sheet metal chassis Custom Electronic Enclosures, Sheet Metal Parts & CNC Machining for Scientists, Engineers and Innovators ✓ BUILT IN TWO - THREE DAYS* ✓ NO MINIMUM ORDERS . Shop durable plastic or aluminum IP68 enclosures for protection in wet and dirty environments. Protect electronics with waterproof IP68 junction boxes!

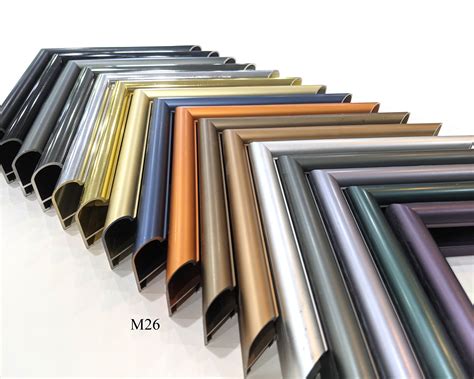

0 · unique metal picture frames

1 · metal enclosures for electronics

2 · metal enclosure box for electronics

3 · metal chassis gaming laptop

4 · metal chassis box electronics

5 · handmade metal wall picture frames

6 · chassis components and their function

7 · bud chassis and enclosures

$8.88

1929 ford model a sheet metal

unique metal picture frames

Custom Electronic Enclosures, Sheet Metal Parts & CNC Machining for Scientists, Engineers and Innovators ✓ BUILT IN TWO - THREE DAYS* ✓ NO MINIMUM ORDERS .Once you have a design and a quote, you can order your custom electronic . Sheet Metal Chassis and Assembly Fabrications. Approved Sheet Metal (ASM) excels at fabricating custom sheet metal chassis. We understand .

metal enclosures for electronics

Metal selection. As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used .

Protocase is a custom sheet metal enclosure manufacturer providing a 2-3 day turnaround, with no minimum orders. Offering the highest level of quality in custom fabrication, we build .Our general use electronic enclosures include sheet metal enclosures, chassis, hand-held enclosures, breadboards and more. Plastic › Steel › Alumimum › See More

Choose from a line of products that are perfect for a wide range of industrial and desktop applications. Depending on the model, our sheet metal enclosures are suitable for wall . Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much smaller than its length. Due to its special geometry and small thickness, it has the advantages of small. Sheet metal parts are commonly referred to as sheet metal parts. Sheet metal refers to a metal plate whose thickness is much .

There are three main processes: cutting, bending and assembly. Other processes include punching, folding and stretching. Sheet metal fabrication is a common manufacturing method for enclosures within computers. Metal enclosures are commonly used in various industries to protect electronic components, machinery,. The dimensional accuracy of sheet metal in deep drawing should not be too high. At the same time, because of the change of the wall thickness of the sheet metal part, the sheet metal part can only ensure the internal or external dimensions of the feature during deep drawing, but not its internal and external dimensions at the same time. Designing a sheet metal enclosure requires attention to detail and consideration of various factors to ensure the final product is functional, manufacturable, and cost-effective. Here are some key tips to guide you through the process: 1. Material Selection Choose the. Sheet Metal Chassis Supplier Menu. Close Menu. Home. About us. MFG Guide. Technology News. Contact us. Sheet metal bracket. MFG Guide Yan yifan — 2022-07-14 .

The purpose of crimping is to smooth the sharp and rough sheet metal edges to meet the use requirements of the project. Bend. Bending is another common sheet metal forming process. Manufacturers usually use brake press or similar mechanical press for metal bending. The sheet metal is placed on the die, and the punch is pressed down on the sheet . I am currently designing a sheet metal chassis for next years competition, and would like some help. I have a couple of questions: 1: What thickness of sheet metal should i use? I currently have .060", but I am not sure what thickness would be the optimum balance between lightness and strength. 2: Should I use a round or cross hatch style .Our custom sheet metal chassis service are of the highest quality and most affordable prices. Finish the parts in time to provide the strongest support for your R&D projects. Do sheet metal manufacturing according to your drawings or samples; We offer customers full-service sheet metal fabrication and related capabilities from design to delivery. The location is excellent and thetransportation is convenient. We have rich experience in sheet metal fabrication,Wongsam Sheet Metal is a a reputable supplier. Our company has advancedproduction equipment and skilled front-line employees. we are mainly engaged in theproduction and sales of sheet metal parts, metal chassis, metal cabinet etc. More

Sheet Metal Chassis Supplier Menu. Close Menu. Home. About us. MFG Guide. Technology News. Contact us. Battery shell of electric vehicle. MFG Guide Yan yifan — 2022-07-04 . Sheet Metal Chassis Supplier Menu. Close Menu. Home. About us. MFG Guide. Technology News. Contact us. What are the costs for sheet metal processing. Technology News Jiatong — 2021-12-16 . Surface treatment of hardware: generally, there are painting and electroplating, which are used to prevent rust and form a protective film and anti-static on the surface. IV. special instructions for the internal design of the chassis: the high-quality chassis is.Custom Sheet Metal Part Stamping Fabrication Stainless Steel Aluminum Aluminium Enclosure Housing Case Box Shell Cover Chassis Sheet Metal Parts. Fully finished precision sheet metal parts such as brackets, plates, frames, arms, bus bars, fixtures and more. . How TruGolf found durability and beauty with its Protocase-made tracking system chassis. Motherboard Design Guide. Download our comprehensive guide on integrating standard motherboards into your enclosure design ..80-.50 Min. Order: 2000 pieces

Designing a metal enclosure involves several key steps to ensure it meets functional, structural, and aesthetic requirements. Here’s a detailed guide to help you through the process: Step 1: Define Requirements Dimensions and Shape: Determine the size and shape of.

Designing a metal enclosure involves several steps to ensure that it meets the required specifications for protection, functionality, and aesthetics. Here’s a step-by-step guide to designing a metal enclosure: 1. Define Requirements . Sheet metal cutting is a fundamental step in manufacturing, where flat metal sheets are cut into specific shapes and sizes. The cutting method depends on factors like material type, thickness, and the complexity of the design.Here are the .

Some old group of sheet metal processing engineers like to use AutoCAD as the planning software of sheet metal chassis cabinet sheet metal part product model, and introduce parametric skills. The features have the nature of parameterization, and their features are expressed in the way of parameters. Engineers establish a feature library in .Sheet Metal Chassis are support structures that must be closed or securely fastened during use. Manufactured with advanced CNC machining to ensure dimensional and structural accuracy. Frames are available in customizable structures and dimensional configurations to meet your needs. It is highly appreciated for its sturdy structural structure . Sheet Metal Chassis Supplier Menu. Close Menu. Home. About us. MFG Guide. Technology News. Contact us. Characteristics of laser cutting. MFG Guide Yan yifan — 2022-05-16 .Precision is such an important aspect of our company that we put it right there in our company name. Dongguan Jiatong Precise Metal Products Co. is a professional sheet metal fabricator providing customers with a comprehensive range of sheet metal fabrication solutions, including cutting, forming, welding, finishing, silk screening, and assembly.Facility Founded in 2011, .

At present, sheet metal chassis processing has become a more prominent processin. Do you know the tips of sheet metal processing? 2022-03-31. In order to avoid personal injury caused by broken chips, open baffles shall be . Precautions for using hand hammer in sheet metal processing 2022-03-31.Hebei Xingsheng Communication Technology Co., Ltd.|Sheet Metal Chassis|Communication Equipment-Hebei Xingsheng Communication Technology Co., Ltd. is a professional manufacturer engaged in the development, design, manufacturing and sales of sheet metal chassis and communication equipment. Since its establishment, the company has continuously introduced .

metal enclosure box for electronics

1、 Compared with forgings, sheet metal parts are lighter, save a lot of metal materials, the process flow is not complex, and the production cost is lower. 2、 Sometimes the sheet metal will be deformed after dry connection, so it is important to choose the appropriate material; During dry connection, the plate needs to be heated evenly; Pay attention to the .

metal chassis gaming laptop

However, the process flow of sheet metal parts and chassis sheet metal with different structures may also be different. The following is a basic process flow of sheet metal processing industry. Sheet metal processing process: sheet metal design → technical drawing → drawing unfolded drawing (NC programming) → blanking (Digital punching . Sheet metal connection mainly adopts welding, threaded connection, riveting and bonding. Welding; It is a process method for overall or local heating of weldments or plastic deformation of weldments, or plastic deformation and heating are carried out at the same time to realize lasting connection. Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal. Functionality: Purpose of the .

18 mini sheet metal bender

1900 box electrical

When you purchase a metal structure, one of the key decisions you will need to make is the shape of the roof. One popular style of roof for metal buildings is a single slope roof. In this guide, we’ll go over the pros and cons of this roof shape so you can decide if it is the right one for your needs.

sheet metal chassis|metal enclosure box for electronics