cnc milling parts material Explore RapidDirect’s CNC machining materials, from metals to plastics, perfect for prototypes or custom parts. Find the right fit for your project with ease. Capabilities. CNC Machining. . Strong and corrosion-resistant, titanium is ideal for aerospace, medical implants, and high-performance parts in CNC machining. There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

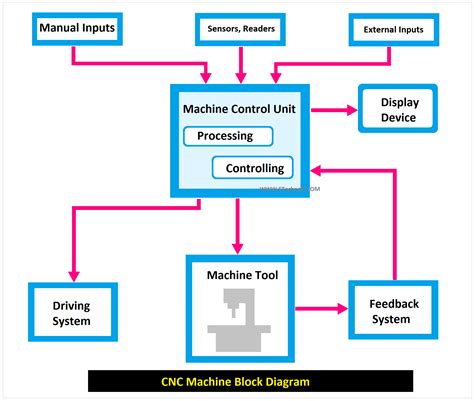

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

A hardwired smoke alarm installation involves wiring one of the smoke detectors (closest to the voltage source) to a 120 VAC breaker in the main electric panel or tapping from a 120 V electrical box, wiring it using a 14/2 .

A Guide to CNC Machining Materials Selection. With a universe of metal and plastic options, keep in mind functionality when choosing materials for machined parts. Choice is good. In most cases, the more options you have, the better your chances of getting exactly what you are looking for.Narrowing Material Options for CNC Machining. With a universe of metal and .Explore RapidDirect’s CNC machining materials, from metals to plastics, perfect for prototypes or custom parts. Find the right fit for your project with ease. Capabilities. CNC Machining. . Strong and corrosion-resistant, titanium is ideal for aerospace, medical implants, and high-performance parts in CNC machining.

metal gear solid box girl sticker

CNC Milling is an automated machining process used to manufacture 2D and 3D cnc parts by removing material from raw stock. Workshops use CNC milling machines to save time and improve manufacturing productivity. To make a .Size: While machining can produce parts in a range of sizes, part size can be limited by the maximum available size of a particular stock material. . Choosing metal or plastic materials for CNC machining can be an embarrassment of .

Discover perfect CNC machining materials for project needs! From metals to plastics and beyond, make informed choices for optimal results. Skip to content. [email protected]. Call Us Today! (+86) 188-2253-7569. . Best CNC Machined Parts Manufacturer and Factory in China. Custom Machined Parts Materials Home CNC machining has not too many restrictions on CNC material list. Common plastics, metals, or special materials can be processed, but the processing difficulty is different, the selection of CNC machining cutting tools material and the processing parameters of machine tools are different, and the processing cost is different. .Used for CNC machining aircraft parts, thanks to its high strength, and good machinability. Aluminum 5083: Ideal for CNC machining marine components due to its excellent corrosion resistance and high strength. Aluminum 6063: Often used in CNC machining architectural profiles and extrusions, provide good formability and surface finish. Aluminum 5052

Accompanied by swiss and micromachining techniques, they can achieve tolerances as tight as 0.0005 inches, making them ideal for high-precision copper parts. CNC milling services, specializing in cnc machining copper materials, can create a wide array of copper components such as: adapters; shafts; pinions; brackets; connectorsThe extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector. . Polycarbonate demonstrates compatibility with overmolding processes, allowing it to be combined with other materials to create hybrid parts with enhanced functionalities. Overmolding PC with .

It is widely used in CNC machining for automotive parts, electronic enclosures, consumer products, and prototypes. 6. UHMW-PE. . Choosing the right CNC machining material is crucial for ensuring the quality of your parts and meeting the demands of your production projects. To help you navigate the material selection process effectively, we .Whether it involves precision Milling (3-, 4-, or full 5-axis), detailed Turning, or expert Post-Processing, we're equipped to handle your most complex projects. Direct Delivery to You. We serve customers in every corner of the world. Parts are delivered directly to your doorstep from our CNC machining factory, ensures your custom parts arrive . Flipping the parts back and forth and back and forth is a waste of time, but many shops still do it because they don't know any better. By far the EASIEST way to deal with material that has stress in it is to stress relieve the material via a furnace operation and not by a machining operation. Next step is to use cutting and work holding methods that do not induce any .Online CNC Machining Services: Offering Turning, Milling, and Wire EDM. . and Wire EDM. Discover our CNC machining capabilities, available materials, and surface finish options. JLC Other Services: JLC3DP - 3D Printing JLCMC - Mechatronic Parts . advanced CNC machine shops • Parts as Fast as 3 days. Request a Quote Now CNC Machining .

Custom PE parts, delivered in 5 days. Reliable quality, expert support, and flexible options to fit your project needs. . The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector. . Polyethylene (PE) is a versatile material widely used in injection molding . The Best Packaging Material For CNC Milling Parts . Because collisions are inevitable during shipping and transportation, packaging solutions with a high buffering capability are utilized to diminish excessive transportation losses. When it comes to friction, they will contact and generate friction during handling or transit if they are not .

In CNC machining, selecting the appropriate hardness testing method depends on factors such as the material type, surface condition, and desired level of accuracy. By understanding the principles and applications of .

Read-on to understand the parts of a CNC milling machine and their functions. Also know about different accessories and tools used with milling machines. . For machining softer materials like aluminum, plastic, wood, or . In CNC machining, there are two primary types of milling machines: the vertical milling machine, with a Bridgeport milling machine being an excellent example, and the horizontal milling machine. Although the milling operations .What Types of Materials Can Be CNC Machined? Introduction: The Versatility of CNC MachiningCNC machining stands as a cornerstone in modern manufacturing. Its ability to shape a vast array of materials into precise parts makes it indispensable. This process adapts seamlessly to metals, plastics, and even composites. Let's delve into.

One of the most important aspects of CNC machining is choosing the right materials for the job. In this guide, we will explore various CNC machining material options, their properties, and suitable applications. Material Selection: Key Considerations . When selecting materials for CNC machining, manufacturers must consider several factors . CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily.CNC milling is a technology of computer-controlled (CNC) machining. It uses a cutter to remove material from a solid workpiece. The commonly used CNC milling machines in the industry are of two types: 3-axis (X, Y, Z orientation) 5-axis (X, Y, Z + .

Explore our Polypropylene (PP) Injection Molding Service, material options, and capabilities in making an effective industrial solution. Capabilities. CNC Machining. . If you want to produce high-quality machined parts with a sleek appearance, it’s essential to consider some critical factors related to CNC machining. . CNC machines can execute a variety of manufacturing processes, including: CNC drilling, CNC milling, CNC turning, CNC EDM Cutting, CNC Gear Hobbing, and CNC grinding. CNC machines produce parts rapidly and reliably with high accuracy and precision , and can create complex shapes that would be difficult or impossible to accomplish manually.CNC milling uses a variety of cutters to remove material from a piece of material to create a three-dimensional object. Milling machines are generally classified as horizontal or vertical depending on the direction in which they move (horizontal machines move back and forth along their X axis; vertical machines move up and down along their Z axis).

While it’s a common method for removing material, it can also result in defects in CNC milling parts. Understanding these defects, their causes, and how to address them is crucial for producing high-quality machined parts. . The dents can be caused by aggressive cutting parameters, improper tool selection, machining material, and machine .

CNC Machining Services. Surface roughness Ra 0.8-3.2 µm; Precision shop tolerance ±0.0004 in. (0.01mm) 5 Axis machined prototype parts in as fast as 1 day Common metal materials for CNC machining parts: Titanium, Bronze, Brass, Copper, Aluminum, Stainless Steel (303、304、316、17-4, Inconel 625 & 718), Zinc, Magnesium. 2. Plastics . Plastics are also popular materials in CNC machining. They are lightweight, durable, and have good machining properties. Acrylic, Polycarbonate, Nylon, and .

schematic diagram of cnc machine

If it's receiving the conduit (metal or not) that goes luminaire (niche or no-niche), it needs to be "listed, labeled, and identified as a swimming pool junction box." The only exception is if the lights were LV things connected by cord rather than conduit.

cnc milling parts material|homemade cnc parts