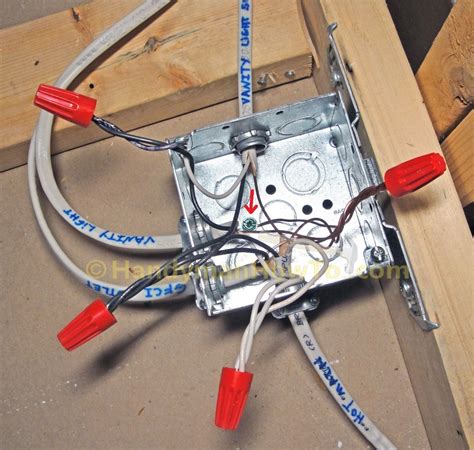

how to make a hole for wiring in electrical box In this video I'm making a holes. Holes in an electrical boxes. I have 5 different types of electrical boxes . Each is for different application. With Wago connectors the ONLY way of achieving a maintenance-free connection is to enclose the appropriate Wago connectors within a Wagobox. (The Wagobox is also only designed to accept certain types of Wago connectors to achieve MF certification.)

0 · metal junction box wiring diagram

1 · installing a metal junction box

2 · how to plug a junction box

3 · how to install a box

4 · hole knockout for electrical box

5 · electrical junction box installation

6 · electrical box installation

7 · cutting holes in electrical box

WAGO’s junction box helps you connect up to 60 conductors with WAGO’s 221 Series Splicing Connector for all conductor types with cross-sections up to 12 AWG (4 mm 2). When moisture meets electricity, a short circuit can happen quickly. Encapsulation is a proven solution.

In this video I'm making a holes. Holes in an electrical boxes. I have 5 different types of electrical boxes . Each is for different application. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on . Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the process to reinstating the IP. Instructional video on how to make a whole in a plastic back box. Brought to you by Alamo Property Solutions, you local handyman service in Norfolk, England..

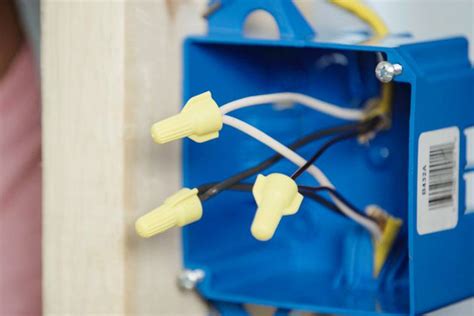

Separate the circuit wires at the existing splice and loosen the cables as needed to make room for the new junction box. Anchor the box to the framing (or other support structure) with screws driven through the factory . By understanding the function of junction boxes, using the right tools and materials, following a step-by-step guide, and avoiding common mistakes, DIY enthusiasts can tackle wiring projects with confidence.

Use a file to scrape a small notch or “weep hole” in the bottom edge of the box. This allows any water that gets into the box to drain. Next, strip the insulation off the wire ends. Attach the ground wire to the green screw in the . Make good connections by making hooks in the ends of the wires, wrapping them clockwise around the screws, and tightening them with a screwdriver. Do not use the back-stab holes in the receptacle, as they tend to .

I've found that you can break the old bakelite box apart with a punch, screwdriver, dowel, or similar tool thus leaving yourself some wiggle room. Pull your new wire into the Remodel box and insert it back into the wall. You . Tour Start here for a quick overview of the site Help Center Detailed answers to any questions you might have Meta Discuss the workings and policies of this site Extending a round electrical box may seem like a daunting task, but it doesn't have to be. With the right tools and a little bit of know-how, anyone can complete this job with great results. Whether you need to add outlets, switches, or any other electrical components, extending a round electrical box is a relatively straightforward process.

Push the box into the hole and tighten the ears against the drywall, leveling the box as you go. Strip the sheathing, leaving at least a quarter-inch inside the box. Strip about 3/4-inch of insulation off the white and black wires. In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil. This video shows how to cut a hole in plaster and lath for a new electrical box quickly without damaging the surrounding wall.

Cut the drywall to enlarge the hole, staying inside your new lines. The box should be snug. You can always make the hole bigger, never smaller. Feed the cables through the built-in cable clamps and insert the box into the hole. The NEC requires at least 1/4-inch of the exterior plastic sheathing to be inside the box.Drill a hole for new electrical location. Look in the ceiling, if you are lucky those joists may not be solid and you should be able to snake a fiber rods across to the other location. If that is the case, you will most likely have to remove the EL box on the other side to catch the fiber rods and pull it in. . In the attic cut your hole .

Pull your new wire into the Remodel box and insert it back into the wall. You may or may not have to enlarge the old hole to fit the new box. I realize you don't want to put in a new box but fishing a new wire can be a real pain. The plastic remodel box is virtually painless.

Home How to Make an Electrical Junction Box ShareShare An electrical junction box is one of the most important installations that you can set up in your home or business establishment for safety reasons. . make sure that the wires you intend to use are passing through the designated holes into the electrical box for the installation that . To protect the wiring and boxes, I'd use some painters tape (or even duck tape) to cover over each box to keep stray plaster out. While plaster in the box isn't a safety item, it can make your life more difficult because you may have to chip the dried plaster out to get wires to move where you need them to. It might clog up the device mounting .These little tabs sometimes stay connected to the box from the molding process. What I’ll do to make it easier to pull wires is pull up the tab a little bit with needlenose pliers. When they’re a little more flexible, it’s easier to get the wire in there. Another way is to use a flat-blade screwdriver.

metal junction box wiring diagram

If not you probably can rent one. They typically come in sets. You will need to drill a hole maybe 3/8" depending on the punch set. You then place the bolt through the die, then place the bolt through the hole you drilled, then thread the punch on the end of the bolt. Tighten with an appropriate wrench and it will give you the hole you need.

If there truly is no 10-32 tapped hole in the box, then I'd remove the grounding wires from the box mounting screws, nut them to a pair of 12AWG bare pigtails, and land one pigtail on the GFCI's grounding screw and the other on a self-drilling grounding screw (Garvin GSST or equivalent, note that it must be 10-32 UNF to meet NEC 250.6, coarse . Choose a location for your junction box that is easily accessible and complies with local electrical codes. The box should be mounted securely to a stud or joist, with its face flush to the wall surface. . the back of the box should have small holes for that purpose. . then the hot (black) wires, following the procedures outlined in Step 4 . The clamp bar inside the box is held by a screw. Could you remove and re-install these so that the screw draws the clamp bar up against the side wall of the box, rather than against the top of the box as it is now? The .

As long as you put a proper watertight connector and raceway in, punch as many holes as you see fit. I've been in electrical for 16 years, modifying the panel is expected half the time. Reply reply

I have cut hundreds of outlets into cabinets and it's not always fun. I used to have to use a jig saw but that caused too many problems. An oscillating tool .Summary: How to Install a Ceiling Fan Box and the Support with Photos: The example shows the flat ceiling fan box, a spanner bracket box the box marker for drilling the hole for the ceiling fan box, installing the wire and attic wiring, wiring to the ceiling fan box, measure for the ceiling fan box support, installing the ceiling fan support brace, the electrical wiring to the ceiling fan box . Electrical Extension wire Box: In this post, you will learn to make an extension box, containing 3 switches and three plug sockets. The circuit layout is as . The procedure of cutting of holes of appropriate size and fixing of switches and sockets on switch board is known as mounting of switches. There's a 2ft romex wire coming out of a hole in the wall. It used to extend to a light fixture in some nearby steps. I mounted the box next to the hole and routed the wire through a hole in the bottom of the box. –

You may need to cut a receptacle into the back of a cabinet. It often happens when installing cabinets for entertainment units. It's pretty easy to do if you. Hi in this video I'm showing how to install electrical metal back box in a solid brick wall. Hope it helps in your diy projects. Please subscribe for more vi.

I'd like to install this (Manufc. Page) 20A GFCI pop-up electrical box in the kitchen floor to allow cookware (microwave, blender, air fryer) to be plugged in.I will build a kitchen island cart to house the microwave and store the other cookware. I need to make a plunge cut for a hole through a 12"x12" 5/16"-thick ceramic tile and through the subfloor underneath to house the .

Take a piece of wood and make a hole in it with the hole saw for 1 1/4 pipe. Clamp it over the hole you need to make larger the wood will support the hole saw so it doesn't slide around. Another option is to try and use an 1 1/8 hole saw as the arbor for the hole saw for 1 1/4. Edit: sorry if that doesn't make sense. In this article, you will learn how to install a single gang electrical box in wood frame construction. This is from my electrical roughing-in series! The most important thing when roughing in is understanding your box heights, making sure the electrical box is sticking out the right depth, and using electrical scabs to create distance if needed.

installing a metal junction box

Use the deepest, largest box you can fit in the wall, with the most cubic inches. Metal boxes have more cubic inches than plastic boxes. "Masonry" boxes are huge, and well worth the trouble. Trim every wire that comes into that box to about 7" length. That allows you to fold the wire into the box with one 180-degree bend.

To add to the commenter, one such "long ass bit" is called a "cable drill bit" and are commonly used to drill holes through framing studs (etc.) to wire electrical through.

Quickfix JB4 Junction Box for Wago Connectors. Complies with BS5733 & 18th Edition wiring regulations; Maintenance free junction box; Made with high quality polypropylene material; Quick & secure cable slot for fast easy installation; Complied with IP20; No screw driver required; Flame retardant EN60598; Designed for Loop IN & 3 plate wiring

how to make a hole for wiring in electrical box|installing a metal junction box