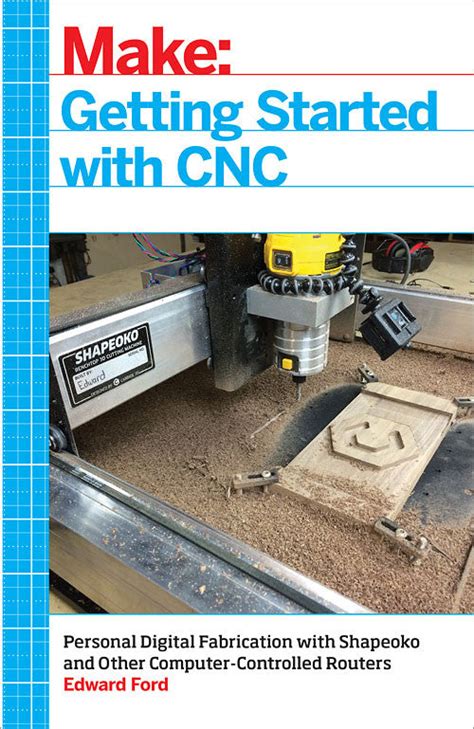

0 · make getting started with cnc

1 · getting started with cnc machines

2 · cnc what you need toknow

3 · cnc machining for dummies

4 · cnc machining basics pdf

5 · basics of cnc pdf

6 · basic knowledge of cnc machine

7 · basic cnc for beginners

The welding of sheet metal requires the use of a wire or a tig welder. This is probably the most efficient way to weld auto body panels. However, if you .

make getting started with cnc

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer .

A: In order to use a cnc machine efficiently, it is important to have a proper understanding of the basic principles of CNC machining, which include thermally controlling .

Due to automation, CNC machining is a common manufacturing process known for its precision, accuracy, and capability for complex product design. This article will discuss CNC machining basics, its process, . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3. If you are a beginner, if you are looking at a CNC machine as a new hobby, if you are starting your new business or, if you are adding CNC technology to your business, this guide will be a good place to start. CNC machining is a process in which computer-controlled tools remove material from a workpiece to create the desired shape or finish. CNC machining is often used for creating prototypes or small batches of parts, as it .At the most basic level, CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process that uses computer software to dictate the movements of machine tools to shape parts from raw materials. – .

getting started with cnc machines

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. Here’s the thing–learn the CNC Basics first before you try to acquire a machine. Understanding these CNC basics will help you understand your potential new machine’s specs and documentation. They’ll help you understand what people on forums (great learning resources!) are talking about. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is until the material forms the input designed part. How CNC Machining Works?

A: In order to use a cnc machine efficiently, it is important to have a proper understanding of the basic principles of CNC machining, which include thermally controlling the pieces, programming the controller, stirring, selecting the correct tools appropriate for the pieces, and setting the parameters for the materials and the operations. Due to automation, CNC machining is a common manufacturing process known for its precision, accuracy, and capability for complex product design. This article will discuss CNC machining basics, its process, application, and benefits. CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3.

If you are a beginner, if you are looking at a CNC machine as a new hobby, if you are starting your new business or, if you are adding CNC technology to your business, this guide will be a good place to start. CNC machining is a process in which computer-controlled tools remove material from a workpiece to create the desired shape or finish. CNC machining is often used for creating prototypes or small batches of parts, as it is more precise and faster than traditional methods such as manual machining or casting.At the most basic level, CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process that uses computer software to dictate the movements of machine tools to shape parts from raw materials. – Precision: Extremely accurate in creating detailed parts. – Efficiency: Speeds up manufacturing significantly.

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. Here’s the thing–learn the CNC Basics first before you try to acquire a machine. Understanding these CNC basics will help you understand your potential new machine’s specs and documentation. They’ll help you understand what people on forums (great learning resources!) are talking about.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is until the material forms the input designed part. How CNC Machining Works? A: In order to use a cnc machine efficiently, it is important to have a proper understanding of the basic principles of CNC machining, which include thermally controlling the pieces, programming the controller, stirring, selecting the correct tools appropriate for the pieces, and setting the parameters for the materials and the operations.

Due to automation, CNC machining is a common manufacturing process known for its precision, accuracy, and capability for complex product design. This article will discuss CNC machining basics, its process, application, and benefits.

cnc what you need toknow

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1. What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3. If you are a beginner, if you are looking at a CNC machine as a new hobby, if you are starting your new business or, if you are adding CNC technology to your business, this guide will be a good place to start. CNC machining is a process in which computer-controlled tools remove material from a workpiece to create the desired shape or finish. CNC machining is often used for creating prototypes or small batches of parts, as it is more precise and faster than traditional methods such as manual machining or casting.

cnc machining for dummies

major components of cnc machine

Experience: Wenger Roofing & Sheet Metal

basics of cnc machining|cnc what you need toknow