sheet metal material specifications The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss sheet metal materials, their advantages, and their limitations. We are dedicated to the production of high-quality custom metal fabrication with on-time delivery that meets or exceeds our customer’s satisfaction. Our team and facilities are equipped to handle all your needs within our footprint.

0 · which thickness called sheet metal

1 · types of sheet metal material

2 · standard thicknesses of sheet metal

3 · standard size of sheet metal

4 · metal sheet dimension

5 · how is sheet metal formed

6 · different types of sheet metal

7 · characteristics of sheet metal

you could get a smaller diameter pole, insert it a bit into one pole and use screws to secure it with a length sticking out, then slide the other pole over it and screw that down too.

The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss sheet metal materials, their advantages, and their limitations.But sheet metal parts design is done considering sheet thickness in mm. .

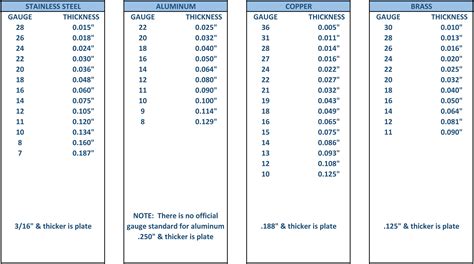

A sheet metal gauge or gage indicates the standard sheet metal thickness for a .These steel standards are helpful in guiding metallurgical laboratories and refineries, product manufacturers, and other end-users of steel and its variants in their proper processing and application procedures to ensure quality towards . In sheet metal fabrication, the standardization of material specification ensures consistency, safety, and compliance with industry standards. Utilizing references such as the American Society for Testing and .Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. . The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. The Manufacturers' Standard Gage provides the thicknesses for .

This comprehensive database includes thousands of current aerospace material specifications issued by SAE’s aerospace materials committees. New and revised standards are added to the database automatically upon publication, so database subscribers always have access to the most current information. Pricing based on number of users and locations.

1. Comply with metal roofing manufacturer’s Installation Guide applicable for the specified roofing system 2. SMACNA: Comply with Sheet Metal and Air Conditioning Contractors National Association’s “Architectural Sheet Metal Manual” unless specifically stated otherwise by roofing manufacturer’s printed material 3.

Metal sheet is metal or alloy stock supplied or available in the form of sheet or foil. It has a thickness between 0.006" and 0.250", and a width of 24" (609.6 mm) or more. How Metal Sheets are Made. Sheet metal can be designed and manipulated through a large number of processes which are grouped into different categories. Learn about the six imperative materials used in sheet metal fabrication. Discover their properties, applications and importance in the manufacturing process. Close; Articles . Dimensional Specifications: Thickness Range: 0.1 mm to 10.0 mm (Plates >10.0 mm are specialty items) Standard Widths: 1524 mm (5 ft) max, 1219 mm or 1250 mm (4 ft .Technical standards and manuals developed by SMACNA members have worldwide acceptance by the construction and code community, as well as local and national government agencies. ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and .

The 3003 H14 Aluminum Sheet, renowned for its excellent workability, weldability, and impressive corrosion resistance, is an alloy enhanced with 1.2% manganese, providing a tensile strength range of 17 to 30 KSI, making it a preferred choice for applications such as sheet metal work and fuel tanks.Low Carbon Steel 1008 is a mainstay material option in sheet metal fabrication. Containing less than .30% carbon, 1008 is formable, not prone to cracking, and its minimal carbon content provides weldability without the brittleness of a high carbon option. 1008 comes uncoated from the mill and is susceptible to corrosion, however it readily accepts coatings and finishings (such as .

D. Sheet Metal and Air Conditioning Contractors National Association (SMACNA): 1. Architectural Sheet Metal Manual (2003 edition). E. Underwriter's Laboratory (UL) Roofing Materials and Systems Directory: 1. Roofing Materials and Systems Directory listings and classifications of Underwriter's Laboratory roofing construction assemblies.

Understanding Sheet Metal Materials Types of Sheet Metal. Aluminum: Aluminum sheet metal is known for its lightweight yet strong properties, making it a preferred choice in the aerospace and automotive industries. . ensuring that the final product meets precise specifications. These tolerances are necessary in applications that require . The most commonly specified zinc coating found in HVAC sheet metal specifications is either G60 or G90, with G90 being the most common. G90 will last longer than a G60 coating. since G90 gives a thicker coating of zinc.

Sheet Metal Gauge Chart; Get a Quote. SECC steel. emma November 30, 2020 Steel Grades; Contents hide. 1 What is SECC? 2 SECC Material Specification. 3 SECC Steel Material Properties. 3.1 SECC Tensile Property: . SECC Material Specification. Element code: .Engineering Material Specifications Characteristics Ferrous Non-Ferrous Metals. Engineering Fundamentals Engineering Calculators Applications and Design . Sheet Metal & Wire Gauge Sizes Chart Sheet Metal Wire Gauge Sizes Table Chart ; Structural Shapes, Section Sizes Structural Shapes Steel, Aluminum ASTM, BS, EN, ISO Sizes .

Have you ever wondered what makes one metal sheet more suitable for stamping than another? Understanding the properties and specifications of various stamping materials is crucial for anyone in the . The mechanical properties of 3003 aluminum sheet make it an ideal material for many industrial applications. It has a modulus of elasticity of 10,000 ksi and a shear strength of 14,000 psi. These properties, along with its superior formability and welding performance, contribute to its widespread usage.

which thickness called sheet metal

Thickness of Metals Perforated Metal Spec Information Sheet. Steel: Use “Manufacturers” Standard Gauge for steel sheets. Stainless Steel: Use the U.S. Standard Gauge Table. Monel: Use the U.S. Standard Gauge Table. Copper, .produced in the same material finish as the adjacent panels but will be provided in minimum .040” thickness or 24 ga 304 2B Stainless steel. 3. Coping: Wall copings will be produced with the same material as the wall panel system unless otherwise noted. Sheet Metal Flashing extensions will be acceptable in non- viewing areas in accordance withSheet metal of iron and other materials with high magnetic permeability, also known as laminated steel cores, has applications in transformers and electric machines. Historically, an important use of sheet metal was in plate armor worn by cavalry, . Even though incoming sheet coil may meet tensile test specifications, high rejection rate is .There are many combinations of Steel Plate and Sheet types and finishes. From types such as A36 or 516-70 to finishes from hot rolled to cold rolled. . Steel sheets and plates are made by rolling a slab of steel through a series of rollers until the desired thickness and material properties are achieved. Each stage in the rolling and .

Determine the bend allowance for sheet metal based on material type, thickness, bend angle, and inside radius. Input the material details and bend specifications to calculate the bend allowance accurately. Converting Sheet Metal Gauge to Thickness. Convert sheet metal gauge to thickness in inches or millimeters for accurate measurements.MAT1011-86979054_C - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides specifications for low carbon hot rolled steel sheet and strip for CNH. It covers two grades - Grade A is the preferred grade for commercial quality steel that can be bent, formed, welded and moderately drawn. Grade B is a drawing quality steel that is fully . 2 Best Practices for Obtaining Internal Specification Documents; 3 Sheet Metal Design for Manufacturing. 3.1 FREE eBOOK DOWNLOAD; 4 Metal Fabrication Internal Specification Documents FAQ. . Companies change their internal specifications as materials, technologies, and requirements evolve. Keep the line of communication open with your contact . Sheet metal refers to metal that has been formed into thin, flat pieces, typically with a thickness of less than 6 mm (0.24 inches). It is generally produced through an industrial process. Sheet metal is available in various materials, including steel, aluminum, copper, brass, and stainless steel, among others.

Japanese Industrial Standards (JIS) are used to define the specifications and testing methods for metal materials in Japan. JIS standards emphasize high precision and quality, making them particularly relevant for industries that demand the highest manufacturing standards, such as electronics and automotive production. Versatile Electric: A cost-effective option for low-volume operations and a wide range of materials. In . Choosing the right sheet metal folding machine is a symphony of material specifications and machine capabilities. By carefully considering these elements, you can orchestrate a seamless fabrication process that harmonizes with your specific .Material Specifications for Steel Sheet Metal: A366: Cold Rolled Commercial Quality A569: :Hot Rolled Commercial Quality A570: Hot Rolled Structural Quality A526: Zinc Coated (Galvanized) Steel A526/A527: Galvanneal A591: Electrolytically Zinc Plated. Mechanical Tolerances ASTM ANSI Steel Sheets .

oem sheet metal

oem ftth distribution box factory

WELDING AND METAL FABRICATION employs a unique hands-on, project-based learning strategy to teach welding skills effectively and keep you motivated. This groundbreaking new book connects each welding technique to a useful and creative take-home project, making exercises both practical and personal—and avoiding the tedium of traditional .Metal fabrication and welding shop based in Virginia Beach, VA. Serving the greater Hampton Roads and surrounding areas with high-quality workmanship and customized products. .

sheet metal material specifications|standard size of sheet metal