coining process in sheet metal animation This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing. From prototyping to production, Quickparts' manufacturing experts are ready to assist with all your CNC machining needs. Get a Quote Today.

0 · sheet metal working processes

1 · sheet metal operations pdf

2 · sheet metal coining process

3 · sheet metal coining machine

4 · sheet metal coining formula

5 · coining sheet metal video

6 · coining sheet metal bending

7 · coining sheet metal

Surface Finish-Precision Aluminum Parts made using CNC machining, 3D printing, and more. Brightstar Prototype CNC Co., Ltd offers bulk pricing for custom components. . Contact Surface Finish-Precision Aluminum Parts supplier for wholesale b2b price, customization or other inquiries . 1000KN Steel Bar Tensile Testing Machine LDT-I200 .

#CUPOLA#CASTING#WELDING

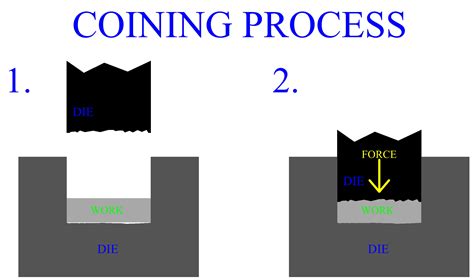

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o. This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation .

Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several .Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for .

Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it . Also using a press brake is the bending process known as coining. Coining is a high-performance bending process that’s characterized by greater force. Like air bending, it compresses sheet metal between a top die .

#CUPOLA#CASTING#WELDING

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o. This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

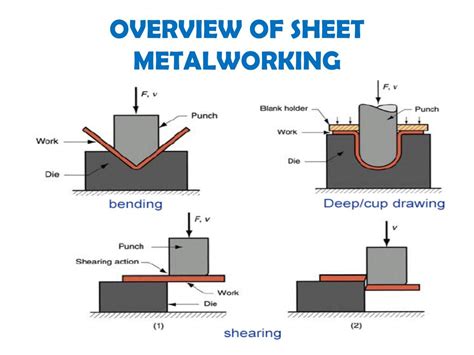

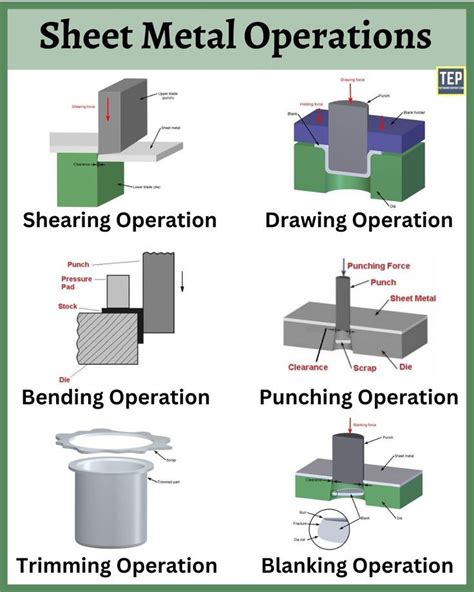

In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation. Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products.

Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press. Also using a press brake is the bending process known as coining. Coining is a high-performance bending process that’s characterized by greater force. Like air bending, it compresses sheet metal between a top die and a bottom die.#CUPOLA#CASTING#WELDINGIn this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.

This lecture describes the various sheet metal operations including ironing, coining, drawing, spinning, bending and embossing.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation. Coining. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages. It can produce sharp, crisp corners; well-defined features; and a brilliant surface finish.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products.

Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or more commonly, a hydraulically actuated press.

sheet metal working processes

metal clip in iphone 12 box

In this blog, we will explore the benefits of wholesale CNC machined PTFE parts, their applications, and how to select the right manufacturer for your business.

coining process in sheet metal animation|coining sheet metal bending