etching sheet metal This is how I etch designs into metal. I show you not only two different chemical options, but also an alternative transfer paper to Press-N-Peel Blue specia.

This listing is for a Western Electric WE KS-14703 755A Speaker in Original WE Cabinet with WE speaker Transformer. The speaker is in good working condition and sounds quite nice. The measured DCR is 2.3 ohms. The cosmetics of .

0 · types of metal etching

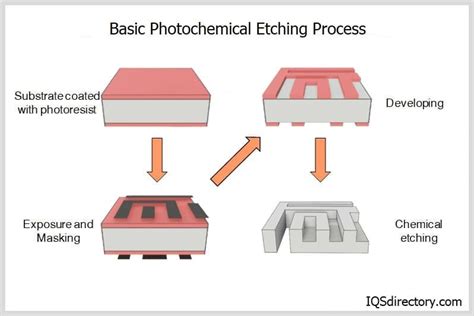

1 · photochemical etching

2 · metal etching techniques

3 · how to etch stainless steel

4 · how do you etch metal

5 · etching solution for metal

6 · best acid for etching steel

7 · acid etching on stainless steel

Is Welding Without Gas Possible? Fortunately, there is a solution to this issue, and it involves gasless MIG welding. We’ll examine how to weld without gas in further detail in the piece that follows, as well as some of the various things you should keep in mind.

How to create your design. Etching the metal step-by-step. How to finish and polish your etched metal. Safety tips for metal etching. Troubleshooting common problems. Ever had the urge to etch your own designs onto metal? .Metal etching is a subtractive manufacturing technique used to etch complex patterns, drawings, or marks on metal surfaces. It is also known as acid etching or chemical etching. In order to accomplish the required design, this technique . Elcon Precision specializes in advanced chemical etching processes to create complex and highly accurate components from almost . This is a simple way to accomplish fine, precise designs without needing a CNC or laser cutter. I use ferric chloride and Press-N-Peel blue, but I also show a DIY etchant mix and alternative to.

Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from almost any . This is how I etch designs into metal. I show you not only two different chemical options, but also an alternative transfer paper to Press-N-Peel Blue specia.Curio 5 in x 7 in metal etching sheets ; These anodized metal sheets are perfect for etching because the colored surface contrasts with the silvery aluminum underneath ; 1 sheet each of 5 in. x 7 in. black, gold, and pink metal etching .Sheet Thicknesses. We can etch thicknesses generally between .002"-.060'' depending on the part's requirements. Flat Parts. We only etch 2-dimensional parts in metal sheets. Forming is a secondary operation that we offer. Etching .

In this guide, we delve into the techniques and tips that elevate Metal Etching from a mere process to a true form of artistic expression. Whether you’re a seasoned metal artist or a curious beginner, this journey will guide you through the nuances of successful metal etching, uncovering the secrets behind achieving detailed designs, mastering various etching methods, and . Sheet Metal Fabrication provides custom EMI shielding manufacturing solutions, and is performed using various methods, including CNC punching, laser cutting, and stamping and the chemical etching process. CNC Punching: This process involves using a computer-controlled machine to punch holes or cut shapes into sheet metal. CNC punching can .Multi-chapter guide to Metal Etching describing: what metal etching is, how metal etching works, types of metal etching tools, metal etching uses, metals used. . In both cases, the image is transferred onto the metal sheet. When the image is carved into the maskant, it results in a recessed pattern. Conversely, when the maskant agent is used . Sheet metal notching: Tube notching: Process mechanism: A punch press is used in removing unwanted materials on the sheet edges. In tube notching, different angle cutting are made on the metal tube. Speed: A sheet metal notching is fast hence an advantage to the cycle time. . Why Laser Etching? The power of laser etching has been grossly .

types of metal etching

The material is then chosen and, following cleaning, laminating, printing, and development, the metal sheet is exposed to chemicals that dissolve all unprotected surfaces, yielding production-ready parts. When it comes to manufacturing custom metal parts that are thin, these are some of the advantages of utilizing chemical etching for production:

Metal Etching Sheet Bending Photo Etched Parts Assembly Bender Modeling Tools . Visit the Fancyes Store. 4.8 4.8 out of 5 stars 8 ratings | Search this page . .29 $ 28. 29. Coupon: Apply 5% coupon Shop items | TermsOur quality-assured nickel etching service is compatible with all nickel grades, ensuring the rapid production of burr and stress-free components.Our nickel etching process uses a controlled chemical reaction, selectively dissolving material from a metal sheet. For more information about etching service, please email today on [email protected].

Etching metal is a technique that engraves complex textures on the surface of materials by chemical reactions or physical collisions. Its processes provide a canvas of possibility for expression on panel surfaces. Therefore, the etched stainless steel sheet has a high aesthetic and complex pattern.The popularity of Tungsten makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts .We can etch metal with a thickness range from .001" to .060". (results may vary based on sheet size, metal thickness, and production volumes) Tolerances. Dimensional tolerances are +/- 15% of metal thickness and a minimum of approximately +/-.001" with thicknesses of .005" and under. .Comprehensive range of metals. Metal etching can be applied to virtually any metal, regardless of its hardness or temper. Annually, we process over 100 tonnes of sheet metal, covering more than 2,000 metal types – surpassing any other chemical etching supplier.

photochemical etching

Importance of Laser Etching in Sheet Metal Fabrication. The process of laser etching involves utilizing a focused beam of laser to make an impression on a material’s surface, resulting in a specific design or marking. .

The chemical etching process starts with the selection of the required sheet metal, with suitable thicknesses ranging from 0.010 mm to 2.5 mm and sheet sizes up to 600 mm by 1500 mm. . is sprayed onto the developed sheet. The .Safari Metal trading company is one of the famous and trusted leading importer and exporter of stainless steel in the form of Pipe, Tube, Sheet, Plate, . S.S Etching Sheet Titanium Gold / Bronze / Rose Gold / Blue / Black •Hairline .

sheet metal fabrication consultation christchurch

Use your Curio to create beautiful designs on metal surfaces using the Stippling & Etching tool. Shop all Curio products: https://www.silhouetteamerica.com/s.Etching holes in sheet metal rather than cutting Hello, for a project I'm planning im doing cost assessment to see if I'm going to make a finished "product" or just make a prototype. Am I going to program and implement it on a bread board, or am I going to actually make an enclosure for it.

The chemical etching technical data below highlights our chemical etching capabilities and lowest tolerances achievable based on many variables such as metal thickness, metal type, sheet size, production volumes and part design dimensions. Our goal is to design a photo tool with as many parts per sheet of metal as possible.PH PandaHall 20pcs Thin Aluminum Sheets 5mm Metal Sheet Aluminum Sheet Plate Flat Stock 3.9x3.9 Inch Unplated Aluminium Plate Material for Engraving Jewelry Making Hand Stamping Embossing Etching. . Fancyes Metal Etching Sheet Bending Photo Etched Parts Assembly Bender Modeling Tools. 4.6 out of 5 stars. 17. 50+ bought in past month. .49 .Etching – The metal sheet is immersed in an etchant solution (commonly ferric chloride) that reacts with the exposed metal areas and dissolves them. The hardened photoresist acts as a barrier that prevents the unexposed metal areas from being etched. Stripping – The remaining photoresist is removed from both sides of the metal sheet. The .

Chemical etching, also known as photochemical machining or photo etching, is a subtractive sheet metal machining process which uses chemical etchants to create complex and highly accurate precision components from almost any metal.Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing!Neutralizer removes etching solution residue from your metal marking surface after etching. Output. Etching Dp. Current: Voltage. Input Voltage. Plug Type: Cord Lg., ft. Includes . To make a stencil, print your message or logo on a transfer sheet, place it in the ultraviolet exposure unit with a sheet of stencil paper to transfer the image .

metal etching techniques

Comprehensive range of materials. Chemical etching can be applied to virtually any metal, regardless of its hardness or temper. Each year we process over 100 tonnes of sheet metal, encompassing over 2,000 metal types – more than any other chemical etching supplier.Framed Etching Aluminium Sheet Plate Metal Engraving Karlsruhe Schloss Castle Palace Badisches Landesmuseum Museum Germany $ 386.23. FREE shipping Add to Favorites Nu Gold Jewelers Brass Sheet 3"x3" (12.5k) $ 7.00. Add to Favorites 100 Pack Anodized Aluminum Business Card Blanks - Gold - Laser Engraving Blank Metal Cards CNC - 3.4in x 2.1in X 0 .

how to etch stainless steel

how do you etch metal

etching solution for metal

When deciding between a pre-engineered building or a weld-up building, the choice is really determined by your structural needs. Both building types offer customization and flexibility for the customer.

etching sheet metal|how to etch stainless steel