application of 5 axis cnc machine 5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move . From its start as Wichita Sheet Metal Works in 1909, WSM Industries has grown to become the Midwest’s regional leader in HVAC supplies and custom metal fabrication, serving a 10-state area through 6 different locations.

0 · haas 5 axis cnc machine for sale

1 · affordable 5 axis cnc machine

2 · 5 axis cnc milling machine for sale

3 · 5 axis cnc machine specifications

4 · 5 axis cnc machine price uk

5 · 5 axis cnc machine manufacturers

6 · 5 axis cnc machine hobby

7 · 5 axis cnc machine for sale

A combination of materials (metal alloys and carbon composites) on the wing’s leading edge revealed optimal performance at different flight regimes. The use of lightweight composite materials on critical structural components has made recent aircraft ultra-fuel-efficient.

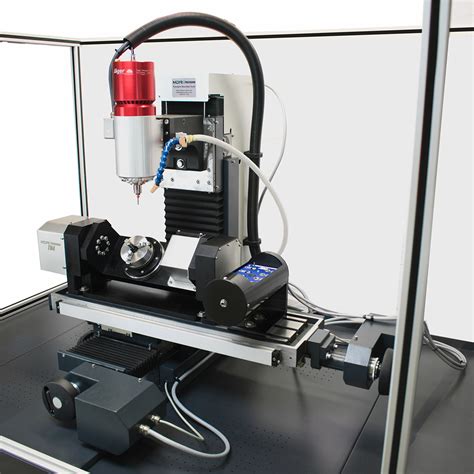

Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes . A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it . 5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move . Applications of 5-Axis CNC Machining 1. Aerospace Industry. The aerospace industry requires precise and reliable components, making 5-axis CNC machining an ideal choice for manufacturing engine parts, structural .

In this article, learn how 5 axis CNC machining works and its applications, benefits, and limitations. 5 axis CNC machining is a versatile and advanced manufacturing process that is applied in numerous industries due to its ability . 5-axis CNC machining is quick and efficient, offering a “one and done” approach. In a 3-axis machine, you would have to manually rotate the part in between passes so the cutting tool could access all of the faces.

There are two main types of 5-axis CNC machines, indexed 3+2-axis and continuous (full) 5-axis. By adding B-axis rotates with Z-axis and working with X, Y, Z, and C axes, 3 plus 2-axis CNC machining starts producing parts with . We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the .

5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and . Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes simultaneously, it transcends the capabilities of . Common Applications of 5-Axis CNC Machining. This manufacturing process is suitable for applications in several industries requiring high precision, complex shapes, and tight tolerances.

A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision. 5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move across the X, Y, Z linear axes, as well as rotate on the A and B axes to approach the workpiece from any direction. Applications of 5-Axis CNC Machining 1. Aerospace Industry. The aerospace industry requires precise and reliable components, making 5-axis CNC machining an ideal choice for manufacturing engine parts, structural components, and satellite and spacecraft components.

In this article, learn how 5 axis CNC machining works and its applications, benefits, and limitations. 5 axis CNC machining is a versatile and advanced manufacturing process that is applied in numerous industries due to its ability to produce . 5-axis CNC machining is quick and efficient, offering a “one and done” approach. In a 3-axis machine, you would have to manually rotate the part in between passes so the cutting tool could access all of the faces.

There are two main types of 5-axis CNC machines, indexed 3+2-axis and continuous (full) 5-axis. By adding B-axis rotates with Z-axis and working with X, Y, Z, and C axes, 3 plus 2-axis CNC machining starts producing parts with tight tolerance.

We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications.5-axis machining is a specific type of CNC machining that enhances the traditional 3-axis approach. This electromechanical process controls tools across five axes with high accuracy and precision to cut away excess material and produce components and parts. Among them, the 5-axis CNC machine stands out as a transformative tool, granting unparalleled precision and flexibility in complex machining tasks. By providing movement along five different axes simultaneously, it transcends the capabilities of .

haas 5 axis cnc machine for sale

Common Applications of 5-Axis CNC Machining. This manufacturing process is suitable for applications in several industries requiring high precision, complex shapes, and tight tolerances.

A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision. 5-axis machining refers to a high-precision CNC (Computer Numerical Control) multiaxis machining process that operates along five different axes simultaneously. This advanced method allows the cutting tool to move across the X, Y, Z linear axes, as well as rotate on the A and B axes to approach the workpiece from any direction. Applications of 5-Axis CNC Machining 1. Aerospace Industry. The aerospace industry requires precise and reliable components, making 5-axis CNC machining an ideal choice for manufacturing engine parts, structural components, and satellite and spacecraft components.

In this article, learn how 5 axis CNC machining works and its applications, benefits, and limitations. 5 axis CNC machining is a versatile and advanced manufacturing process that is applied in numerous industries due to its ability to produce .

5-axis CNC machining is quick and efficient, offering a “one and done” approach. In a 3-axis machine, you would have to manually rotate the part in between passes so the cutting tool could access all of the faces.There are two main types of 5-axis CNC machines, indexed 3+2-axis and continuous (full) 5-axis. By adding B-axis rotates with Z-axis and working with X, Y, Z, and C axes, 3 plus 2-axis CNC machining starts producing parts with tight tolerance. We will explain what 5-axis machining is, detail how the process operates, and break down the functions of the different axes. Additionally, you will learn about the advantages and disadvantages of utilizing this machining technique, as well as its common applications.

affordable 5 axis cnc machine

The cable with the white wire that's connected to the two black wires is a switch loop: Normally wires with white insulation are used only for neutrals, but code makes an exception to allow for use of the white wire in a cable used as a switch loop as a hot rather than a neutral.

application of 5 axis cnc machine|5 axis cnc machine for sale