diy cnc machine for wood Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting . Potential for White Rust: Prolonged exposure to moisture can cause white rust, a superficial corrosion that may affect appearance. . How to Choose the Right Galvanized Sheet Metal. 1. Consider the Environment: Choose a coating .

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

$611.99

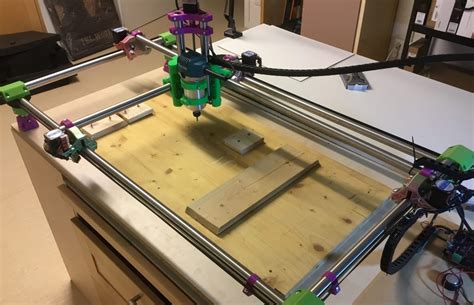

Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing .

Building a DIY CNC machine starts with careful planning and design. We will walk you through the key considerations, such as size, power, and precision requirements, as well as the different .This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables .

carbon steel sheet metal stamping parts

Rather than cutting metals like CNC mills, DIY CNC routers use less powerful routers as spindles to cut wood, as well as soft aluminum, plastics, foams, and sometimes glass. These tools let hobbyists embark on projects like:Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.Building a DIY CNC machine starts with careful planning and design. We will walk you through the key considerations, such as size, power, and precision requirements, as well as the different design options available. We will also discuss the different building materials you can use and their pros and cons. 3. Gathering Parts and Tools:\

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.

[David Taylor] needed a CNC router to do some more complex projects — so he did what any maker would do if they’re strapped for cash — make it from scratch! The impressive part of this build is.

Rather than cutting metals like CNC mills, DIY CNC routers use less powerful routers as spindles to cut wood, as well as soft aluminum, plastics, foams, and sometimes glass. These tools let hobbyists embark on projects like:Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.Building a DIY CNC machine starts with careful planning and design. We will walk you through the key considerations, such as size, power, and precision requirements, as well as the different design options available. We will also discuss the different building materials you can use and their pros and cons. 3. Gathering Parts and Tools:\

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.

make your own cnc mill

$24.99

diy cnc machine for wood|do it yourself cnc machine