sheet metal box design for manufacturing During the design phase, fabricators utilize computer-aided design (CAD) software to create precise and accurate representations of the custom sheet metal boxes. CAD software enables them to visualize the final product, . Interesting. I burn .030in on my Miller 211. regardless of thickness. Don't have much experience on 110v vs 220v as I quickly realized I needed (wanted) 220v for 3//16 plus. That said, I need to to try thinner wire for sheet metal but I .

0 · simple sheet metal projects

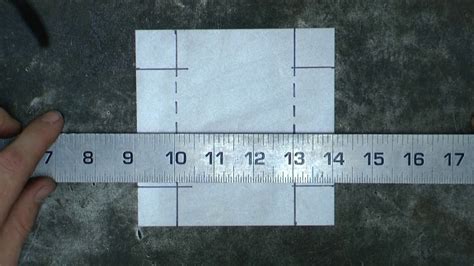

1 · sheet metal box layout

2 · sheet metal box fabrication

3 · sheet metal box drawing

4 · sheet metal box design template

5 · sheet metal box design guide

6 · free sheet metal project plans

7 · cool small sheet metal projects

Catalogue Measuring & monitoring systems – Solutions for smart machines, factories & grids Version 2022

The following are some design rules for slots and holes. Hole and slot in sheet metal design. 1. The minimum hole diameter should be ( Dmin) ≥ the thickness of the sheet .Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing . During the design phase, fabricators utilize computer-aided design (CAD) software to create precise and accurate representations of the custom sheet metal boxes. CAD software enables them to visualize the final product, . Based on some standard design for manufacturing practices, thorough analysis of results, and changing industrial requirements, the following are sheet metal design tips you should follow in your sheet metal fabricating .

simple sheet metal projects

sheet metal box layout

Specializing in custom design and manufacturing of metal enclosures, metal carts, metal bins, metal boxes, and metal cabinets for OEM manufacturers of all types of products. Over 65 years of manufacturing experience working with materials including sheet metal, tubing, rigid wire, aluminum and more. EXPLORE OUR PRODUCTS 2. Material Selection: Choose the right material based on the product’s end-use, cost, and manufacturing process. 3. Design for Assembly: Optimize design for easy assembly time. 4. Design for Manufacturing: Optimize design for efficient manufacturing. 5. Testing and Quality Control: Test the product and implement quality control. Design and Configuration of Custom Sheet Metal Boxes. The design and configuration of custom sheet metal boxes play a crucial role in meeting the specific requirements of a project. The design process involves several considerations, including material selection, dimensions, and shape. Material Selection

Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. . If you feel the need for a lid, like I show in some of the pictures, just repeat the same process but make the box slightly bigger overall, but .

Mastering sheet metal design is key to achieving both precision and efficiency in manufacturing sheet metal parts. By incorporating Design for Manufacturing (DFM) principles, you can streamline production, reduce costs, and maintain high-quality standards. Whether you’re working with steel, aluminum, or copper, understanding the nuances of sheet metal processing .Sheet Metal Design: The Future of Sheet Metal Design. With its long history of engineering and craftsmanship, sheet metal design is poised for a bright future. This discipline, rooted in tradition but propelled by technological advancements, is set to undergo transformational shifts that redefine its aesthetics and functionality.No single design tip can cover all the sheet metal mistakes we’ve seen, but this “best of” collection is a start. Take a look at our sheet metal design guidelines to keep you moving in the right direction. For additional help, feel free to contact a Protolabs applications engineer at 877-479-3680 or [email protected].

deep electrical wall box

sheet metal box fabrication

deep old work electrical box

2 Approved Sheet Metal’s Proven Approach to Corner Construction; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Metal Fabrication Corner Construction FAQ. 4.0.1 Why is proper corner construction crucial in sheet metal fabrications? 4.0.2 How does Approved Sheet Metal ensure high-quality corners in every fabrication?Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary operations and is far more costly. The purpose of custom sheet metal boxes is to offer efficient space utilization, protection for components or products, and the inclusion of additional features to enhance functionality. Importance and Benefits of Using Custom Sheet Metal Boxes. Using custom sheet metal boxes in precision fabrication projects offers several important benefits. Slots and Tabs for Weldment Components Picture a four-sided box with flanges that are 8” high. To weld the box’s corner seams, most shops apply clamps or other fixtures to hold the sides in place at the correct angles—a time-consuming task that can double the welding time. Adding slots & tabs to the box’s sides makes those sides self-fixturing, eliminating the .

Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are. fabricated from sheet metal.

Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, .Waters Design and Manufacturing is a leading specialist in custom metal fabrication, prototypes and design, providing custom metal products such as exhaust cabinets and booths, fume hoods, machine parts, glove boxes, and .Waters Design and Manufacturing 326 Main Street Fremont, NH 03044 Call 603.895.5255 Fax 603.895.5355 Contact Gary Waters ([email protected])SPECIALISTS IN CUSTOM METAL FABRICATION, PROTOTYPES AND DESIGN

Various hot and cold sheet metal forming techniques will also influence what metal is right for your design. Consider metal thickness. The thickness of your sheet metal will also affect your enclosure’s weight, strength, punch size, and flange length. If your enclosure needs to be small and lightweight, then choosing a thick sheet metal will .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts. It offers an in-depth analysis of sheet metal manufacturing tolerances, a critical aspect ensuring the consistency and quality of every piece manufactured. Each section of this guide is crafted to provide insights into the multifaceted world of sheet metal design and fabrication, from the initial design phase to production.

sheet metal box drawing

5 Sheet Metal Design for Manufacturing. 5.1 FREE eBOOK DOWNLOAD; 6 Optimal Sheet Metal Hinge FAQ. 6.0.1 What role does a hinge play in sheet metal fabrication, and why is selecting the right one important? . Often used for box assemblies and other permanent constructions, integrated/barrel hinges are formed onto the part itself. We can attach .

Our sheet metal design for manufacturing eBook is an essential guide for anyone looking to design parts that can be manufactured faster with less back and forth. This ebook provides an overview of best practices in sheet metal design of features and common design elements, including hems, offset, notches & tabs, welding, corners, uniform .

It has enormous potential in sheet metal manufacturing. This article focuses on the application of sheet metal design in laser welding of housing structures with flanged 45° beveled joints. Sheet metal design in the structure of laser welding box. The box body is made of 1.5mm thick 304 stainless steel and has dimensions of 200mm × 200mm × .

Supro MFG is an industry-leading custom metal box manufacturer in China, actively providing a full range of custom metal box manufacturing solutions according to various industry applications, environments, industry standards and functional requirements. . we specialize in the design and manufacture of custom sheet metal parts fabrication and . 1 Sheet metal fabrication for chassis, tanks, enclosures, and other sheet metal parts. 1.1 Solution 1: Back Bending; 1.2 Solution 2: Software and Custom Sheet Metal Dies; 2 Sheet Metal Design for Manufacturing. 2.1 FREE eBOOK DOWNLOAD; 3 Formed Sheet Metal Parts FAQ. 3.0.1 What is the best method for forming deep boxes or U shapes in sheet metal? Weldflow Metal Products provides high-quality sheet metal boxes and enclosures. Custom metal enclosures with powder-coated and anodized finishings are available. 1-866-848-3641

deep box electrical

Use our metal weight calculator to find the weight of metal, steel, or aluminum stock, and see the densities of common alloys.

sheet metal box design for manufacturing|sheet metal box layout