electrical conduit box on airport building wall I'd use PVC in the walls to your boxes. Bring a heat gun in case you have to make some bends in your PVC. You can put tie wire through the holes in the back and wrap it . Sheet metal has ancient origins, but is an ever evolving industry that is vital to our modern world. Sheet metal fabrication relies on cutting-edge science and the hard work of millions of sheet metal workers.

0 · wiring block walls around box

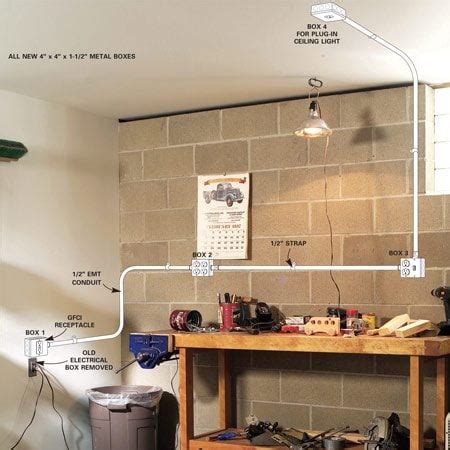

1 · surface mounted electrical conduit layout

2 · surface mounted electrical conduit

3 · surface mounted conduit wiring

4 · how to install surface mounted conduit

5 · diy electrical conduit layout

6 · block wall electrical box fitting

7 · block wall electrical box

I want to know where I can locate junction boxes (for housing wire nut splices from NM cable) in my attic. My house is real old and has every kind of wiring I can imagine, including knob and tube. The insulation is very deep and covers the top of the joists below.

For instance, you might bring Romex to the junction box, then run THWN wires outdoors through the "conduit as a wiring method" then transition . I'd use PVC in the walls to your boxes. Bring a heat gun in case you have to make some bends in your PVC. You can put tie wire through the holes in the back and wrap it .

Running electrical conduit on the surface of a wall is an easy way to add wiring to a workshop or garage. These DIY tips will help you get the job done. Nearly every commercial building with masonery walls and floors uses EMT unless RMC is required by code. You don't even have to use compression connectors, set screw .

Understand the different types of electrical conduit, including common types, rigid vs. flexible tubing, grounding boxes, what wiring to use, and why. The National Electrical Code (NEC) includes many specific requirements for installation of outdoor circuits and equipment. With outdoor wiring, the primary safety concerns involve shielding against moisture and .

When installing surface-mounted Electrical Metallic Tubing—a type of conduit—you want things to look neat. California electrician CJ Nielsen has some tips to make that happen. Follow his . For instance, you might bring Romex to the junction box, then run THWN wires outdoors through the "conduit as a wiring method" then transition back to Romex in the other building's junction box. However, in the conduit run, you must follow all the rules.

Choose a power source like a wall receptacle and run electrical metallic tubing (EMT) right on the wall to your new basement or garage workbench. EMT is often called 'thinwall conduit,' Thinwall conduit does not need to be threaded like rigid metal conduit (RMC).

I'd use PVC in the walls to your boxes. Bring a heat gun in case you have to make some bends in your PVC. You can put tie wire through the holes in the back and wrap it around a 6" piece of pvc to hold your box out. Re: Electrical Boxes in block walls Steve ` I have always used 4" Square by 2 1/8 deep box with an 1/8 or 1/4 plaster ring in block walls. As TKB stated if you work with the mason and mortar is installed around the box and plaster ring it will hold well. There are collar boxes available that have conduit KO's (knockouts). Just install one on top of the existing device box and run your conduit. This one is even better as it has more volume: Brand: Steel City, Part number:531511234UB. Here is a raised device cover to be used with the 4x4 box shown. Running electrical conduit on the surface of a wall is an easy way to add wiring to a workshop or garage. These DIY tips will help you get the job done.

Nearly every commercial building with masonery walls and floors uses EMT unless RMC is required by code. You don't even have to use compression connectors, set screw connectors are listed as concrete tight.

extenda-lite junction box

wiring block walls around box

I'm running 1/2" EMT conduit between single-gang surface-mount boxes. The holes for the boxes are slightly set away from the wall so that the conduit does not mount flush against the wall. I h. Understand the different types of electrical conduit, including common types, rigid vs. flexible tubing, grounding boxes, what wiring to use, and why.

The National Electrical Code (NEC) includes many specific requirements for installation of outdoor circuits and equipment. With outdoor wiring, the primary safety concerns involve shielding against moisture and corrosion, preventing physical damage, and managing issues related to underground burial. For instance, you might bring Romex to the junction box, then run THWN wires outdoors through the "conduit as a wiring method" then transition back to Romex in the other building's junction box. However, in the conduit run, you must follow all the rules. Choose a power source like a wall receptacle and run electrical metallic tubing (EMT) right on the wall to your new basement or garage workbench. EMT is often called 'thinwall conduit,' Thinwall conduit does not need to be threaded like rigid metal conduit (RMC).

I'd use PVC in the walls to your boxes. Bring a heat gun in case you have to make some bends in your PVC. You can put tie wire through the holes in the back and wrap it around a 6" piece of pvc to hold your box out.

Re: Electrical Boxes in block walls Steve ` I have always used 4" Square by 2 1/8 deep box with an 1/8 or 1/4 plaster ring in block walls. As TKB stated if you work with the mason and mortar is installed around the box and plaster ring it will hold well. There are collar boxes available that have conduit KO's (knockouts). Just install one on top of the existing device box and run your conduit. This one is even better as it has more volume: Brand: Steel City, Part number:531511234UB. Here is a raised device cover to be used with the 4x4 box shown. Running electrical conduit on the surface of a wall is an easy way to add wiring to a workshop or garage. These DIY tips will help you get the job done.

Nearly every commercial building with masonery walls and floors uses EMT unless RMC is required by code. You don't even have to use compression connectors, set screw connectors are listed as concrete tight. I'm running 1/2" EMT conduit between single-gang surface-mount boxes. The holes for the boxes are slightly set away from the wall so that the conduit does not mount flush against the wall. I h.

Understand the different types of electrical conduit, including common types, rigid vs. flexible tubing, grounding boxes, what wiring to use, and why.

surface mounted electrical conduit layout

extension box electrical outlet

$225.00

electrical conduit box on airport building wall|surface mounted electrical conduit